Center transport – Great Plains 4000TM Assembly Manual User Manual

Page 13

Great Plains Manufacturing, Inc.

Assembly

9

12/03/2013

586-537Q-ENG

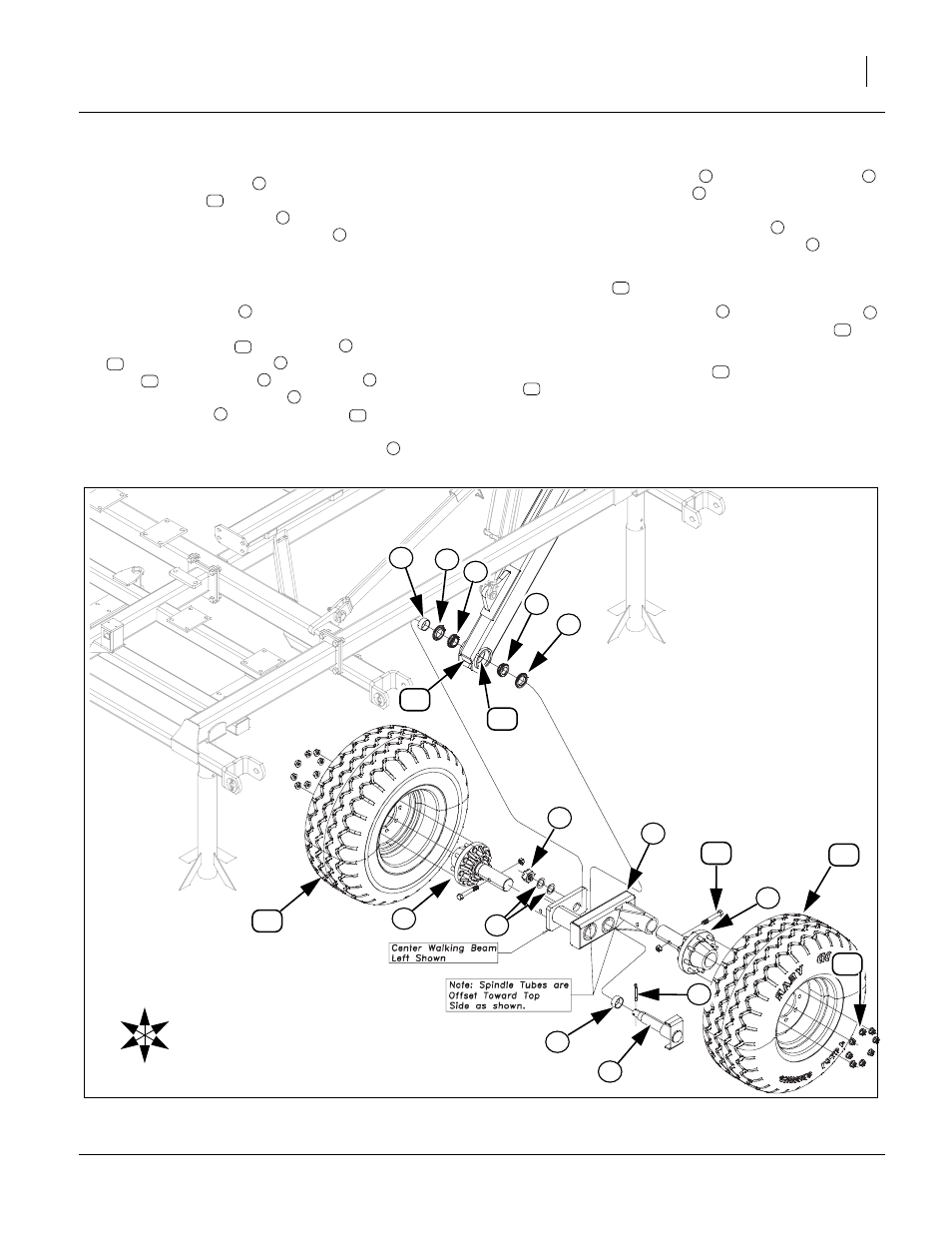

Center Transport

Note: The walking beam

may come pre-assembled to

torque tube

. If not pre-assembled start by

assuring the bearings

and inside of torque tube

is clean, packing the bearings

with grease and

following the steps closely to assure the correct

assembly of components.

Once the bearings

are packed with grease, slide

them (one on each side) into pre-installed bearing

cup of torque tube

. Slide seals

into torque tube

. Slide spindle sleeve

, one into inside of torque

tube

, through seal

and bearing

, the other

one over the pivot spindle

. Slide the LH and RH

walking beams

over torque tube

in orientation

shown with spindle tubes offset towards top. Be sure

holes are aligned and slide pivot spindle

through

from outside of machine. Secure with two 2.25 x 1.50

x 10ga machine washers

and 1 1/2 slotted nut

.

Tighten 1 1/2 slotted nut

down snug, then back off

1/8 to 1/4 turn, enough to align slot with hole in pivot

spindle and install 1/4 x 3 cotter pin

. Bend cotter

pin over to secure. Be sure walking beam

will pivot

freely but there should be no endplay.

10. Grease zerk

sparingly but do not over grease.

11. Slide hub/spindle assembly

into walking beam

and align holes. Secure with 3/4 x 5 hex bolts

and

3/4 top lock nut.

12. Attach tire/wheel assembly

with 3/4 flange nuts

.

13. Tighten all bolts with lock nuts snug, but do not

torque. The rest of the bolts may be tightened to

specs, See “Torque Values Chart” on page 46.

4

13

1

1

1

13

2

13

3

13

2

1

5

4

13

5

6

7

7

8

4

14

9

4

10

11

12

Figure 6

Center Transport

43137

12

2

U

D

F

B

L

R

5

1

6

10

3

3

2

1

4

7

8

9

11

11

9

13

14