Great Plains 3N-4020 Operator Manual User Manual

Page 95

Great Plains Manufacturing, Inc.

Troubleshooting

91

2013-10-29

196-359M

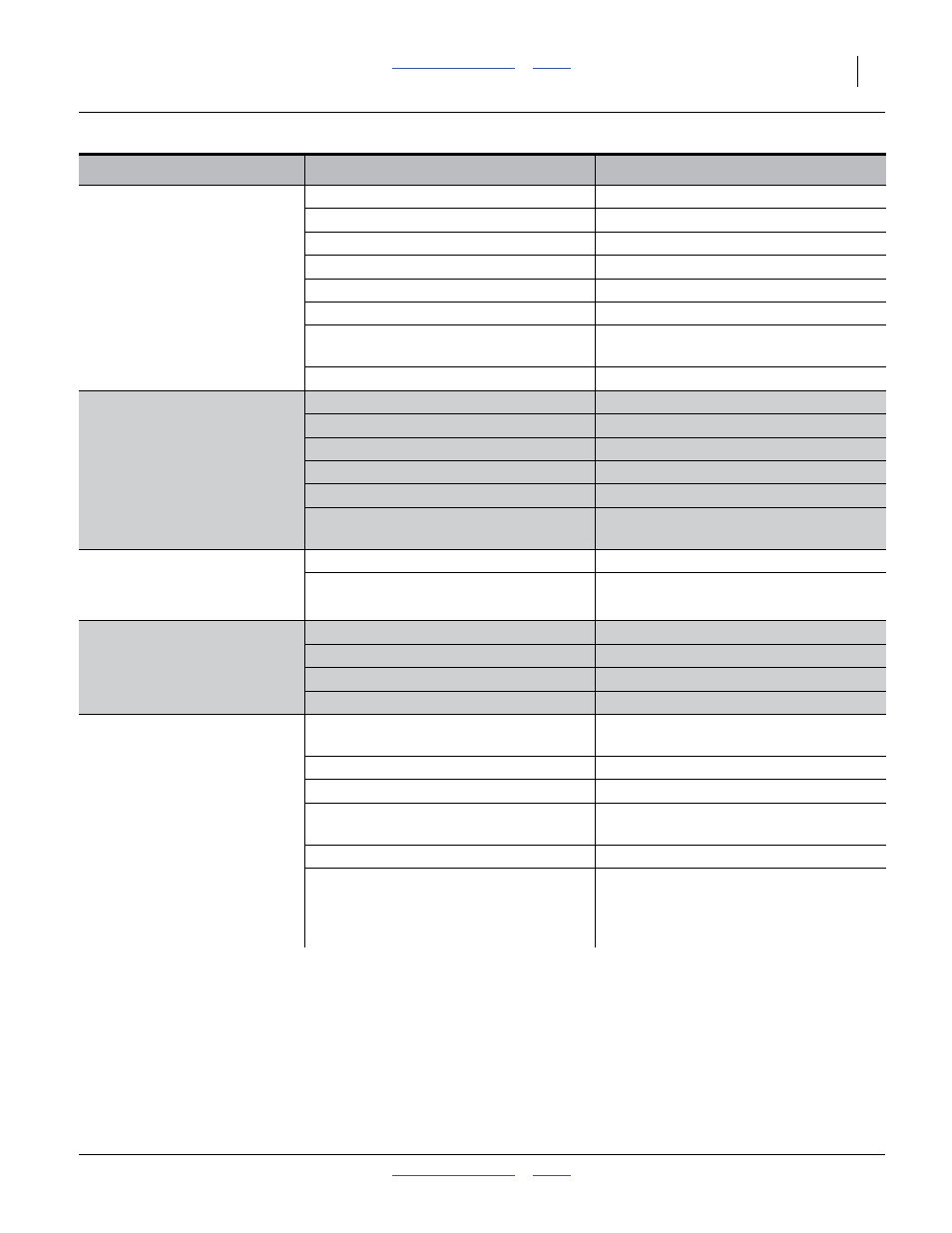

Uneven seed depth

Excessive field speed.

Reduce field speed.

Planting conditions too wet.

Wait until drier weather.

Seed-Lok building up with dirt.

Lock up Seed-Lok, pages 74, 82, 88.

Damaged or missing seed flaps.

Replace seed flaps.

Drill not level

Row down-force too light for conditions

Increase force, pages 71, 78, 85.

Partially plugged opener seed tube.

Lift up drill, expose bottom of seed tube

and clean out.

Low tire pressure

Check tires

Opener disks not turning

freely

Opener plugged with dirt.

Clean opener.

Planting conditions too wet.

Wait until drier weather.

Seed-Lok is plugging opener.

Lock up Seed-Lok, pages 74, 82, 88.

Failed disk bearings.

Replace disk bearings.

Bent or twisted opener frame.

Replace opener frame.

Partially plugged opener seed tube.

Lift up drill, expose bottom of seed tube

and clean out.

Press wheels not

compacting the soil as

desired

Too wet or cloddy.

Wait until drier weather or rework ground.

Incorrect press wheel depth.

Reset press wheel depth, pages 74, 82,

89.

Excessive seed cracking

Excessive field speed.

Reduce field speed.

Unclean seed.

Use clean seed.

Damaged, old or dry seed.

Use clean, new seed.

Seed cup door handle not open enough. See page 29.

Drill boxes do not empty

evenly

Opener seed tube plugged.

Lift up drill, expose bottom of seed tube

and clean out with wire.

Drive chains missing or damaged.

Replace drive chains.

Planting around fields vs. back-and-forth. Correct planting operation.

Rough field conditions may move seed in

the box.

Seed cup(s) are shut off.

Open seed cup(s).

Some models do not have the same

number of seed cups between each bulk-

head divider. The section with more seed

cups will empty sooner.

Verify number of seed cups in each box.

Problem

Cause

Solution