Fan circuit operation – Great Plains 2525A Operator Manual User Manual

Page 28

24

2025A/2525A

Great Plains Manufacturing, Inc.

118-999M

2013-06-04

Fan Circuit Operation

See also “Fan and Adjustment” on page 35.

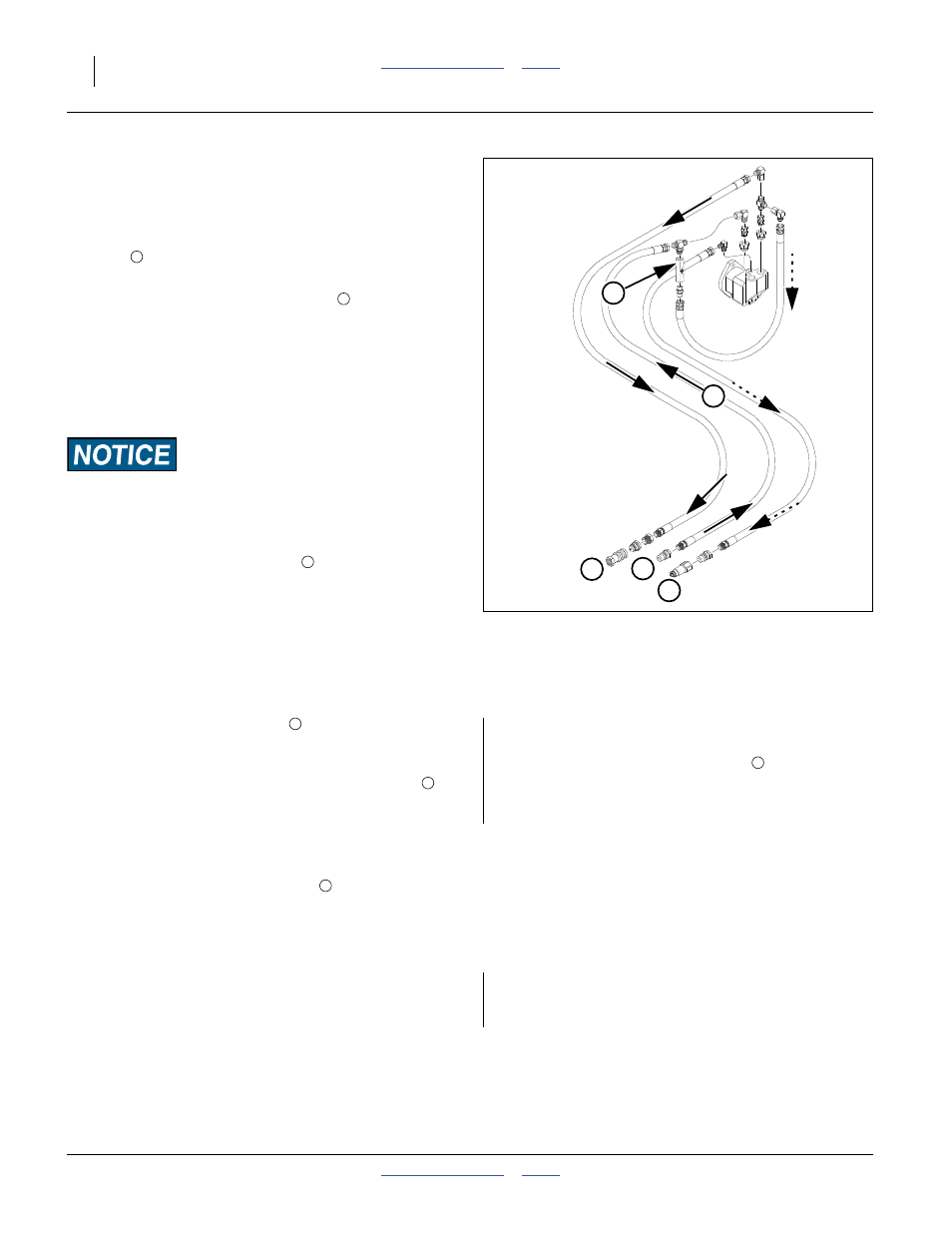

Refer to Figure 13

Three hydraulic hoses serve the fan, and must be prop-

erly connected for the fan to operate in the correct

direction

, at recommended speeds, and without dam-

age. See “Hydraulic Hose Hookup” on page 14.

1.

Always connect the case drain line

first.

This line protects the outer shaft seal of the hydraulic

motor. The case drain is a small line to the hitch, pro-

visioned with a specialized low-seep flat-face case

drain Quick Disconnect. Pressure spikes during

motor operation, and pressure cycles due to temper-

ature change are bled off by the case drain.

Motor Seal Damage Hazard

Do not apply pressure to the case drain line. Do not change the

special QD connector. A restricted or sealed case drain line

will promptly result in motor seal damage.

2.

Connect the motor return line

second, to sump.

The drill includes a 1

⁄

tor>16in low back-pressure QD coupler set. Install 3. Connect the motor inlet line to a tractor remote capable of 4.5 gallons/minute. If a priority remote is 4. The fan hydraulic circuit includes a check valve , which provides a relief path for oil at motor shutoff. Correct fan direction is shown at . If reversed fan is suspected, observe it during shutoff, as the direction Fan speed is controlled by the tractor circuit and butterfly You may stop the fan by setting the circuit to neutral or Figure 13 Hydraulics at Fan 29781 1 2 3 4 5 1 2 3 If the fan is connected in reverse, it may not run at all prevents the fan from reaching high rpm. A reversed fan may send 5 4 5 1 Fan speed can change as oil heats to operating temper-

the receptacle on a tractor sump port, and not at a

normal remote return port. The unusual size aids in

ensuring correct connection, so that the motor return

line handles high volume at low back-pressure,

ensuring full motor performance.

available, use it for the fan.

If the fan is connected in reverse, flow through this

valve results in low fan rpm provides strong indica-

tion reversed connection.

of motion is easier to see at lower rpms as it slows to

a stop (initial startup is virtually instantaneous, mak-

ing observation at start difficult).

valve (and not the seed monitor).

float. The check valve slows the blades to a stop by

locally recirculating the oil.

(due to no oil source at the return connection). If oil is

present, oil bypass at the check valve

some air to the meters, but is incapable of providing reli-

able air flow for planting.

ature. Re-check meter pressure more often during early

operations.