Maintenance and lubrication, Maintenance – Great Plains 1007NT Operator Manual User Manual

Page 45

10/06/2010

150-290M

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

41

Maintenance and Lubrication

Maintenance

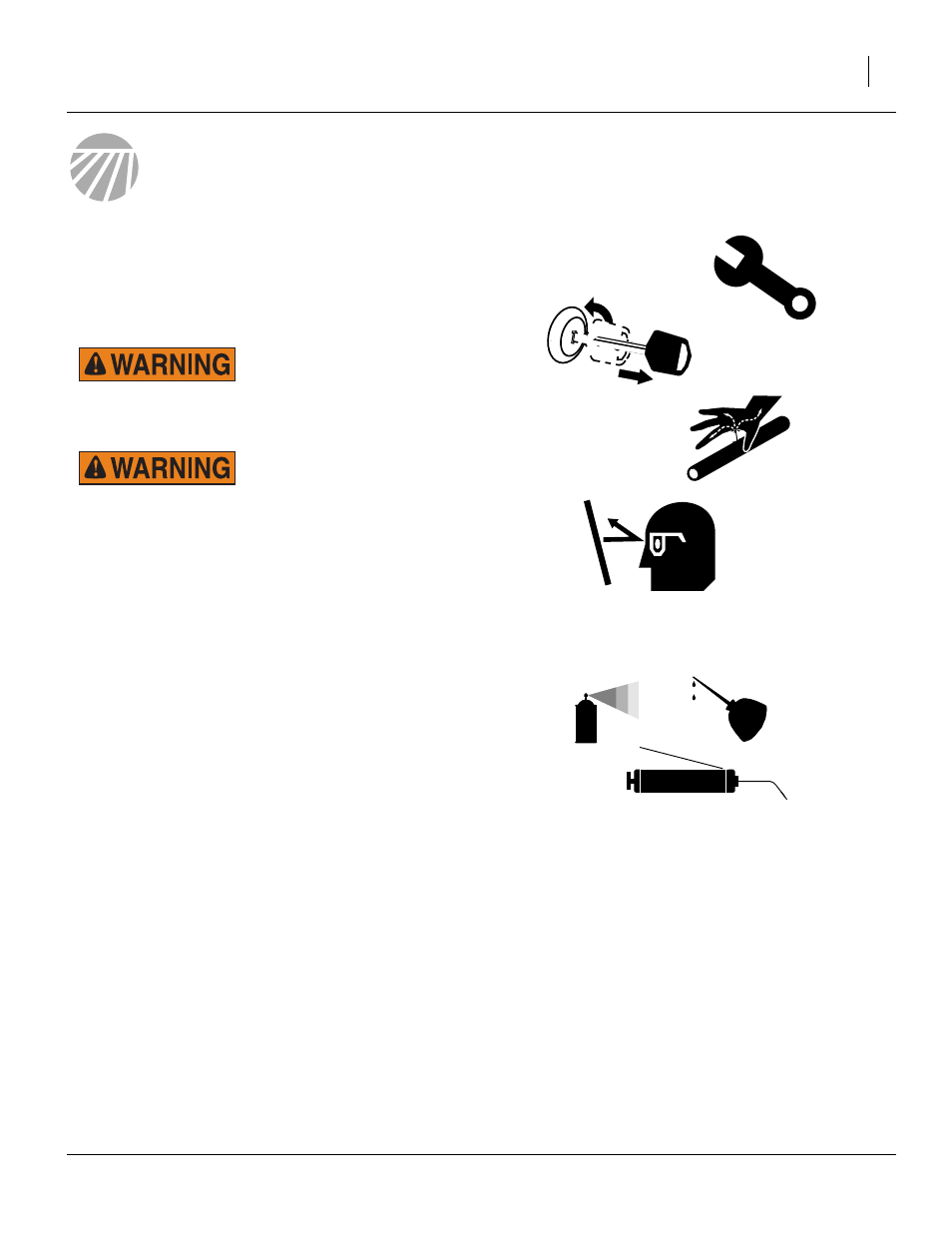

Proper servicing and maintenance is the key to long

implement life. With careful and systematic inspection,

you can avoid costly maintenance, downtime and repair.

Always turn off and remove the tractor key before making

any adjustments or performing any maintenance.

You may be severely injured or killed by being crushed under

the falling implement. Always have transport locks in place

and frame sufficiently blocked up when working on implement.

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin. Check all hydraulic lines and fittings before

applying pressure. Fluid escaping from a very small hole can

be almost invisible. Use paper or cardboard, not body parts,

and wear heavy gloves to check for suspected leaks. If injured,

seek immediate medical attention from a physician familiar

with this type of injury.

1.

After using the drill for several hours, check all bolts

to be sure they are tight.

2.

Lubricate areas listed under “Lubrication” on page

47.

3.

Adjust idlers to remove excess slack from chains.

Clean and use chain lube on all roller chains as

needed.

4.

Inflate tires as specified in

5.

Clean out build up of seed treatment in feed cups.

6.

Replace any worn, damaged or illegible safety

decals. Order new decals from your Great Plains

dealer. See “Safety Decals” on page 5.

OFF