Inside wing & lift assembly – Great Plains 4000TM Assembly Manual User Manual

Page 18

14

3500-4000TM

Great Plains Manufacturing, Inc.

586-537Q-ENG

12/03/2013

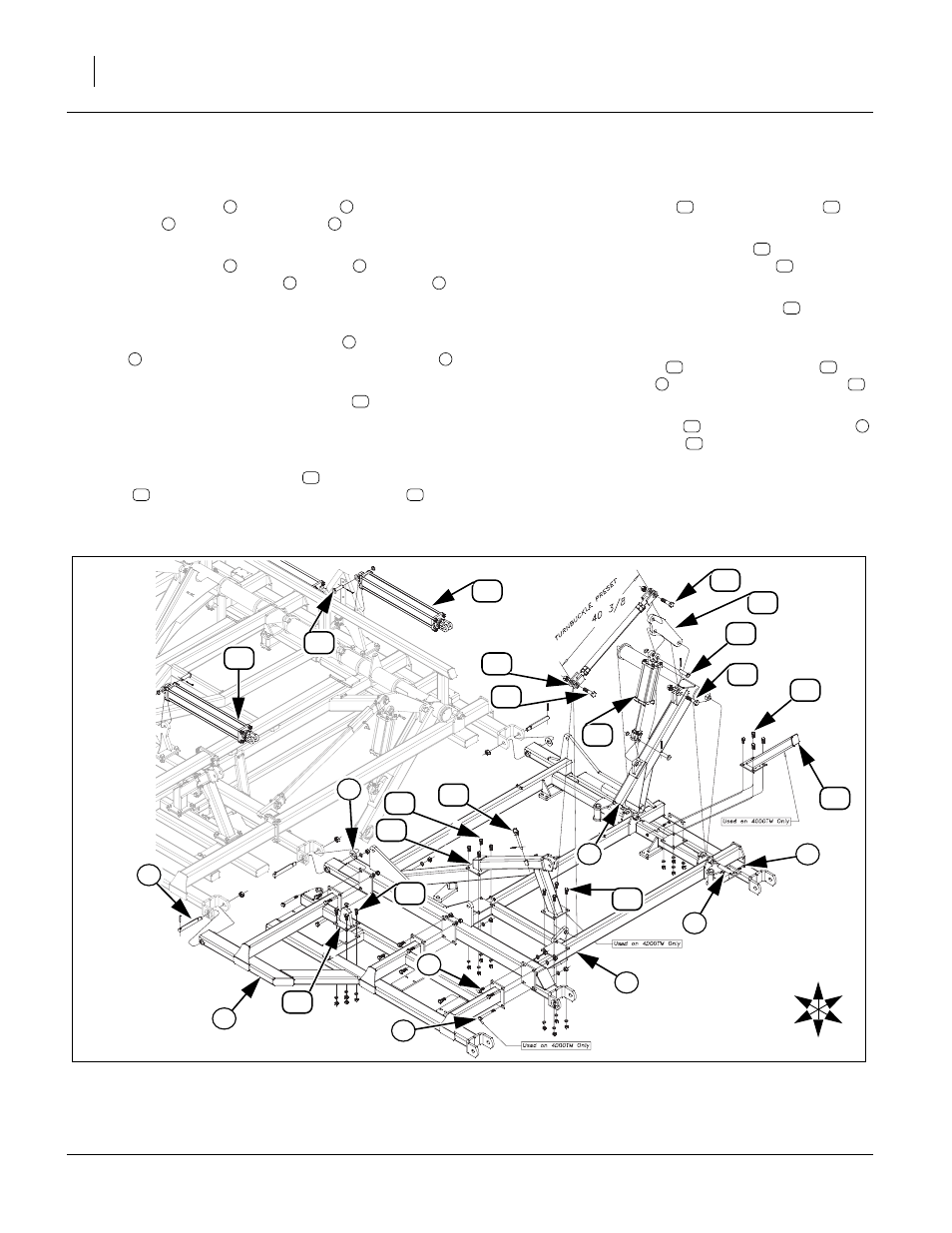

Inside Wing & Lift Assembly

Refer to Figure 12

43. Attach wing brace

to wing frame

with 3/4 x 2

hex bolts

and 3/4 x 7 hex bolts

(Model 4000

only), secure 3/4 lock washers and 3/4 nuts.

44. Attach wing brace

and wing frame

to center

frame with wing hinge pins

, 1 1/4 flat washers

(rear side of wing hinge tubes only, do not use

washer on wing brace bar) and 1 lock nuts.

45. Install LH and RH wing wheel arms

with 1 1/4 x 7

pins

, 3/8 x 2 1/4, Gr. 8, special thread hex bolts

and 3/8 top lock nut.

Note: Be sure wing turnbuckle assembly

is preset at

40 3/8” before installing as shown below. See

gang angle adjustment in “Operator Manual”

before going to field.

46. Install wing wheel turnbuckles

and cylinder mount

plate

in position shown with 1 x 4 hex bolts

and

1 lock nuts.

47. Install wing lift cylinders

with 1 x 3 1/8 pins

, 1.5

x 1.0 x.075 machine washers and 3/16 x 2 cotter pin.

48. Now the base end of fold cylinders

may be

hooked up with the 1 x 3 1/8 clevis pin

, 1.5 x 1.00

x 0.075 machine washer and 3/16 x 2 cotter pin.

49. Do not hook up rod end of fold cylinder

until sys-

tem is purged of air. See “Purging Hydraulic Sys-

tem” on page 28.

50. Attach front wing stop

and rear wing stop

to

plates of wing frame

with 5/8 x 1 1/2 hex bolts

,

5/8 lock washers and 5/8 nuts.

51. Attach wing stop bracket

to plate of wing frame

with 5/8 x 1 1/2 hex bolts

, 5/8 lock washers and 5/

8 nuts.

52. Tighten all bolts with lock nuts snug, but do not

torque. The rest of the bolts may be tightened to

specs, See “Torque Values Chart” on page 46.

1

2

3

4

1

2

5

6

7

8

9

10

10

11

12

13

14

15

14

15

16

17

2

18

20

2

18

U

D

F

B

L

R

6

4

Figure 12

Inside Wing & Lift Assembly

43141

3

1

5

8

12

2

7

11

10

12

13

19

16

15

15

14

18

9

18

17

12

14

18

18

20