Initial marker setup (option), Marker speed adjustment, Marker extension – Great Plains YP925TD Operator Manual User Manual

Page 124: Marker speed adjustment marker extension

120

YP625TD and YP925TD

Great Plains Manufacturing, Inc.

401-755M

02/23/2011

Initial Marker Setup (Option)

Marker Speed Adjustment

Overhead Sharp Object and Crushing Hazards:

Never allow anyone near the planter when folding or

unfolding the markers. You may be injured if hit by a folding or

unfolding marker. Markers may fall quickly and unexpectedly

if the hydraulics fail. Marker discs may be sharp.

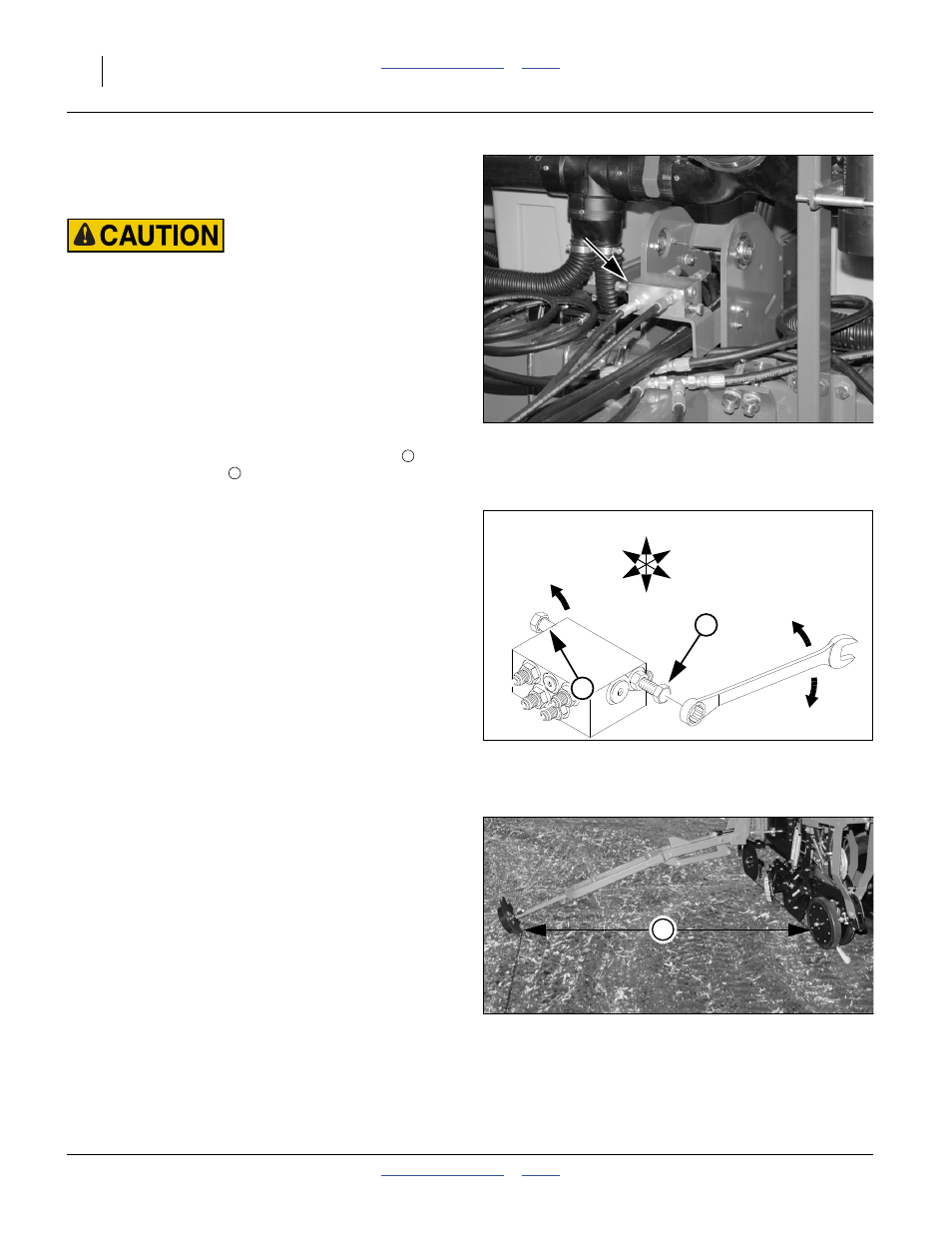

Refer to Figure 105 and Figure 106

Adjust folding speed for dual markers with hex

adjustment screws on the sequence valve body. The

valve sequence body is top center of main tool bar.

Loosen jam nuts before making adjustments.

There is one adjustment screw for raising speed

and

one for lowering speed

. You can identify adjustment

screws by markings stamped in valve body.

Turn adjustment screws clockwise (S: slower) to

decrease folding speed and counterclockwise (F: faster)

to increase folding speed.

With tractor idling at a normal operating speed, adjust

marker folding to a safe speed. Excessive folding speed

could damage markers and void the warranty.

After adjusting the folding speed, tighten jam nuts on hex

adjustment screws to hold settings.

Marker Extension

Marker extension needs to be adjusted once for the initial

YP625TD and YP925TD planter setup, and later only if

changing row spacing (including row shut-off for twin- or

single-row operation on a triple-row planter).

1.

Move the planter to a location where both markers

may be safely unfolded.

2.

Lower the planter. Pull forward and lower rows into

ground.

Note: Due to the relatively steep arm angles of short

markers, extension measurements are likely to be

incorrect if the main tool bar is not at normal

operating height (66 cm).

ll

Figure 105

Marker Sequence Valve Location

31007

1

2

Figure 106

Marker Speed Adjustment

14048

F

S

S

1

2

U

D

B

F

R

L

ll

Figure 107

Marker Extension

31039

E