Table 8—blower off delay setup switch position – Carrier DOWNFLOW HORIZONTAL 2-SPEED User Manual

Page 12

his furnace is equipped with 2 manual reset limit switches in

gas control area. The switches will open and shut off power

to gas valve if a flame rollout or an overheating condition

occurs in gas control area. DO NOT bypass switches. Correct

inadequate combustion air supply, component failure, re-

stricted flue gas passageway before resetting switches.

SEQUENCE OF OPERATION

Using the schematic diagram follow sequence of operation through

different modes. (See Fig. 18.) Read and follow wiring diagram

very carefully.

NOTE: If power interruption occurs during "call for heat" (W/W1

or W/W1-and-W2), control starts 90-sec blower only on period 2

sec after power is restored if thermostat is still calling for gas

heating. The red LED flashes code 12 during 90-sec period, after

which LED will be on continuously as long as no faults are

detected. After 90-sec period, furnace responds to thermostat

normally.

Blower door must be installed for power to be conducted through

blower door interlock switch ILK to furnace control CPU, trans-

former TRAN, inducer motor IDM, blower motor BLWM, hot

surface ignitor HSI, and gas valve GV.

1. Adaptive Heating Mode—Single-Stage Thermostat and

2-Stage Heating

(See Fig. 16 for thermostat connections.)

NOTE: With high-heat-only switch SW-1 off, low-heat-only

switch SW-2 selects either low-heat-only operation mode when on

(see item 2. below), or adaptive heating mode when off in response

to "call for heat." (See Fig. 17.) When high-heat-only switch SW-1

is on, it always causes high-gas-heat operation when R-W/W1

circuit is closed, regardless of the setting of low-heat-only switch

SW-2.

This furnace can operate as a 2-stage furnace with a single-

stage thermostat because furnace control CPU includes a

programmed adaptive sequence of controlled operation which

selects low-gas-heat or high-gas-heat operation. This selection

is based upon stored history of the length of previous gas

heating on/off periods of single-stage thermostat.

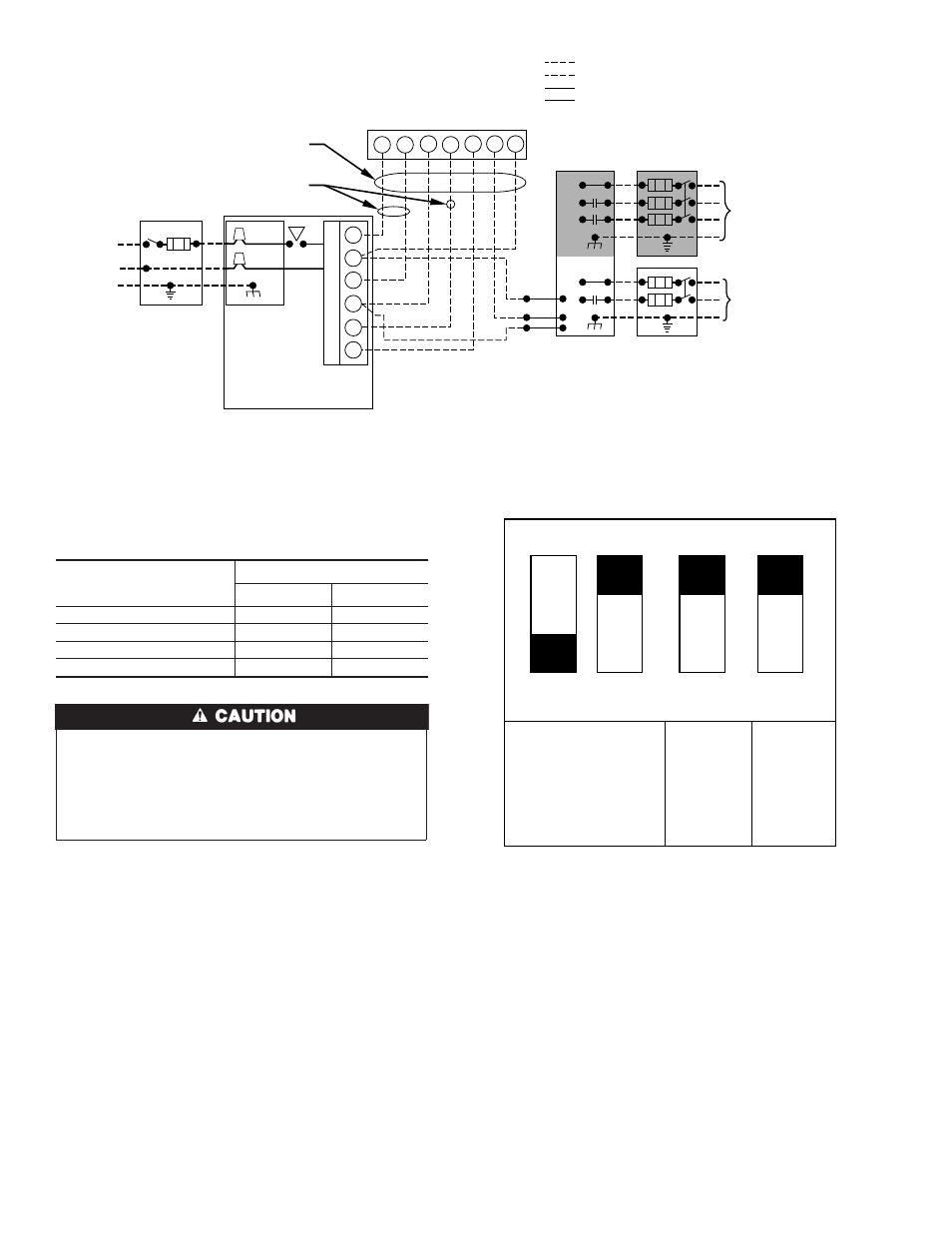

→ Fig. 16—Heating and Cooling Application Diagram With 2-Stage Thermostat and Condensing Unit

A97444

115-V FUSED

DISCONNECT

SWITCH

(WHEN REQUIRED)

JUNCTION

BOX

CONTROL

BOX

24-V

TERMINAL

BLOCK

THREE-WIRE

HEATING-

ONLY

SEVEN

WIRE

2-STAGE THERMOSTAT TERMINALS

FIELD-SUPPLIED

FUSED DISCONNECT

2-SPEED

CONDENSING

UNIT

FURNACE

G

R

W2

Y2

G

Y1

C

GND

GND

FIELD 24-V WIRING

FIELD 115-, 208/230-, 460-V WIRING

FACTORY 24-V WIRING

FACTORY 115-V WIRING

208/230- OR

460-V

THREE

PHASE

208/230-V

SINGLE

PHASE

Y2

Y1

C

WHT

BLK

WHT

BLK

W1

R

W2

COM

W/W1

Y/Y2

NOTES:

1. Connect Y-terminal as shown for proper operation.

2. Some thermostats require a "C" terminal connection as shown.

3. If any of the original wire, as supplied, must be replaced,

use same type or equivalent wire.

Table 8—Blower Off Delay Setup Switch

Position

DESIRED HEATING

MODE BLOWER OFF

DELAY (SEC)

SETUP SWITCH

SW-3

SW-4

90

OFF

OFF

135

OFF

ON

180

ON

OFF

225

ON

ON

→ Fig. 17—Setup Switches on Control Center

(Factory Settings)

A96402

BLOWER-

OFF

DELAY

LOW

HEAT

(ADAPTIVE

ALGORITHM)

HIGH

HEAT

ONLY

4

3

2

OFF

ON

1

12