Great Plains YP825AR Material Rate User Manual

Page 21

Great Plains Manufacturing, Inc.

Sprocket Indexing (Stagger)

17

2013-11-11

401-923B

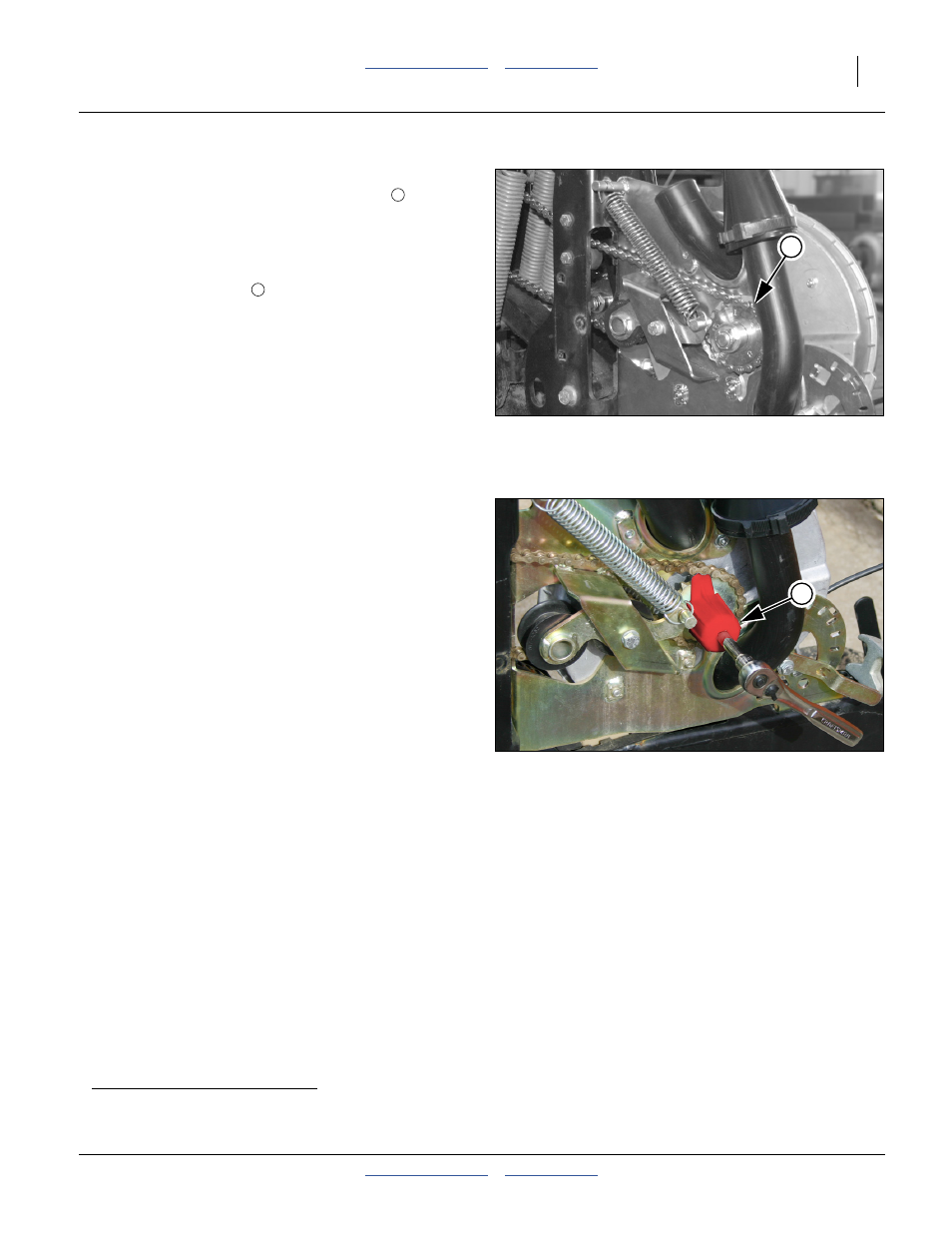

Refer to Figure 12

6.

At the rear (long mount) row unit of each pair, note

which sprocket tooth is at the index mark

. If the

sprocket is already at the chart value, skip to step 2.

Otherwise, complete step 7 through step 10 for that

row.

Refer to Figure 13

7.

Place the timing tool

over the meter shaft. Attach

a

3

⁄

8

inch socket wrench to aid in rotation.

Sweep the tool

a

tooth under the chain, rotating in the

direction opposite of that desired for sprocket

adjustment.

Each clockwise rotation of the timing tool advances

the sprocket by one tooth.

Each counter-clockwise rotation of the timing tool

retards the sprocket by one tooth.

8.

Advance or retard the sprocket until the desired tooth

number is at the index mark. Hold the sprocket

stationary, and re-mount the chain, making sure the

chain is taut in the top loop.

9.

Rotate meter shaft backward, or rotate wing drive

shaft forward to tension chain. Re-check that front

row sprocket is still at “1”.

10. Check the position of the rear row sprocket. The

tooth tip at, or just ahead of the index mark must be

the tooth called for by the chart. If not, release spring

and re-mount chain.

11. Repeat step 4 through step 10 for each row pair.

12. Re-install seed discs and meter covers. No particular

disc orientation is required during seed disc

installation. The disc is symmetrical about all four

seat lobes.

a. If the timing tool is not available, remove the idler tensioning spring to adjust the sprocket position. Rotate meter shaft backward (if

meter empty, otherwise forward one full rotation), and re-check indexing with normal tension on chain.

Figure 12

Sprocket Index Check

29628

2

2

3

Figure 13

Adjusting Sprocket Index

31444

3