Great Plains NP3000A Operator Manual User Manual

Page 103

Great Plains Manufacturing, Inc.

Troubleshooting

99

2014-04-22

407-613M

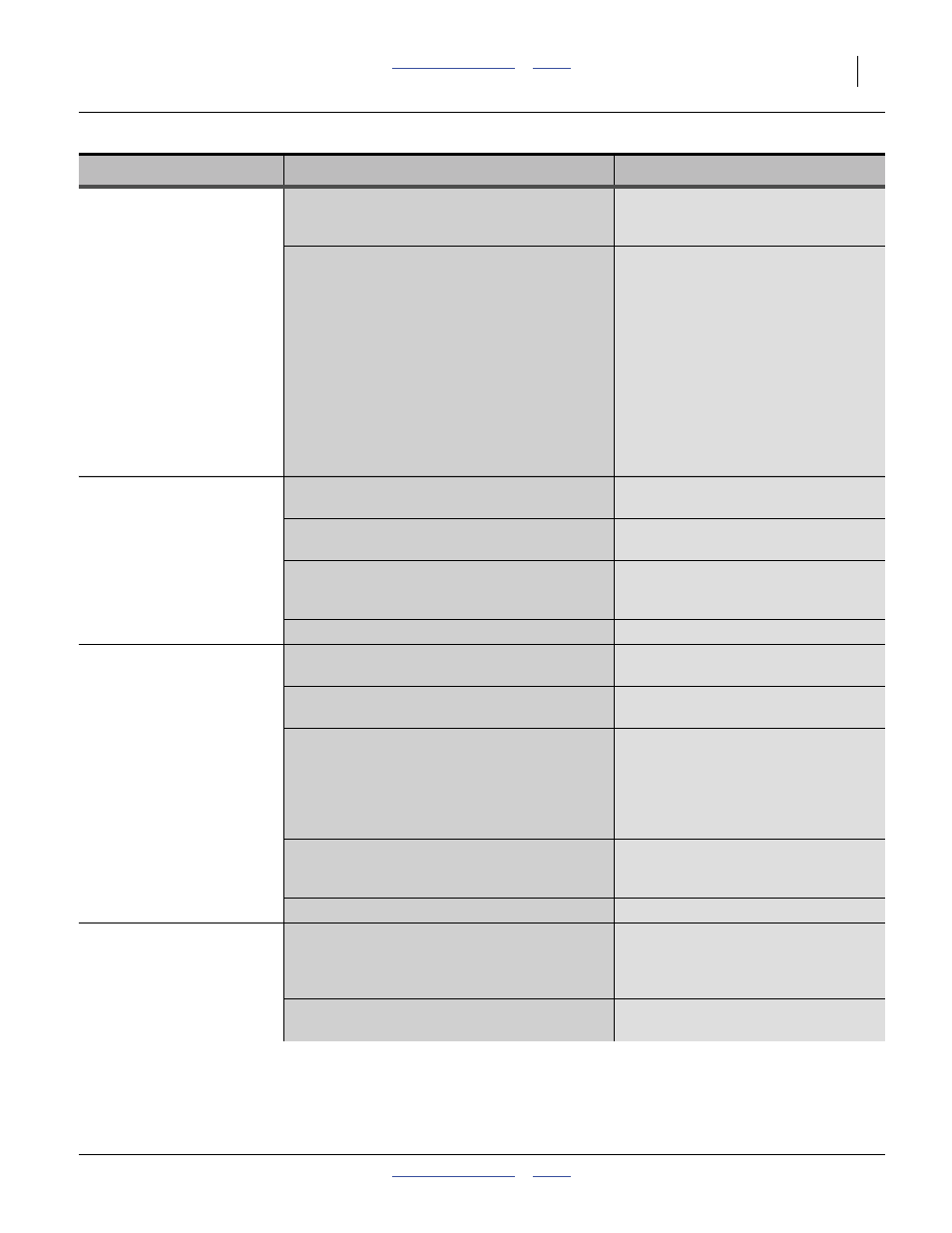

Rate Alarm, High

Incorrect VALVE CAL for Control Valve or

METER CAL for flow meter.

Recheck console setup against

values provided for components

(page 44).

Control Valve failed, or harness status

Suspend operation (page 63).

Close emergency shut-off valve.

Discharge line from emergency

shut-off valve to tines.

Wait for applicator to be safe to

approach.

Check harness connections and

fuses.

Use console SELF-TEST mode to

command rate to zero open. Check

valve ball indicators at valves.

Command rate to maximum. Check

ball indicator.

Excess NH

3

Remaining

(but no alarms)

Incorrect console setup

Re-check METER CAL and BOOM

CAL.

Field size different.

After ruling out metering problems,

re-check geography.

Excessive gaps between fertilizer applicator

passes.

Gap between opposing pass end

trenches should be one row space

(e.g. 30in)

Flow meter malfunction

Consult dealer.

NH

3

Consumption Too

High (but no alarms)

Incorrect console setup

Re-check METER CAL and BOOM

CAL.

Field size different.

After ruling out metering problems,

re-check geography.

Excessive overlap

Gap between opposing pass end

trenches should be one row space

(e.g. 30in). Also check tracks for

unintended re-applications,

particularly if relying on GPS

mapping.

Tank or system Leak

Suspend application. Carefully

approach applicator and nurse tank

from up-wind. Check for leaks in

Flow meter malfunction

Consult dealer.

Rows Not Fertilized

Check for plugged row-unit tube

Stop application per page 64. Lift

applicator and inspect tines. Clear

any plugging per “Clearing Plugged

Tines” on page 110.

Failed or malfunctioning aftermarket section

control.

Consult system supplier

documentation.

Problem

Cause

Solution