Operating parameters, Liquid phase storage – Taylor-Wharton KRYOS Controller User Manual

Page 12

10

KRYOS

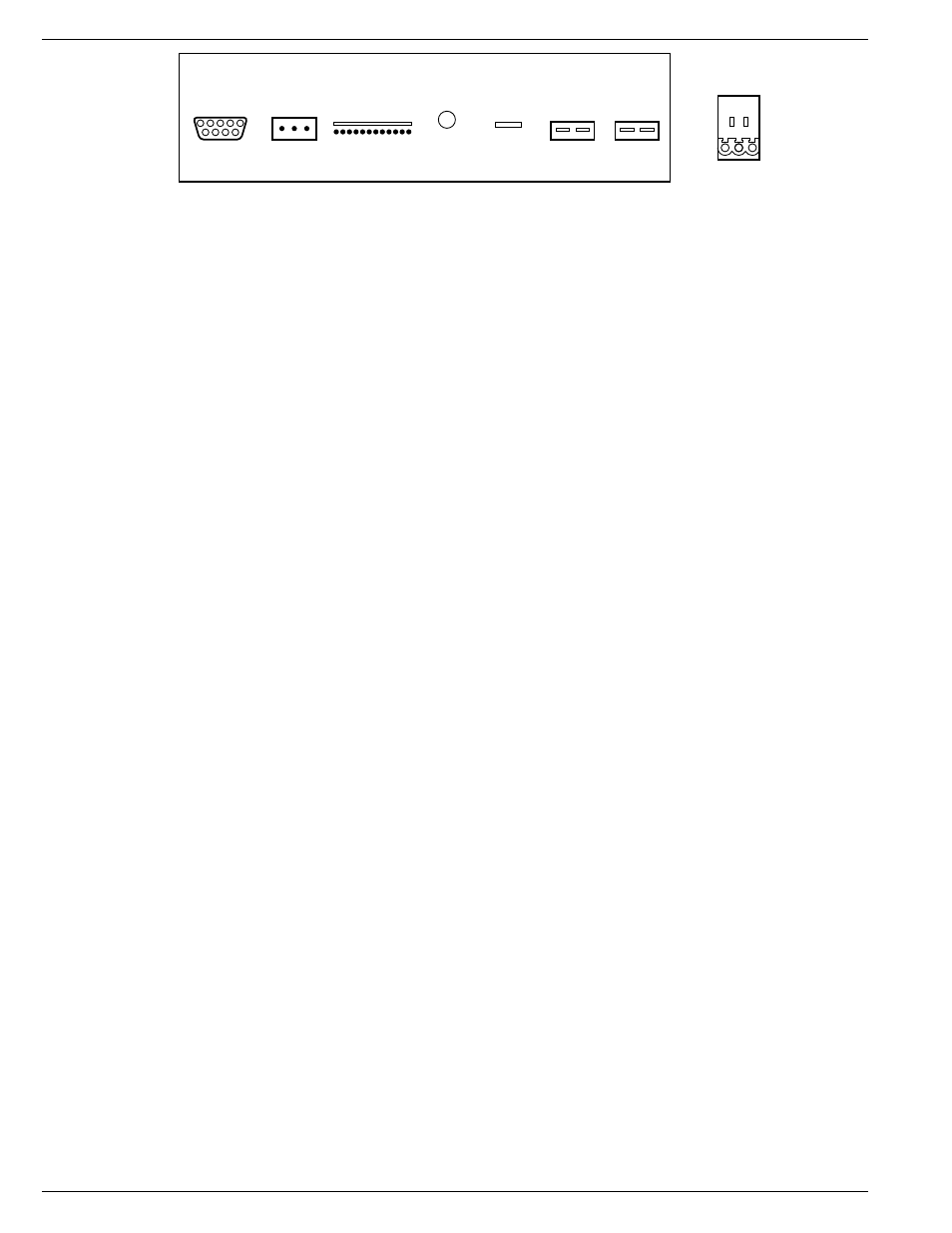

Comm Port

(RS-232)

Remote

Alarm

Remote Alarm:

Normal Condition............. Continuity Between pins 2 and 3

Alarm Condition................. Continuity Between pins 1 and 2

Sensor

24 VAC

Power

Solenoid

Temp 1

(Receptacle

View)

