Caution – Great Plains UT5052 Operator Manual User Manual

Page 67

Great Plains Mfg., Inc.

Section 4: Operating and Maintenance

8/9/2007

Series I UT3030-UT5052 Ultra-Till 576-026M

65

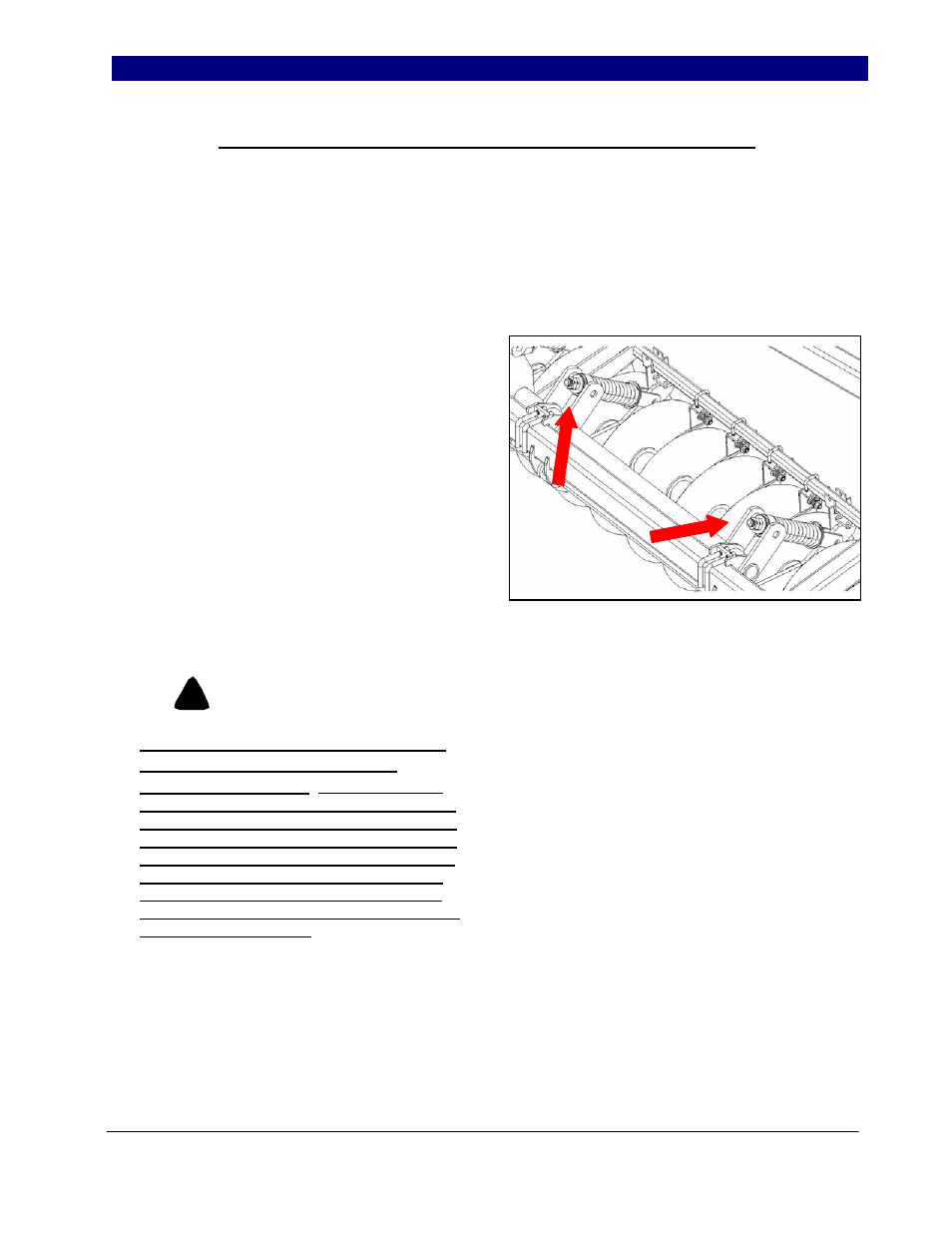

Field Adjustments & General Operation Instructions

1. The Ultra-till is designed as a primary/

secondary vertical tillage tool and is designed

to leave a finished seedbed following some

form of fall or spring tillage. In a min-till/no till

operation, it may be used as a primary one-

pass vertical tillage tool. For best results, if at

all possible, run the machine at a slight angle

to the rows. This will improve trash flow and

help spread the residue more evenly

throughout the field.

2. The ideal working speed for turbo blades is 7

to 10 MPH. If the Ultra-till is equipped with

disc-blades, then no more than 7 MPH is

recommended due to the possibility of ridging.

3. Before starting in the field: Set the depth of the

gangs at 0 inches on the gauge. Let the

machine all the way down until the cylinders

are retracted. Set your leveling front to back

with the turnbuckle on the hitch by lengthening

or shortening. Re-set the depth of gangs

between 2 to 3 on the gauge.

4. Set the hydraulic down pressure using the

instructions provided on pages 28 & 29.

5.

Caution: Never leave tractor valve

centered when unfolded with

machine in motion

. Machine damage

may occur when wings flex. The hydraulic

down pressure cylinders have no wing flex

capability and oil flow is required when the

wings flex up or down. You must have the

tractor fold hydraulic lever in continuous

downward flow or “float” position before

the wings can flex over terrain in the raised

or lowered lift position.

6. If possible, have someone observe the

machine during first time operation for

levelness – front to rear and wings to center

frame. Adjust each as needed. If ground is

soft, and the blades are running too deep,

raise the gangs to desired depth. You may

need to readjust front to back. If the ground is

hard this may raise the front and again the

front to back may need to be changed (Note:

To change front to rear, either extend to raise

the front, or shorten the turnbuckle to lower

front.) On 5-section Ultra-tills with the

hydraulic gauge wheels, set the wheels in field

position to be 1” to 2” off the ground.

7. For a final adjustment on the hydraulic down

pressure, note the action of the gang bolts as

the machine operates through the field by

watching the nuts at the top of the bolts (as

shown by arrows). If the center gang bolts are

more active than the wings, the pressure to the

wings may need to be increased. If the wing

gang bolts are cycling extensively but the

center is not, the pressure to the wings needs

to be decreased. On a five-section machine,

you need to set the outside wings with one

valve and the inside wings with the other (the

valves are marked as to which is which). Once

you have all the spring bolts across the

machine working evenly, lock the valves in

place. You may need to re-adjust these valves

as field conditions change, (i.e. ground

becomes harder as it dries out or wetter after a

rain).

8. If a basket is added for leveling, use the

eyebolt to increase or decrease down

pressure. (Note: Shorten for less pressure or

lengthen for more.)

!

CAUTION