Adjustments – Great Plains YP925TD Operator Manual User Manual

Page 42

401-755M

02/23/2011

38

YP625TD and YP925TD

Great Plains Manufacturing, Inc.

Adjustments

To get full performance from your YP625TD and

YP925TD planter, you need an understanding of all

component operations, and many provide adjustments

for optimal field results. Some of these have been

covered earlier in this manual.

Even if your planting conditions rarely change, some of

these items need periodic adjustment due to normal

wear.

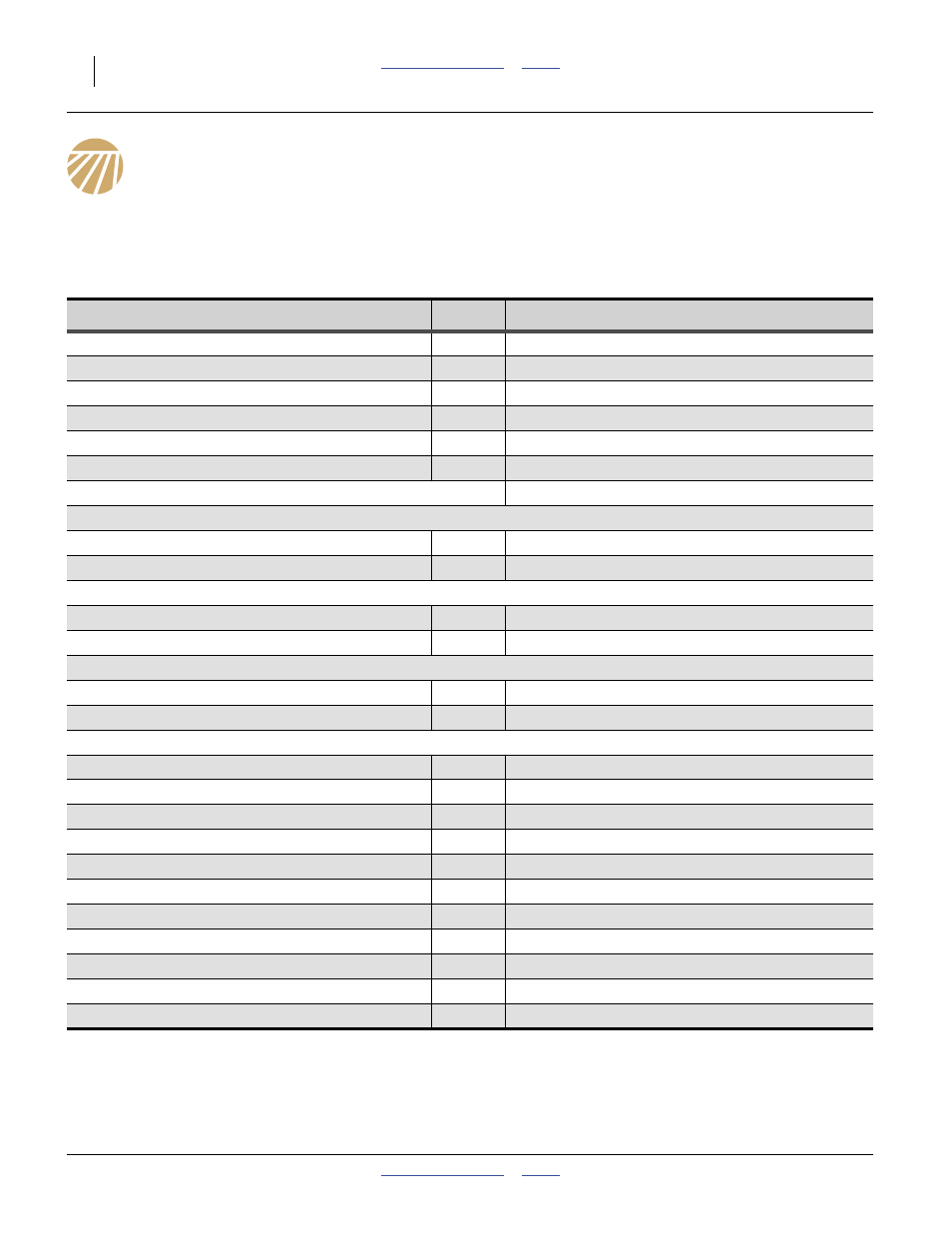

Adjustment

Page

The Adjustment Affects

Frame height

Planting depth consistency

Frame level

Planting consistency

Flat ground Planting

Planting when not on 18 cm beds

Air System

Fan Speed

Optimal seed distribution

Meter Pressurization (values from SRM

a

)

42

Consistent seed flow and disk singulation

Planting Rate

SRM

a

Refer to Seed and Fertilizer Rate manual

Marker Adjustments

Marker Extension

Intended swath spacing

Marker Speed Adjustment

Reliable marker operation

Dry Fertilizer Adjustments

Fertilizer Rate

SRM

a

Application rate

Dry Fertilizer Release

Fertilizer placement

Frame-Mounted Row Accessories (Options)

Terra-Tine Row Cleaners (Option)

Row preparation

Frame-Mounted Coulters (Option)

Row pre-furrow depth and trash cutting

25AP Row Unit Adjustments

Opener Depth

Planting depth

Row Unit Down Pressure

Planting depth uniformity

Row Unit Lock-Up

62

Single/twin-row operation

Rigid Row Cleaner Adjustments (Option)

Row preparation

Opener Disk Adjustments

Seed depth, seed-to-soil contact

Side Depth Wheels

Seed depth, prevents plugging

Adjusting Gauge Wheel Scrapers

Consistent seed furrow depth

Seed Meter Setup and Adjustment

Consistent seed population

Seed Firmer Adjustments (Option)

Seed-soil contact

Press Wheel Adjustment

Effective soil coverage

Monitor Adjustments

PM

b

Refer to Seed Monitor manual

a. SRM: Seed and Fertilizer Rate manual (401-754B)

b. PM: DICKEY-john

®

PM300-332-400 Planter Monitor Operator’s Manual (11001-1372)