Temp 2

3

1 - Purple Wire: Normally Closed

2 - Orange Wire: Normally Open

3 - Grey Wire: Normally Open

2 1

Figure 5.0 Remote Alarm Plug Connection

Operating Parameters

When materials are immersed in liquid nitrogen, they will assume the temperature

of the liquid (-196°C/-320°F). When material is stored in the vapor phase over the

liquid, the liquid nitrogen is still a very cold refrigerant, but the refrigerator’s interior

temperature increases somewhat as product is stored higher over the liquid. This

temperature differential is not significant in many biological storage applications,

and is affected by the amount of product stored in the refrigerator, the type and size

of inventory control system, and the liquid level in the unit.

The liquid level in the refrigerator is determined by the position of the of the

Thermistor Assembly in the sensor tube. These sensors are set at installation to

maintain a specific liquid level. A filling cycle is initiated when the level falls below

the Start Fill sensor and is completed when the Stop Fill sensor is reached. This

filling cycle repeats when the level fall below the Start Fill sensor. Sensor Probe

assignments may be changed on the controller keypad to define new start and stop

levels, and these levels may be set independently to vary the liquid level differential

between fills. Prior to the initial fill of the refrigerator, a determination should be

made whether vapor phase or liquid phase storage will be utilized.

All units are supplied with a seven thermistor assembly and a freeze-guard sensor

unless otherwise specified. Factory setting positions for the K-Series are Start Fill 3 in.

(76.2 mm) and Stop position 6 in. (152.4 mm). The LABS factory setting positions

will maintain liquid level within a distance of 2 in. (50.8 mm) from the bottom of the

operating tray on the LABS 20K, 38K, 40K, 80K units, and 3 in. (76.2 mm) from the

bottom of the operating tray on the LABS 94K.

Liquid Phase Storage

Liquid phase storage is normally utilized when liquid nitrogen temperatures are

required to maintain stored product viability and the storage medium is adequate

for storage in liquid nitrogen.

In a typical liquid phase storage system, the liquid level sensors are positioned to

maintain the liquid level at or below the top level of the inventory control system.

During operation, the upper levels of the inventory control system will at times

become exposed as the liquid level fluctuates.

Care must be taken to ensure that the liquid level remains below the bottom of the

refrigerator lid. Exposure to liquid nitrogen may result in physical damage to the lid.

Additionally, operating the refrigerator with high liquid levels characteristic of liquid

phase storage may result in turbulence during fill cycles. Caution must be exercised

if the refrigerator lid is opened during a fill, and appropriate safety equipment

should always be worn.

10

KRYOS

Comm Port

(RS-232)

Remote

Alarm

Remote Alarm:

Normal Condition............. Continuity Between pins 2 and 3

Alarm Condition................. Continuity Between pins 1 and 2

Sensor

24 VAC

Power

Solenoid

Temp 1

(Receptacle

View)

Temp 2

3

1 - Purple Wire: Normally Closed

2 - Orange Wire: Normally Open

3 - Grey Wire: Normally Open

2 1

Figure 5.0 Remote Alarm Plug Connection

Operating Parameters

When materials are immersed in liquid nitrogen, they will assume the temperature

of the liquid (-196°C/-320°F). When material is stored in the vapor phase over the

liquid, the liquid nitrogen is still a very cold refrigerant, but the refrigerator’s interior

temperature increases somewhat as product is stored higher over the liquid. This

temperature differential is not significant in many biological storage applications,

and is affected by the amount of product stored in the refrigerator, the type and size

of inventory control system, and the liquid level in the unit.

The liquid level in the refrigerator is determined by the position of the of the

Thermistor Assembly in the sensor tube. These sensors are set at installation to

maintain a specific liquid level. A filling cycle is initiated when the level falls below

the Start Fill sensor and is completed when the Stop Fill sensor is reached. This

filling cycle repeats when the level fall below the Start Fill sensor. Sensor Probe

assignments may be changed on the controller keypad to define new start and stop

levels, and these levels may be set independently to vary the liquid level differential

between fills. Prior to the initial fill of the refrigerator, a determination should be

made whether vapor phase or liquid phase storage will be utilized.

