Great Plains UT5052 Operator Manual User Manual

Page 31

Great Plains Mfg., Inc.

Section 2: Hydraulics

3/5/2008

Series I UT3030-UT5052 Ultra-Till 576-026M

29

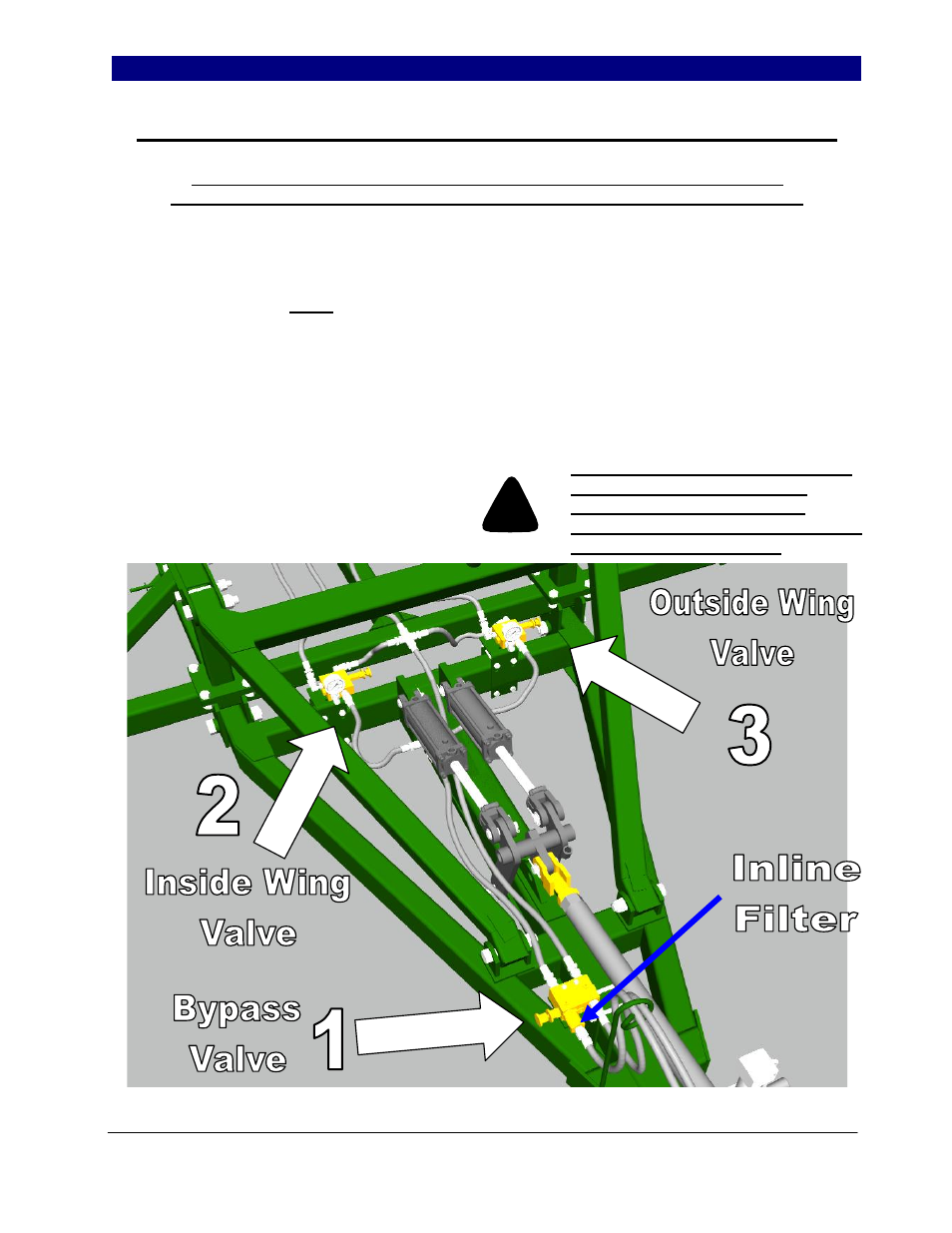

5-Section Ultra-Till Hydraulic Down Pressure Preparation and Setup

Note: This setup procedure is for tractors with closed-center or pressure

compensated flow hydraulic systems. Open center hydraulics not supported.

1. Adjust the bypass valve by turning knob

(1), Figure 2, clockwise all the way in and

then backing out 1 full turn.

2. On tractor, adjust flow-control valve to low

side of flow rate. NOTE: The faster the

flow of oil through the system the greater

potential for oil heating, premature wear

or tractor damage.

3. Lock the fold hydraulic lever for

continuous downward oil flow.

4. Adjust pressure reducing valves knob (2

& 3) on implement so the pressure

gauges reads 1200 psi each. Never

exceed 1400 psi.

5. While watching pressure gauges, slowly

open bypass valve, knob (1) until gauges

reads around 1100 psi. Pressure might rise

and then fall off as knob is opened. If

pressure exceeds 1400 psi during this step,

the tractor flow is too high, reduce tractor

flow. Lock bypass valve knob (1) at 1100 psi.

6. Finally adjust valve knobs (2 & 3) to the

desired wing down pressure setting of 400 to

700 psi. Never exceed 900 psi.

7. In field operation, Lock the fold

hydraulic lever for continuous

downward oil flow. If wings are

running too high, increase pressure

setting to the appropriate valve, knob

(2 or 3), to level machine. If center is

too high, decrease pressure setting

with knob (2) on Inside wing valve.

8.

Caution: Never leave tractor valve

centered when unfolded with

machine in motion. Machine

damage may occur when wings flex

up or down (see page 91).

Figure 2

!