Hydraulic hose hookup, Re-phasing cylinders, Hydraulic hose hookup re-phasing cylinders – Great Plains 1007NT Operator Manual User Manual

Page 19

Great Plains Manufacturing, Inc.

Preparation and Setup

15

10/06/2010

150-290M

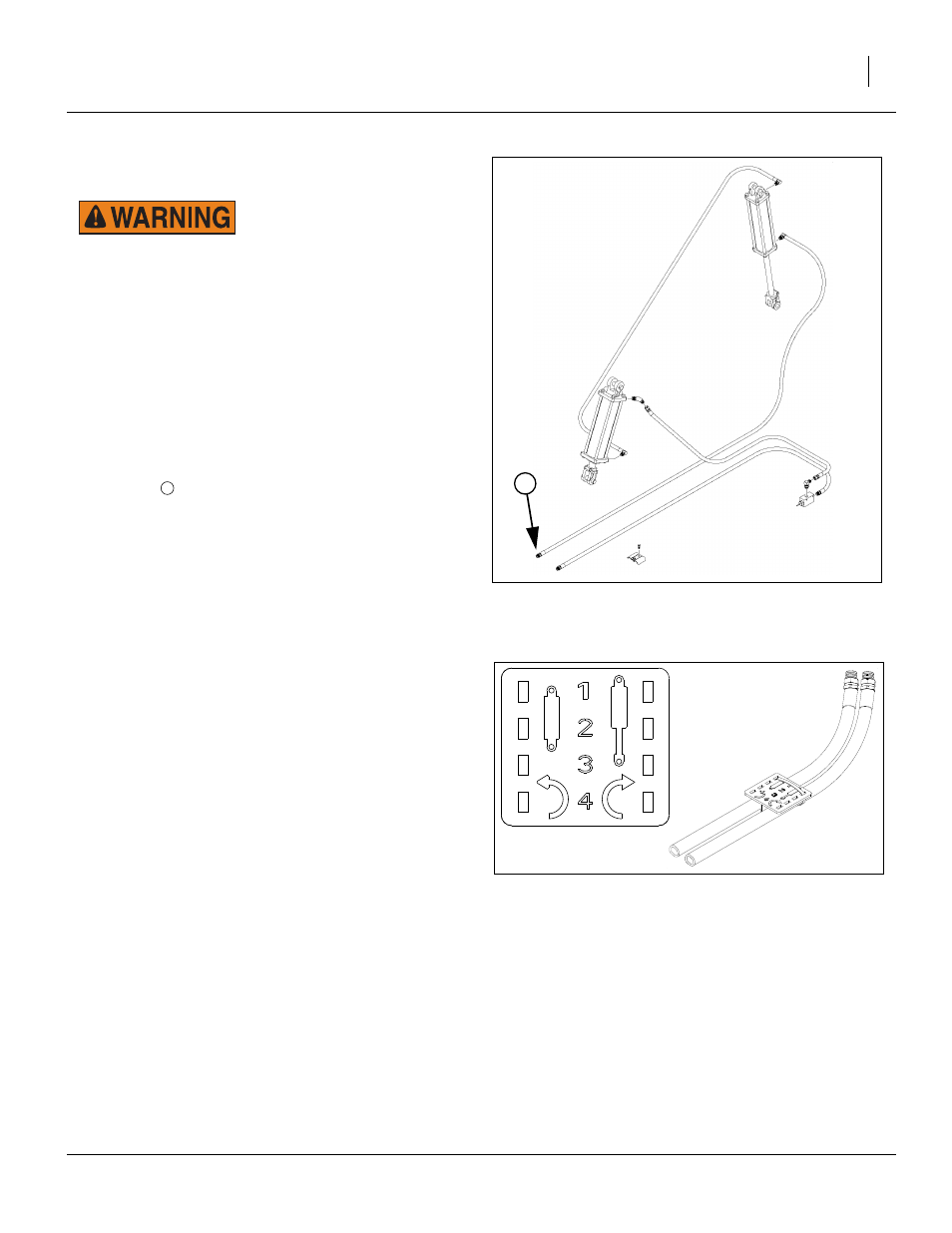

Hydraulic Hose Hookup

Connect hydraulic system to tractor before lifting the drill.

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin. Check all hydraulic lines and fittings before

applying pressure. Fluid escaping from a very small hole can

be almost invisible. Use paper or cardboard, not body parts,

and wear heavy gloves to check for suspected leaks. If injured,

seek immediate medical attention from a physician familiar

with this type of injury.

The hydraulic system of the 1007NT drill has one circuit,

which controls two functions:

• Forward lift with depth-control stop valve.

• Rear lift-assist, which is fully retracted in the field.

Note: Prior to first use, adapt the

1

⁄

2

in male NPT hose fit-

tings

to connectors compatible with the tractor.

Use liquid pipe thread sealant (not tape) on NPT.

A poppet style QD (Quick Disconnect) to

1

⁄

2

in FNPT

coupler is available as Great Plains part 811-856C.

Refer to Figure 4

To distinguish hoses on the same hydraulic circuit, refer

to plastic hose label. The hose under an extended-cylin-

der symbol feeds a cylinder base end. The hose under a

retracted-cylinder symbol feeds a cylinder rod end.

12. Connect the hydraulic hoses to the tractor remotes.

Re-phasing Cylinders

The lift cylinders may, after a period of time, get out of

time or phase. The effects of this can be seen when not

all cylinders are fully extended at full lift.

To re-phase the cylinders, raise drill completely and hold

tractor hydraulic lever on for a few seconds to give cylin-

ders time to re-phase.

Each time drill is raised out of ground momentarily

reverse hydraulic lever immediately after re-phasing to

allow cylinders to retract about

1

⁄

2

in (13mm). This helps

in maintaining a level drill.

Note: Having cylinders become gradually out of time is

different than air trapped in the system. Each con-

dition is corrected differently. Perform “Hydraulic

Setup” on page 73 to purge air from the system.

Figure 4

Drill Hydraulic System

31608

1

Figure 5

Plastic Hose Label

817-348c

17641