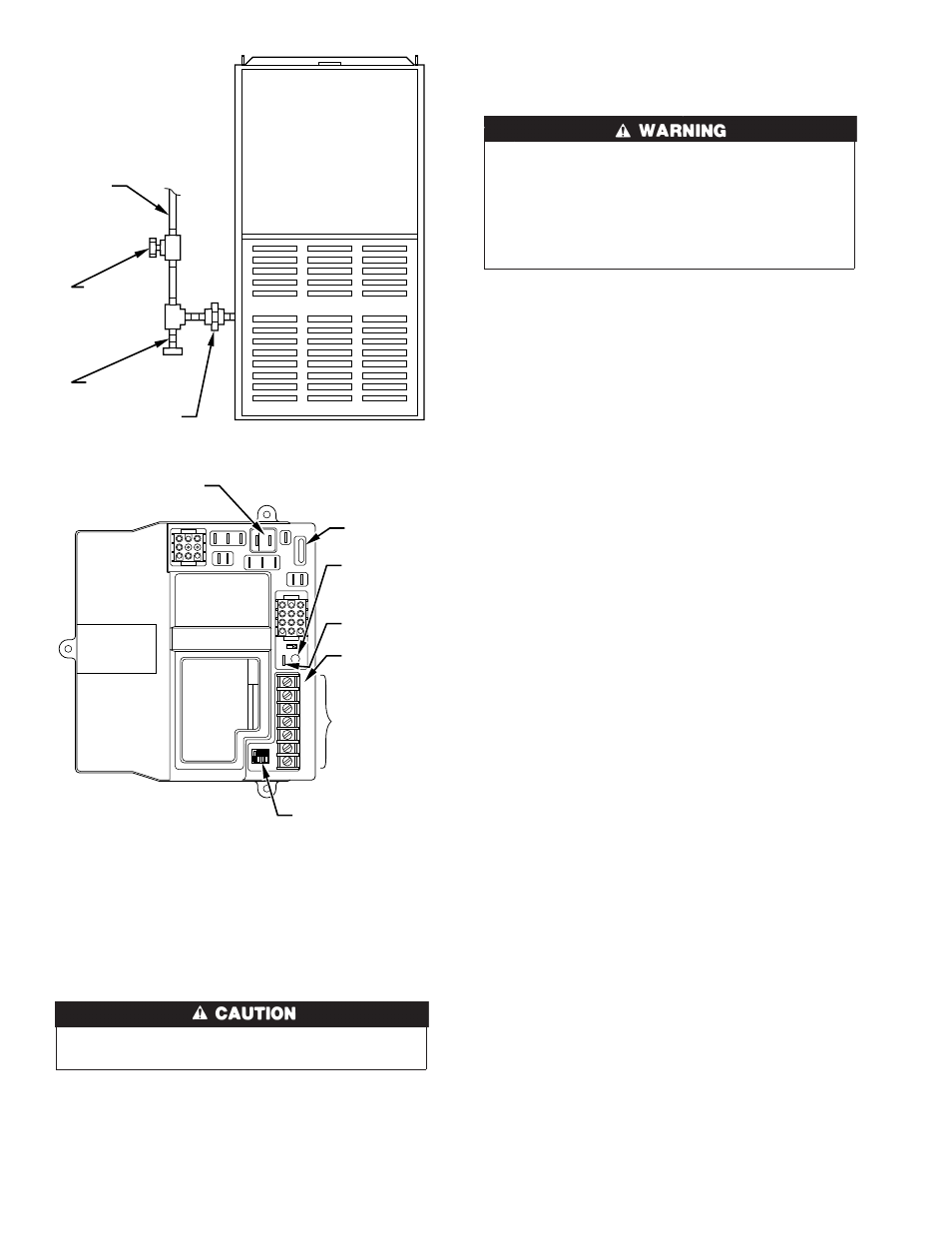

Fig. 13—typical gas pipe arrangement, Fig. 14—control center – Carrier DOWNFLOW HORIZONTAL 2-SPEED User Manual

Page 10

Step 8—Electrical Connections

115-V WIRING

Refer to unit rating plate or Table 6 for equipment electrical

requirements. The control system requires an earth ground for

proper operation.

Do not connect aluminum wire between disconnect switch

and furnace. Use only copper wire.

