Unfolding the drill – Great Plains 3N-4020 Operator Manual User Manual

Page 28

24

3N-4010F/3N-4010HDF/3N-4020F

Great Plains Manufacturing, Inc.

196-359M

2013-10-29

Note: There are two key points to remember when oper-

ating the lock cylinders.

a. All seven lock cylinders are plumbed together,

and all move at the same time.

b. Operate the lock circuit lever (Retract/Neutral)

only once to fold. As the cylinders move, they

unlock 6 points then stop in a “ready to fold

position.” When the drill is folded, the 7th lock,

spring loaded, snaps shut, locking the drill.

5.

Extend the Fold cylinder circuit lever to slowly fold

wings forward. The transport lock automatically cap-

tures the right wing tool bar for transport.

Note: It may be necessary to ease forward slightly with

the tractor to assist wings in folding completely.

Unfolding the Drill

Machine Damage Risk:

Unfold only when the drill is raised and locked up.

Unfold the drill on level ground with the tractor transmis-

sion in neutral.

Crushing, Pinch-Point and Overhead Hazards:

To prevent serious injury or death:

▲ Always use transport locks when drill is folded.

▲ Fold only if hydraulics are bled free of air and fully charged

with hydraulic oil.

▲ Stay away from frame sections when they are being raised

or lowered.

▲ Keep away and keep others away when unfolding drill.

Note: When unfolding, operate the lock circuit exactly in

reverse of folding. Operate the circuit once (Ex-

tend/Neutral). Remember that when the cylinders

move, they release one lock, and enable six others,

stopping in a “ready to unfold” position. As the drill

is unfolded, the six spring loaded locks snap shut,

locking the drill.

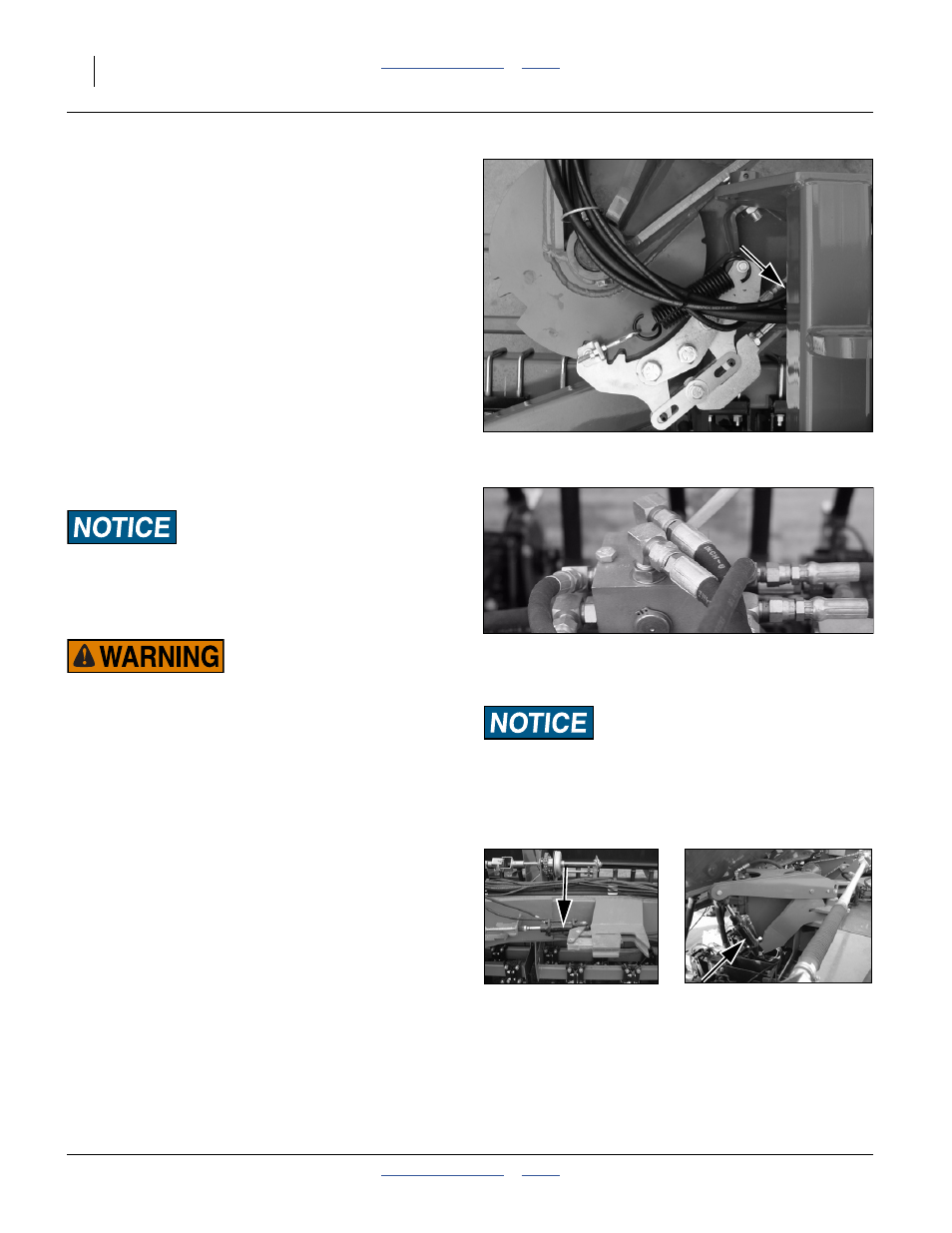

Refer to Figure 23

1.

Check selector valve set to Locks.

Figure 22

Swivel Lock Cylinder

27183

Pinch/Crush Risk:

Center section of drill moves forward while unfolding.

Tractor may move backward. Keep all personnel clear of drill

and tractor wheels.

Figure 23

Unfold: Drive/Lock Selector Valve

21844

Figure 24

Transport/Tool Bar Lock Cylinders

21841

21845