Carrier DOWNFLOW HORIZONTAL 2-SPEED User Manual

Page 2

ELECTROSTATIC DISCHARGE (ESD) PRECAUTIONS

PROCEDURE

Electrostatic discharge can affect electronic components.

Take precautions during furnace installation and servicing to

protect the furnace electronic control. Precautions will pre-

vent electrostatic discharges from personnel and hand tools

which are held during the procedure. These precautions will

help to avoid exposing the control to electrostatic discharge

by putting the furnace, the control, and the person at the same

electrostatic potential.

1. Disconnect all power to the furnace. DO NOT TOUCH THE

CONTROL OR ANY WIRE CONNECTED TO THE CON-

TROL PRIOR TO DISCHARGING YOUR BODY’S ELEC-

TROSTATIC CHARGE TO GROUND.

2. Firmly touch a clean, unpainted, metal surface of the furnace

chassis which is close to the control. Tools held in a person’s

hand during grounding will be satisfactorily discharged.

3. After touching the chassis you may proceed to service the

control or connecting wires as long as you do nothing that

recharges your body with static electricity (for example; DO

NOT move or shuffle your feet, DO NOT touch ungrounded

objects, etc.).

4. If you touch ungrounded objects (recharge your body with

static electricity), firmly touch furnace again before touching

control or wires.

5. Use this procedure for installed and uninstalled (ungrounded)

furnaces.

6. Before removing a new control from its container, discharge

your body’s electrostatic charge to ground to protect the

control from damage. If the control is to be installed in a

furnace, follow items 1 through 5 before bringing the control

or yourself into contact with the furnace. Put all used AND

new controls into containers before touching ungrounded

objects.

7. An ESD service kit (available from commercial sources) may

also be used to prevent ESD damage.

INTRODUCTION

The model 58TMA Series 111 Furnace is available in sizes 65,000

through 123,000 Btuh input capacities.

The design of the downflow/horizontal gas-fired furnace is

A.G.A./C.G.A. certified for natural and propane gases and for

installation on noncombustible flooring. The furnace is factory-

shipped for use with natural gas. The manufacturer’s accessory gas

conversion kit is required to convert furnace for use with propane

gas.

