Bio-Rad PDS-1000 / He™ and Hepta™ Systems User Manual

Page 5

The Biolistic Process

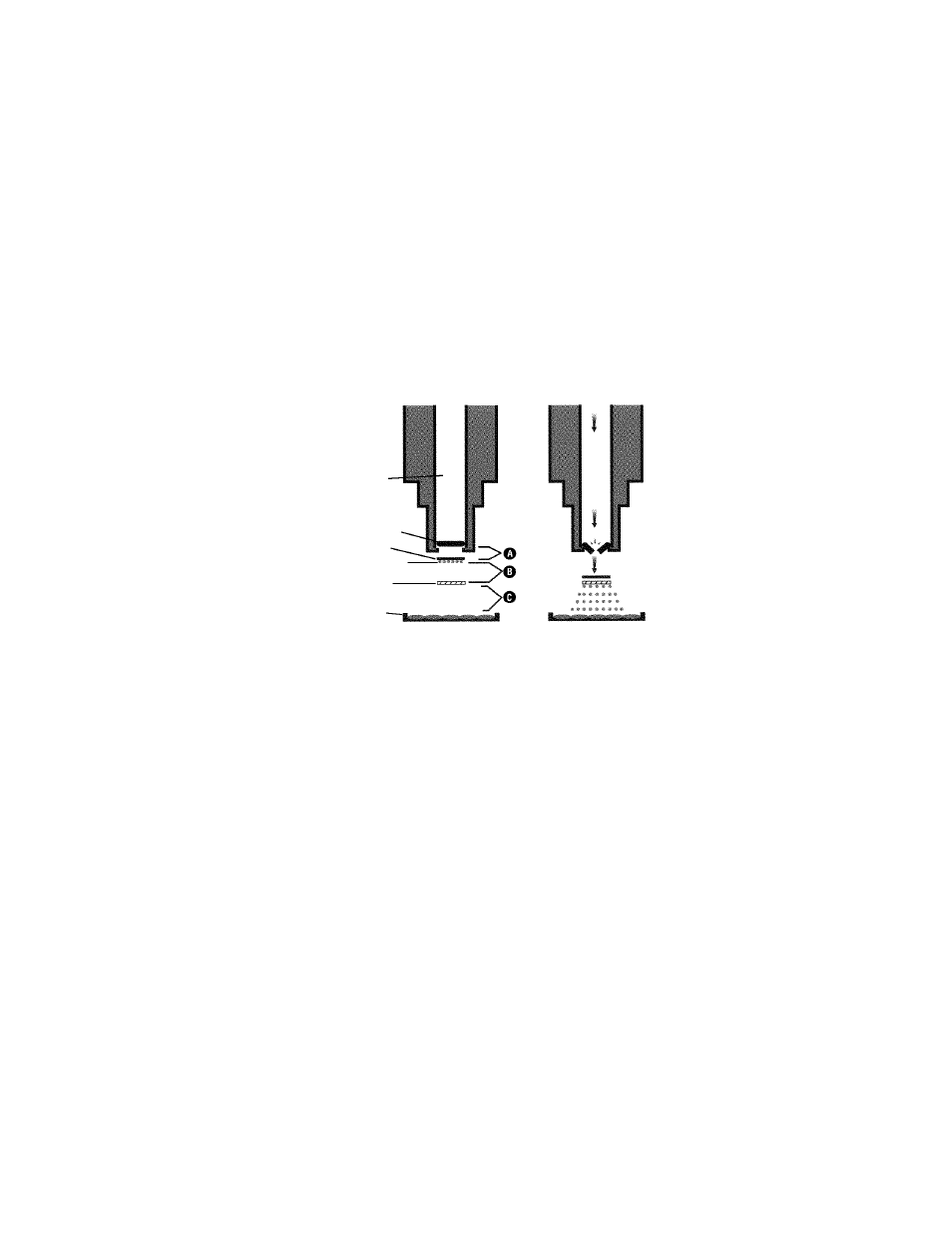

The Biolistic PDS-1000/He system uses high pressure helium, released by a rupture disk,

and partial vacuum to propel a macrocarrier sheet loaded with millions of microscopic tung-

sten or gold microcarriers toward target cells at high velocity. The microcarriers are coated with

DNA or other biological material for transformation. The macrocarrier is halted after a short

distance by a stopping screen. The DNA-coated microcarriers continue traveling toward the

target to penetrate and transform the cells.

The launch velocity of microcarriers for each bombardment is dependent upon the heli-

um pressure (rupture disk selection), the amount of vacuum in the bombardment chamber, the

distance from the rupture disk to the macrocarrier (A), the macrocarrier travel distance to the

stopping screen (B), and the distance between the stopping screen and target cells (C).

Fig. 1.2. The Biolistic bombardment process.

Design Improvements

The original Biolistic device used a gunpowder explosion to accelerate DNA-coated

microcarriers into target cells. The helium technology used in the current PDS-1000/He sys-

tem has primary advantages of providing cleaner, safer, and more reproducible particle accel-

eration. This stems from the use of rupture disks that burst at a defined pressure. In addition,

helium inflicts less tissue damage. Bulletin 1689 offers a comparative analysis of gunpowder

and helium target patterns and transformation efficiencies.

The PDS-1000/He device was updated in March 1995 to improve the quality of key com-

ponents. We removed parts originally designed to operate with the gunpowder acceleration

method. The most notable change was the conversion of the material used for the bombard-

ment chamber from metal to a strong, lightweight plastic. This makes the instrument easier

to transport and clean, with no change in bombardment performance (identical internal cham-

ber dimensions). An over-pressure relief valve and a particle filter on the vacuum vent sup-

ply were also added.

The actual steps for performing a particle bombardment of a biological sample are

unchanged, and the consumables are also the same with the plastic case version. Extensive test-

ing involving the genetic transformation of yeast, plant, and animal cells by both Bio-Rad

and independent researchers demonstrated that the gene transfer results obtained with the

new plastic chamber design are equivalent to those of the previous metal chamber model.

See Appendix 8.2 for a description of parts unique to the metal-chamber design.

2

Before

Gas Acceleration Tube

Rupture Disk

Macrocarrier

Stopping Screen

Target Cells

DNA-coated Microcarriers

After