Caution – Great Plains 4000TT Operator Manual User Manual

Page 71

Great Plains Mfg., Inc.

Section 5: Operating and Maintenance

12/15/2004

Series I 1000TT - 4000TT Turbo-Till 586-043M

69

11. Check for any bolts that may need tightened

or retightened. Grease all the hinge points.

The hubs come pre-greased and will not need

more grease at this time.

12. Put lift cylinder transport locks in place and

refold the machine slowly. Put wing stop pins

in place. Always use the transport locks and

pins when moving from field to field. You are

now ready to go to the field.

13. See Section 2: Hydraulics for setting hydraulic

down pressure control valves.

General Operating Instructions and In-Field Adjustments

1. Remove the transport locks and pins and

unfold the machine.

2. Set the hydraulic down pressure using the

instructions provided on pages 44 & 45

Caution: Never leave tractor valve

centered when unfolded with machine

in motion

. Machine damage may occur when

wings flex. The hydraulic down pressure

cylinders have no wing flex capability and oil

flow is required when the wings flex up or

down. You must have the tractor fold hydraulic

lever in continuous downward flow or “float”

position before the wings can flex over terrain

in the raised or lowered lift position.

3. If possible have someone observe the machine

during first time operation for levelness—front

to rear and wings to center frame. Adjust each

as needed. For front to rear, either extend or

shorten the length of the turnbuckle on the self-

leveling system. Never run the machine with

the back lower (deeper) than the front. To

adjust the machine from side to side, use the

lift turnbuckle on each wing

4. For best results, if at all possible, run the

machine at a slight angle to the rows. This will

improve trash flow and help spread the residue

more evenly throughout the field.

5. When you have the machine set to the desired

working depth, set the depth stop on the depth

control bar. This is located at the front of the

machine. This will maintain a constant depth

each time after raising and lowering the

machine. Slight tire to ground pressure

should be maintained to prevent cylinder

pin and clevis wear.

6. If after setting the depth stop, the detent on the

tractor kicks out before the stop contacts the

button on the depth stop, slow the hydraulic

flow speed down. If this problem still persists,

contact the factory service representative for

other possible adjustments.

7. Adjust the drag to leave the desired results

while maintaining the trash flow through the

drag.

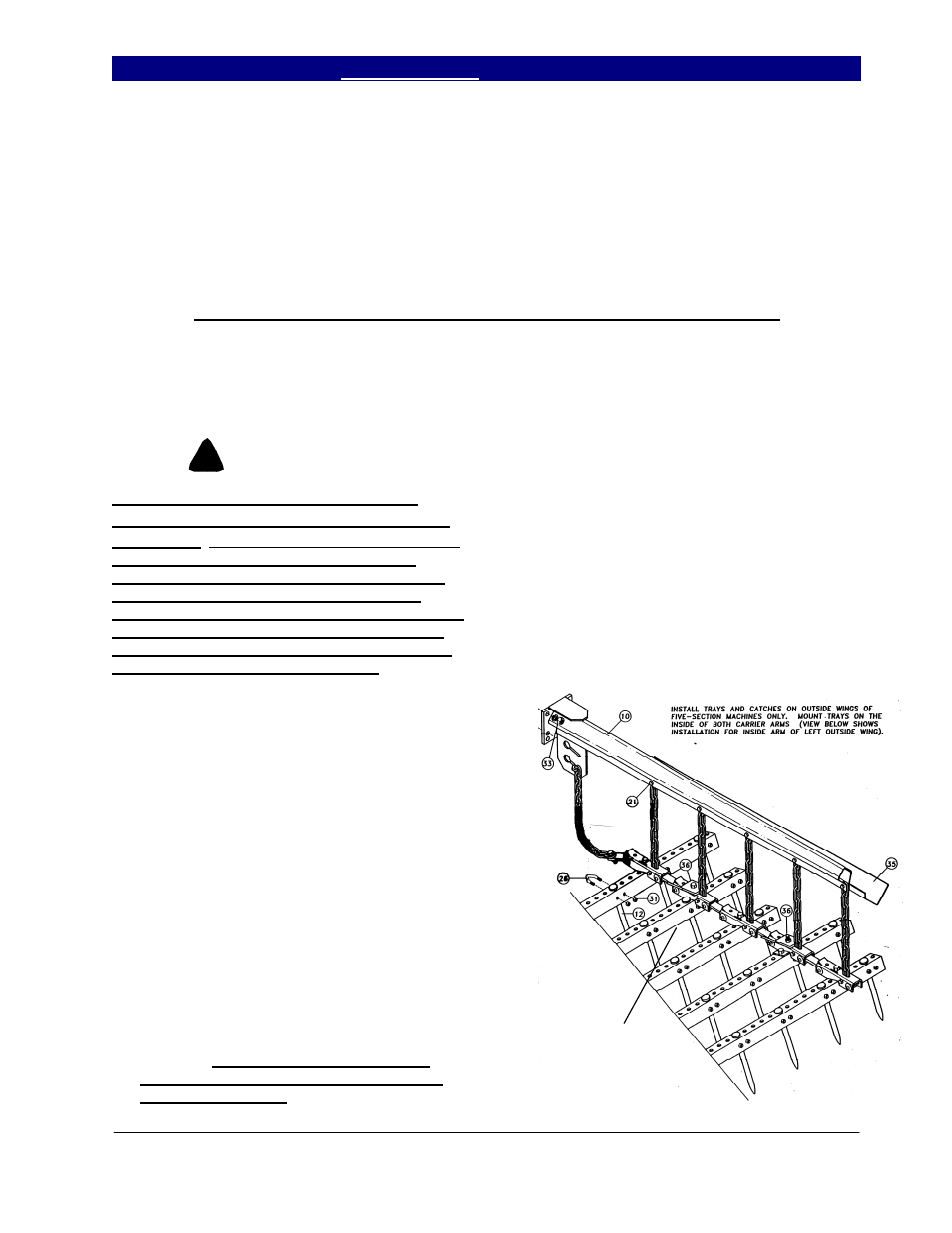

a.) On the spike drag, start with 5 links

hanging from the chain in drag arm bottom

slot. (This is the starting point for worst

conditions.) The cleaner the ground, the

shorter the pull chain may be pulled up.

On the spike drag, one of the links in the

first row of angles is turned over. This

ASSEMBLE WITH LINK UP AS

SHOWN. IN SOME

CONDITIONS THE FRONT

LINK MAY BE ASSEMBLED

DOWN TO HELP START

TRASH TO FLOW THROUGH

THE HARROW.

8/30/2005

!

CAUTION