Adjusting gauge wheel scrapers – Great Plains 2525A Operator Manual User Manual

Page 49

Great Plains Manufacturing, Inc.

Adjustments

45

2013-06-04

118-999M

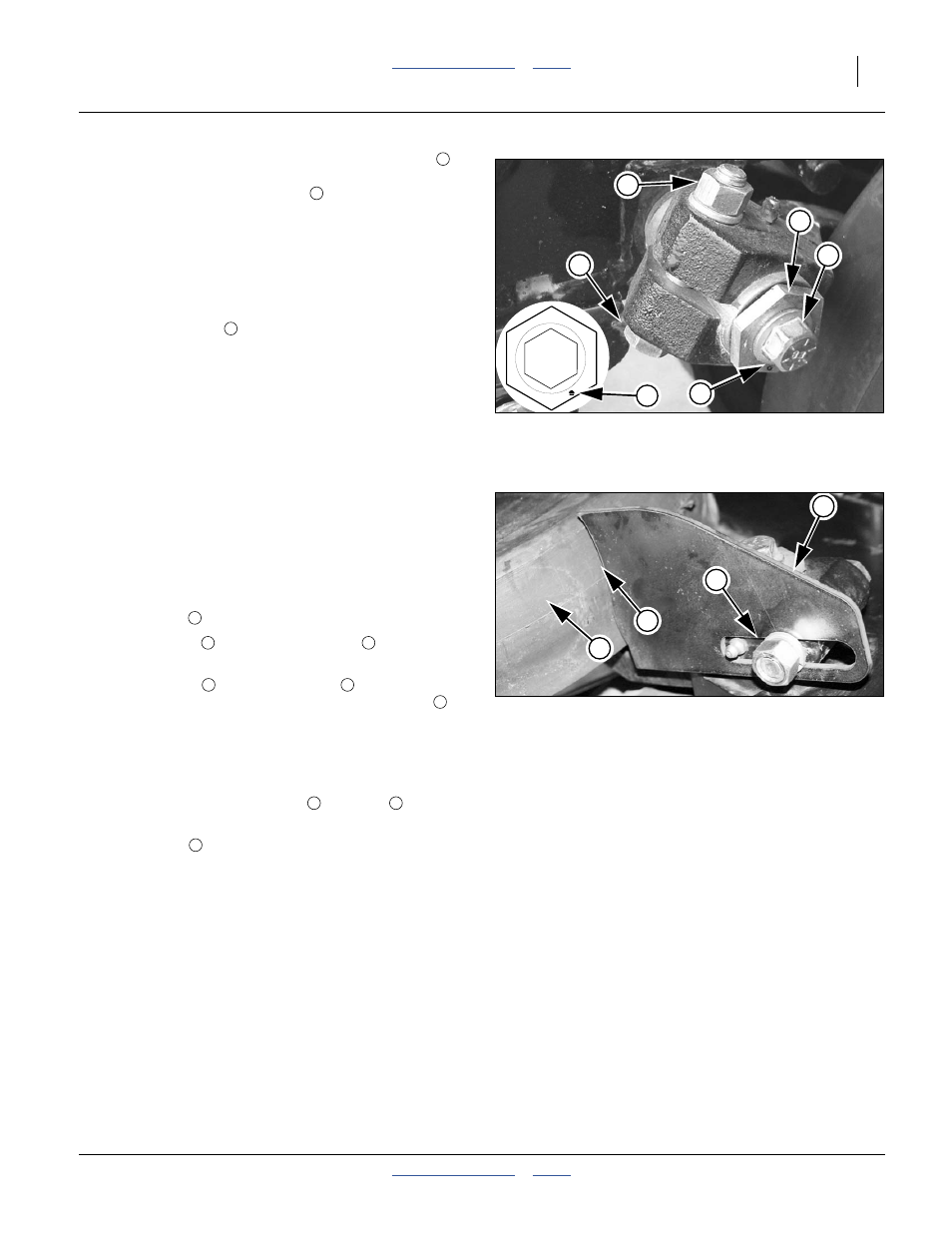

• If wheel does not fall freely, loosen hex-head bolt

and slide wheel arm out just until wheel and arm move

freely. Retighten hex-head bolt

according to grade:

1

⁄

2

in Grade 5 bolt, 75 ft-lbs (102 N-m).

1

⁄

2

in Grade 8 bolt, 110 ft-lbs (149 N-m).

Note: Use “Torque Values Chart” on page 90 for refer-

ence.

6.

Keep turning hex adjuster and moving wheel arm

until the wheel is adjusted properly. When satisfied,

tighten pivot bolt

to 110 ft-lbs (149 N-m).

Adjusting Gauge Wheel Scrapers

Refer to Figure 42 (depicting a bottom view)

Scrapers are optional, and may be useful in moist or

sticky soils that tend to accumulate on gauge wheels and

reduce intended planting depth.

To adjust scrapers:

1.

Loosen nut

.

2.

Slide scraper

toward gauge wheel

until scraper

touches tire.

3.

Slide scraper

away from wheel

leaving a

⁄

.

4.

Rotate scraper left and right around bolt, making

sure it cannot touch tire if bumped in field. If it can

touch tire, back scraper away from wheel until it can-

not.

5.

Center scraper angle on bolt

until gap

is con-

stant.

6.

Tighten nut

.

Starting Point

Figure 41

Disk/Gauge Wheel Adjustment

22524

22525

2

2

1

4

4

1

1

1

2

Figure 42

Gauge Wheel Scraper

25273

8

5

6

7

5

6

8

6

8

7

5

7

5