Folding – Great Plains 2S-2600HDF Operator Manual v1 User Manual

Page 29

Great Plains Manufacturing, Inc.

Operating Instructions

25

2014-05-16

195-440M

Refer to Figure 22

4.

Swing the locks up and onto the transport lift

cylinders. They are temporarily held in place with

polymer bumpers. They are firmly held in place when

the cylinder is relaxed in step 5.

Note: Bumpers hold the transport lift cylinder lock chan-

nels in place temporarily. The channels will remain

in position when cylinders settle against channels.

5.

Slowly reverse the Transport Lift circuit lever until

both lock channels are resting firmly on the rod ends

of the transport lift cylinders. Set circuit lever to off.

Folding

Crushing Hazard:

Bystanders could be crushed between the folding drill boxes

and the drill tongue. To avoid serious injury or death, keep all

bystanders well away during folding operation.

1.

Park tractor and drill on level ground with tractor

transmission in Park. Be aware of clearance needed

to fold drill.

2.

Fold up markers if installed. See “Marker

Operation” on page 40. Return selector valve

handle to Fold position.

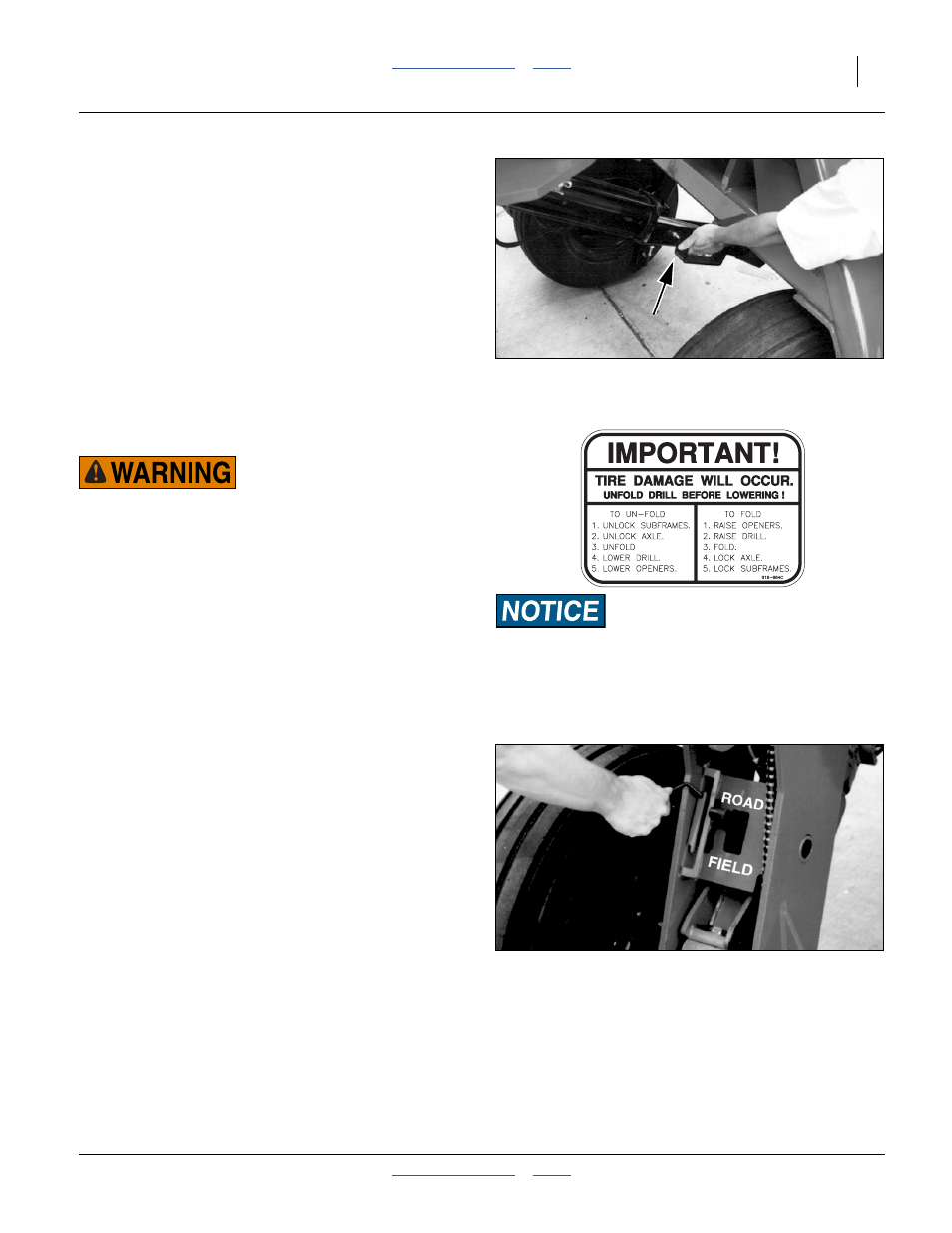

Refer to Figure 23

3.

Raise openers. Opener subframe must be raised for

folding. Position all six opener lock handles in ROAD

position and completely raise openers. See “Raising

and Lowering Openers” on page 23.

Note: The opener transport lock handles are spring load-

ed and can be moved to ROAD position with open-

ers up or down, but locks only engage when

openers are completely raised. There are two locks

on each drill section.

4.

Raise drill, engage lift lock channels and allow drill to

settle on lock channels. See “Raising Drill

(Transport Lift)” on page 24.

Note: During transport lift, wings flex down before lifting

off ground.

Figure 22

Transport Lift Cylinder Lock

15552

Machine Damage Risk:

Both Opener and Transport Lift circuits must be raised and

locked up before folding, or implement damage will result.

Figure 23 - Fold

Opener Lock Up

15549