All units are supplied with a seven thermistor assembly and a freeze-guard sensor

unless otherwise specified. Factory setting positions for the K-Series are Start Fill 3 in.

(76.2 mm) and Stop position 6 in. (152.4 mm). The LABS factory setting positions

will maintain liquid level within a distance of 2 in. (50.8 mm) from the bottom of the

operating tray on the LABS 20K, 38K, 40K, 80K units, and 3 in. (76.2 mm) from the

bottom of the operating tray on the LABS 94K.

Liquid Phase Storage

Liquid phase storage is normally utilized when liquid nitrogen temperatures are

required to maintain stored product viability and the storage medium is adequate

for storage in liquid nitrogen.

In a typical liquid phase storage system, the liquid level sensors are positioned to

maintain the liquid level at or below the top level of the inventory control system.

During operation, the upper levels of the inventory control system will at times

become exposed as the liquid level fluctuates.

Care must be taken to ensure that the liquid level remains below the bottom of the

refrigerator lid. Exposure to liquid nitrogen may result in physical damage to the lid.

Additionally, operating the refrigerator with high liquid levels characteristic of liquid

phase storage may result in turbulence during fill cycles. Caution must be exercised

if the refrigerator lid is opened during a fill, and appropriate safety equipment

should always be worn.

10

KRYOS

Comm Port

(RS-232)

Remote

Alarm

Remote Alarm:

Normal Condition............. Continuity Between pins 2 and 3

Alarm Condition................. Continuity Between pins 1 and 2

Sensor

24 VAC

Power

Solenoid

Temp 1

(Receptacle

View)

Temp 2

3

1 - Purple Wire: Normally Closed

2 - Orange Wire: Normally Open

3 - Grey Wire: Normally Open

2 1

Figure 5.0 Remote Alarm Plug Connection

Operating Parameters

When materials are immersed in liquid nitrogen, they will assume the temperature

of the liquid (-196°C/-320°F). When material is stored in the vapor phase over the

liquid, the liquid nitrogen is still a very cold refrigerant, but the refrigerator’s interior

temperature increases somewhat as product is stored higher over the liquid. This

temperature differential is not significant in many biological storage applications,

and is affected by the amount of product stored in the refrigerator, the type and size

of inventory control system, and the liquid level in the unit.

The liquid level in the refrigerator is determined by the position of the of the

Thermistor Assembly in the sensor tube. These sensors are set at installation to

maintain a specific liquid level. A filling cycle is initiated when the level falls below

the Start Fill sensor and is completed when the Stop Fill sensor is reached. This

filling cycle repeats when the level fall below the Start Fill sensor. Sensor Probe

assignments may be changed on the controller keypad to define new start and stop

levels, and these levels may be set independently to vary the liquid level differential

between fills. Prior to the initial fill of the refrigerator, a determination should be

made whether vapor phase or liquid phase storage will be utilized.

All units are supplied with a seven thermistor assembly and a freeze-guard sensor

unless otherwise specified. Factory setting positions for the K-Series are Start Fill 3 in.

(76.2 mm) and Stop position 6 in. (152.4 mm). The LABS factory setting positions

will maintain liquid level within a distance of 2 in. (50.8 mm) from the bottom of the

operating tray on the LABS 20K, 38K, 40K, 80K units, and 3 in. (76.2 mm) from the

bottom of the operating tray on the LABS 94K.

Liquid Phase Storage

Liquid phase storage is normally utilized when liquid nitrogen temperatures are

required to maintain stored product viability and the storage medium is adequate

for storage in liquid nitrogen.

In a typical liquid phase storage system, the liquid level sensors are positioned to

maintain the liquid level at or below the top level of the inventory control system.

During operation, the upper levels of the inventory control system will at times

become exposed as the liquid level fluctuates.

Care must be taken to ensure that the liquid level remains below the bottom of the

refrigerator lid. Exposure to liquid nitrogen may result in physical damage to the lid.

Additionally, operating the refrigerator with high liquid levels characteristic of liquid

phase storage may result in turbulence during fill cycles. Caution must be exercised

if the refrigerator lid is opened during a fill, and appropriate safety equipment

should always be worn.