Set pump adjuster, Determine orifice size, Set pump adjuster determine orifice size – Great Plains YP825AR Material Rate User Manual

Page 71

Great Plains Manufacturing, Inc.

Liquid Fertilizer Rate

67

2013-11-11

401-923B

Set Pump Adjuster

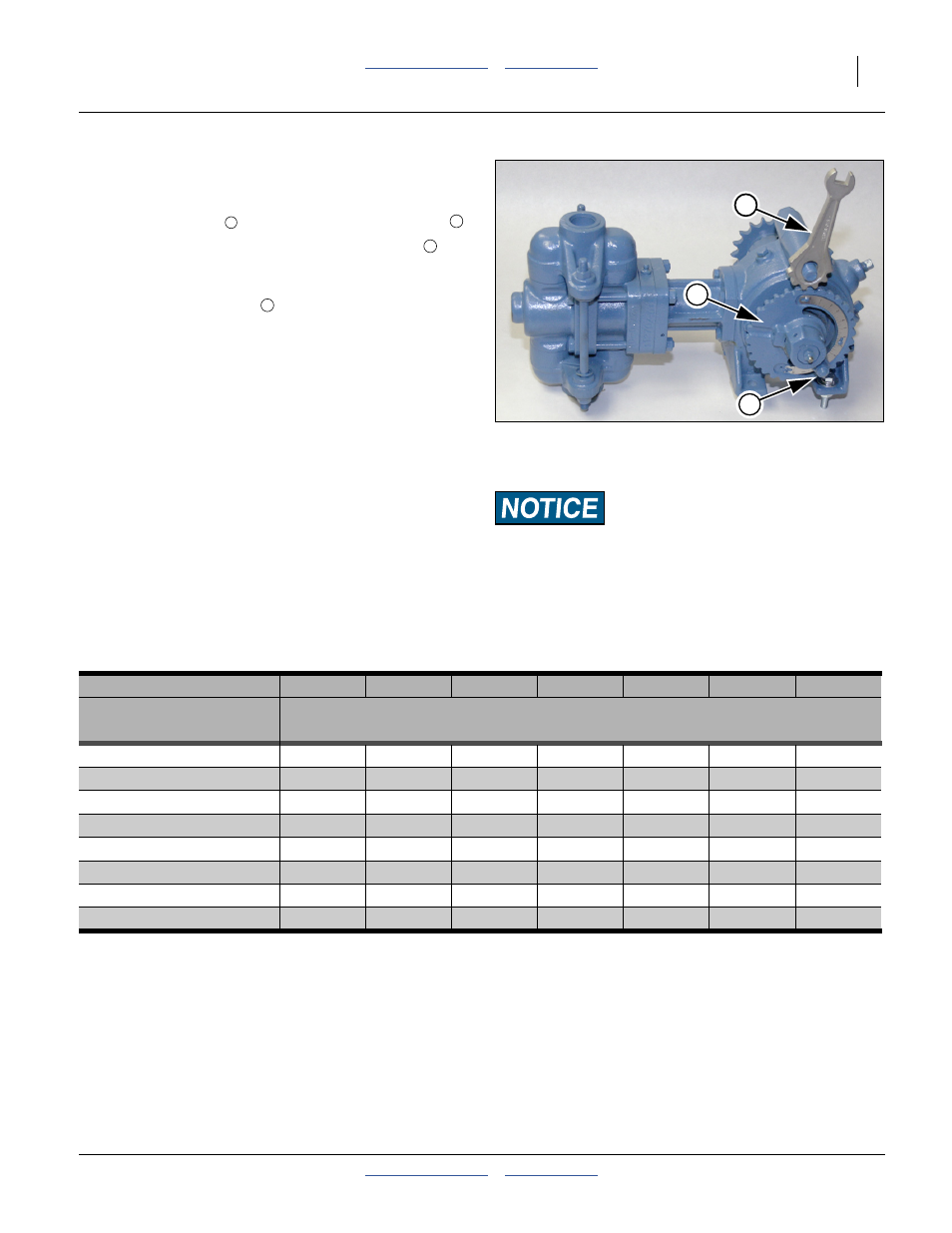

Refer to Figure 30

5.

Using the box-wrench end of the CDS-John Blue

113918-01S tool

, loosen the setting pointer nut

.

6.

Use the other end of the tool to rotate the dial

to

the setting determined by table, slide chart or

internet calculator.

7.

Re-tighten pointer nut

.

Determine Orifice Size

Orifice plates at each drop line provide back-pressure

that balances flow in the manifolds, assuring that each

row obtains the same rate. Plates are provided with the

system(s) in three sizes. Additional sizes are available.

8.

Choose orifice size based on desired rate. For a

given rate, there may be more than one orifice size

that provides the recommended back-pressure. To

reduce orifice wear, orifice plugging and pump wear,

use the largest orifice practical for your fertilizer

application rate.

The chart below shows rate ranges for each Great

Plains orifice size and row spacing. You may need to

change to the next higher or lower orifice for a

different fertilizer solution density and/or a different

ground speed.

See page 118 for a metric chart.

Note: Maximum available rate depends on pump rating, drive setup, ground speed, and planter swath.

Not all of the higher rates above are possible in all configurations.

Material Loss/Equipment Damage Risk:

Set application rate at pump, not by orifice size. Orifice size is

only used to create 15-40 psi back pressure to provide even

flow between rows. An orifice size too small causes material

loss at relief valve. A size too large can cause irregular flow.

Figure 30

LM-1255 Pump Adjuster

29980

1

2

3

1

2

3

2

Orifice Plate Size

20

28*

34*

48*

59

80

98

Recommended Rate Range in Gallons per Acre. Pressure is 15 - 40 PSI

Nozzle Spacing

(Values based on: 5.0 mph, 10.7 lbs/gallon Fertilizer solution density)

Twin Row 70 cm or 35 cm

2.4 - 4.0

4.6 - 7.5

6.9 - 11

13 - 22

20 - 33

37 - 61

58 - 95

Twin Row 75 cm

2.3 - 3.7

4.3 - 7.0

6.4 - 10

12 - 20

19 - 31

35 - 56

55 - 89

Twin Row 30 in.

2.2 - 3.6

4.2 - 6.9

6.3 - 10

12 - 20

19 - 30

34 - 56

54 - 88

22.0 in. Rows

1.5 - 1.5

2.9 - 2.9

4.3 - 4.3

8.4 - 8

13 - 13

23 - 23

37 - 37

56 cm Rows

1.5 - 1.5

2.9 - 2.9

4.3 - 4.3

8.4 - 8

13 - 13

23 - 23

36 - 36

70 cm Rows

1.2 - 2.0

2.3 - 3.7

3.4 - 5.6

6.7 - 11

10 - 17

19 - 30

29 - 48

75 cm Rows

1.1 - 1.9

2.1 - 3.5

3.2 - 5.2

6.2 - 10

9 - 15

17 - 28

27 - 45

30 in. Rows

1.1 - 1.8

2.1 - 3.4

3.2 - 5.2

6.1 - 10

9.3 - 15

17 - 28

27 - 44

* These sizes standard in most Great Plains fertilizer systems.