Adjustments, Side gauge wheels – Great Plains 1525P Operator Manual User Manual

Page 26

1525P, 1510HDP

118-949M

8/14/2006

24

Side Gauge Wheels

Refer to Figure 10

The side gauge wheels have two, interrelated adjustments:

• angle of side gauge wheel, and

• distance between side gauge wheel and row unit disk.

Refer to Figure 11

Adjust side-gauge-wheel angle so the wheels contact the

row unit disks at the bottom of wheel at 2” planting depth.

At the same time, keep the side gauge wheels close to the

opener disks so openers do not plug with soil or trash but far

enough out so the disks and wheels turn freely.

• If contact point is between 4 to 8 o’clock but dis-

tance to tire is not correct, then add or remove shims

as needed. DO NOT ADJUST BEARING AS THAT

WILL ADJUST WHEEL-TO-DISK CONTACT AREA

ONLY.

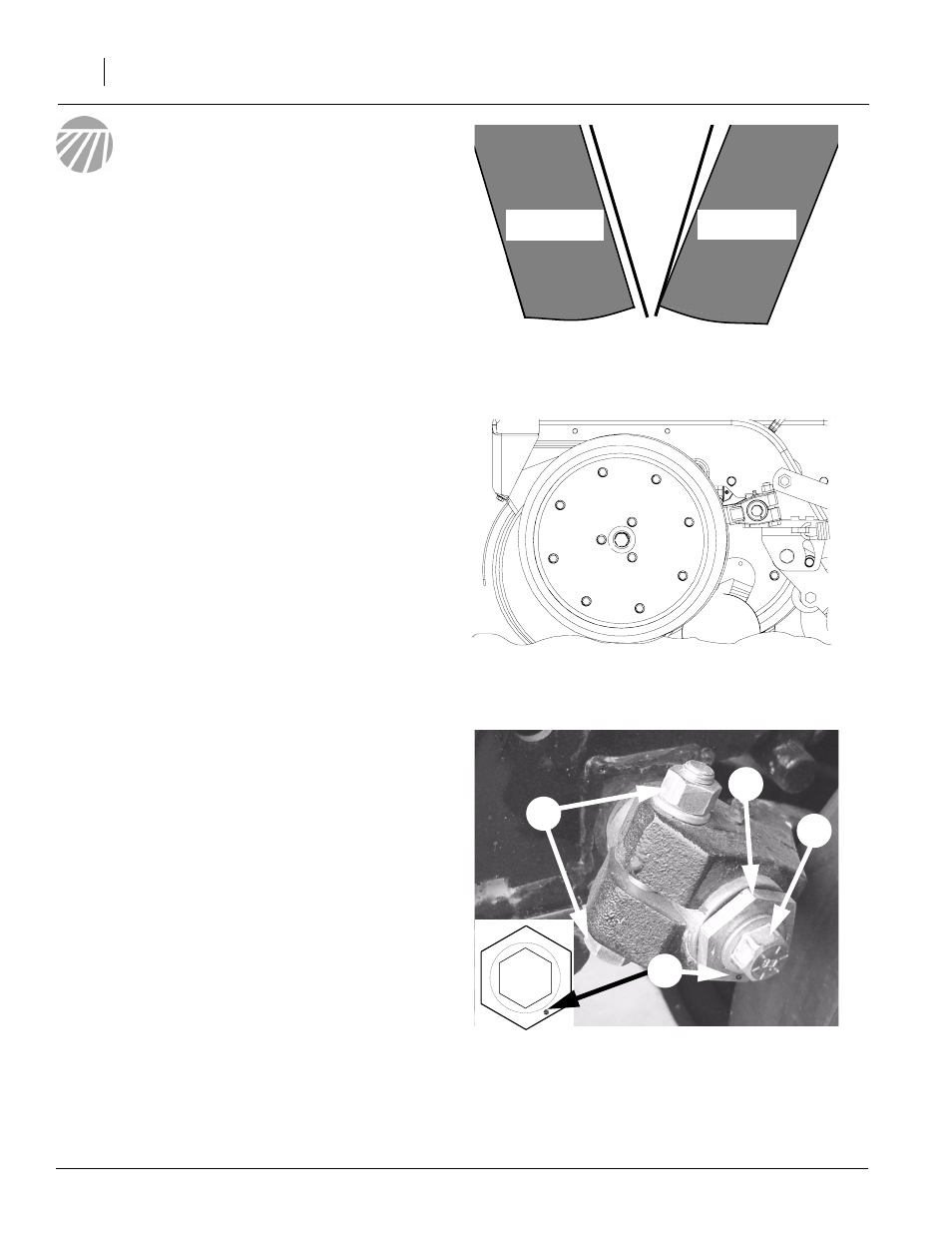

Refer to Figure 12

To adjust Wheel-to-Disk contact area of side gauge wheels:

1.

Raise drill slightly to remove weight from side gauge

wheels.

2.

Loosen hex-head bolt (1). Move wheel and arm out on o-

ring bushing.

3.

Loosen pivot bolt (2). Turn hex adjuster (3) so indicator

notch (4) is at 5 o’clock to 7 o’clock. Use this as the start-

ing point for adjustment.

4.

Move wheel arm in so side gauge wheel contacts row

unit disk. Tighten hex-head bolt (1) to clamp arm around

bushing and shank.

5.

Check the wheel-to-disk contact at 2” planting depth. Lift

wheel and arm. When let go, the wheel should fall freely.

• If wheel does not contact disk at bottom to area

where blade leaves contact with soil, move hex ad-

juster until wheel is angled for proper contact with disk.

• If wheel does not fall freely, loosen hex-head bolt (1)

and slide wheel arm out just until wheel and arm move

freely. Retighten hex-head bolt (1) according to grade:

• 1/2” Gr 5 bolt on 25 series, 75 ft-lbs.

• 1/2” Gr 8 bolt on 25 series, 110 ft-lbs.

NOTE: Use “Torque Values Chart”, on page 141 for ref-

erence.

Side Gauge

Wheel

Side Gauge

Wheel

Opener

Disks

Incorrect

Correct

Figure 10

Side Gauge Wheels

22531

Figure 11

Wheel-to-Disk Contact Area

Figure 12

Side Gauge Wheel Adjustment

Starting Point

22525

2

1

3

4

Adjustments

6.

Keep turning hex adjuster and moving wheel arm

until the wheel is adjusted properly. When satisfied,

tighten pivot bolt (2) to 110 foot-pounds.