Make all electrical connections in accordance with the current

edition of the National Electrical Code (NEC) ANSI/NFPA

70-1996 and any local codes or ordinances that might apply. For

Canadian installations, all electrical connections must be made in

accordance with CSA C22.1 Canadian Electrical Code or authori-

ties having jurisdiction.

NOTE: Proper polarity must be maintained for 115-v wiring. If

polarity is incorrect, the furnace control status LED will flash

rapidly and prevent heating operation.

The cabinet must have an uninterrupted or unbroken ground

according to NEC ANSI/NFPA 70-1996 and Canadian Elec-

trical Code CSA C22.1 or local codes to minimize personal

injury if an electrical fault should occur. This may consist of

electrical wire or conduit approved for electrical ground when

installed in accordance with existing electrical codes. Do not

use gas piping as an electrical ground.

24-V WIRING

Refer to ESD Precautions Procedure before proceeding with 24-v

connections.

Make field 24-v connections at the 24-v terminal block. (See Fig.

14.) Connect terminal Y/Y2 as shown in Fig. 15 or 16 for proper

operation in cooling mode. Use AWG No. 18 color-coded, copper

thermostat wire only.

When furnace is installed in horizontal position with RH discharge

air, 24-v wire connections can be made easier by removing the 2

control box mounting screws and letting control box turn so that

24-v screw terminals are visible. Be sure to reinstall control box

after connections are made.

The 24-v circuit contains an automotive-type, 3-amp fuse located

on main control. Any 24-v electrical shorts during installation,

service, or maintenance could cause this fuse to blow. If fuse

replacement is required, use ONLY a 3-amp fuse. The control will

flash code 24 when fuse needs replacement.

ACCESSORIES

1. Electronic air cleaner (EAC)

A terminal block (EAC-1 [hot] and EAC-2 [neutral]) is

provided for EAC connection. (See Fig. 14.) The terminals are

energized with 115v, 1-amp maximum during blower motor

operation.

2. Humidifier (HUM)

Screw terminals (HUM-1 and C

OM

) are provided for 24-v

humidifier connection. The terminals are energized with 24v,

0.5-amp maximum when the gas valve is energized.

Step 9—VENTING

Refer to National or Local Installation Code such as; National Fuel

Gas Code NFPA No. 54-1996/Z223.1-1996, or the Canadian

Installation Code, CAN B149.1- and .2-M95, for proper vent

sizing and installation requirements. Use enclosed Venting Tables

for Category I Fan-Assisted Furnaces for quick, easy reference.

The horizontal portion of the venting system shall maintain a

minimum of 1/4-in. upward slope per linear ft, and it shall be

rigidly supported every 5 ft or less with hangers or straps to ensure

that there will be no movement after installation.

Step 10—Start-Up, Adjustment, and Safety Check

GENERAL

The furnace must have a 115-v power supply properly connected

and grounded. Correct polarity must be maintained to enable gas

heating operation.

The gas service pressure must not exceed 0.5 psig (14-in. wc), and

be no less than 0.16 psig (4.5-in. wc).

Thermostat wire connections at R and W/W1 are the minimum

required for gas heating operation. W2 must be connected for

2-stage heating thermostats. C

OM

, Y/Y2, and G are required for

cooling, heat pumps, and some clock thermostats. These must be

made at 24-v terminal block on control. (See Fig. 14.)

Fig. 13—Typical Gas Pipe Arrangement

A89414

GAS

SUPPLY

MANUAL

SHUTOFF

VALVE

(REQUIRED)

SEDIMENT

TRAP

UNION

Fig. 14—Control Center

A93348

1

2

3

4

5

6

7

8

9

PR2

L2

COM

PR1

L1

EAC-2

EAC-1

H

I-COO

L

HI-GAS -HEAT

LO-GAS -HEAT

PARK

3

FU1

SEC-1

SEC-2

1

1

2

3

4

5

6

7

8

9

10 11

12

MASTER SLAVE

TWIN TEST

LED

G

R

Y/Y2

W/W1

COM 24 V

W2

1

ON

OFF

12

34

FURNACE AND

BLOWER OFF DELAY

SETUP SWITCHES

24-VOLT

THERMOSTAT

TERMINALS

EAC - ELECTRONIC

AIR CLEANER

(115-VAC 1 AMP MAX)

3-AMP

FUSE

LED -

DIAGNOSTIC

LIGHT

TWIN / TEST

TERMINAL

HUM -

HUMIDIFIER

(24-VAC 0.5

AMP MAX)

HUM

10

→

→

→