These furnaces SHALL NOT be installed directly on carpeting,

tile, or any other combustible material other than wood flooring. In

downflow installations, the manufacturer’s accessory floor base

must be used when installed on combustible materials and wood

flooring. Special base is not required when this furnace is installed

on manufacturer’s Coil Assembly Part No. CD5 or CK5, or when

Coil Box Part No. KCAKC is used. This furnace is for installation

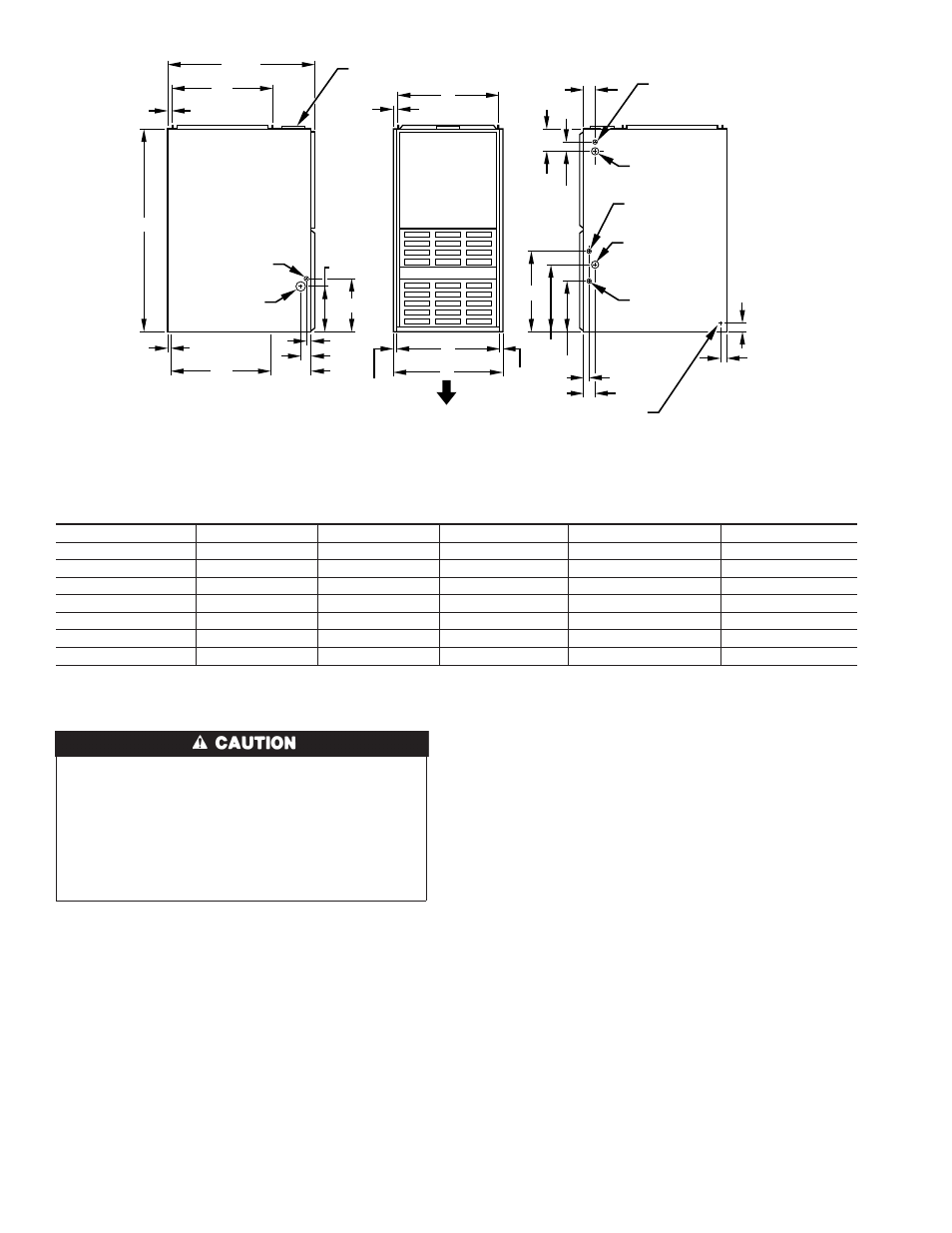

Fig. 1—Dimensional Drawing

A88324

4

3

⁄

16

″

2″

2

15

⁄

16

″

13

⁄

16

″

11

⁄

16

″

9

1

⁄

8

″

10

1

⁄

4

″

1

1

⁄

16

″

2

1

⁄

8

″

8

1

⁄

4

″

10

1

⁄

4

″

1

1

⁄

16

″

2

1

⁄

8

″

16

1

⁄

16

″

13

5

⁄

16

″

19″

11

⁄

16

″

13

⁄

16

″

11

⁄

16

″

20″

28

1

⁄

2

″

39

7

⁄

8

″

D

5

⁄

8

″ TYP

1″ TYP

E

A

AIRFLOW

OUTLET

INLET

1

⁄

2

″ DIA

THERMOSTAT

WIRE ENTRY

7

⁄

8

″ DIA

ACCESSORY

7

⁄

8

″ DIA

ACCESSORY

DIMPLES TO DRILL HOLES

FOR HANGER BOLTS (4 PLACES)

IN HORIZONTAL POSITION

ADDITIONAL

7

⁄

8

″ DIA K.O. ARE

LOCATED IN THE TOP PLATE

AND BOTTOM PLATE

NOTE:

7

⁄

8

″ DIA HOLE

POWER ENTRY

1

1

⁄

2

″ DIA

R.H. GAS ENTRY

7

⁄

8

″ DIA

ACCESSORY

1

3

⁄

4

″ DIA HOLE

GAS ENTRY

VENT CONNECTION

Table 1—Dimensions (In.)

UNIT SIZE

A

D

E

VENT CONN

SHIP. WT

065-08

14-3/16

12-9/16

12-11/16

4

141

065-12

14-3/16

12-9/16

12-11/16

4

145

085-12

17-1/2

15-7/8

16

4

154

085-16

17-1/2

15-7/8

16

4

154

105-16

17-1/2

15-7/8

16

4

171

105-20

21

19-3/8

19-1/2

4

181

125-20

24-1/2

22-7/8

23

5

192

2

→