Coulter depth (individual rows), Drill weight adjustment – Great Plains 1007NT Operator Manual User Manual

Page 36

32

1007NT

Great Plains Manufacturing, Inc.

150-290M

10/06/2010

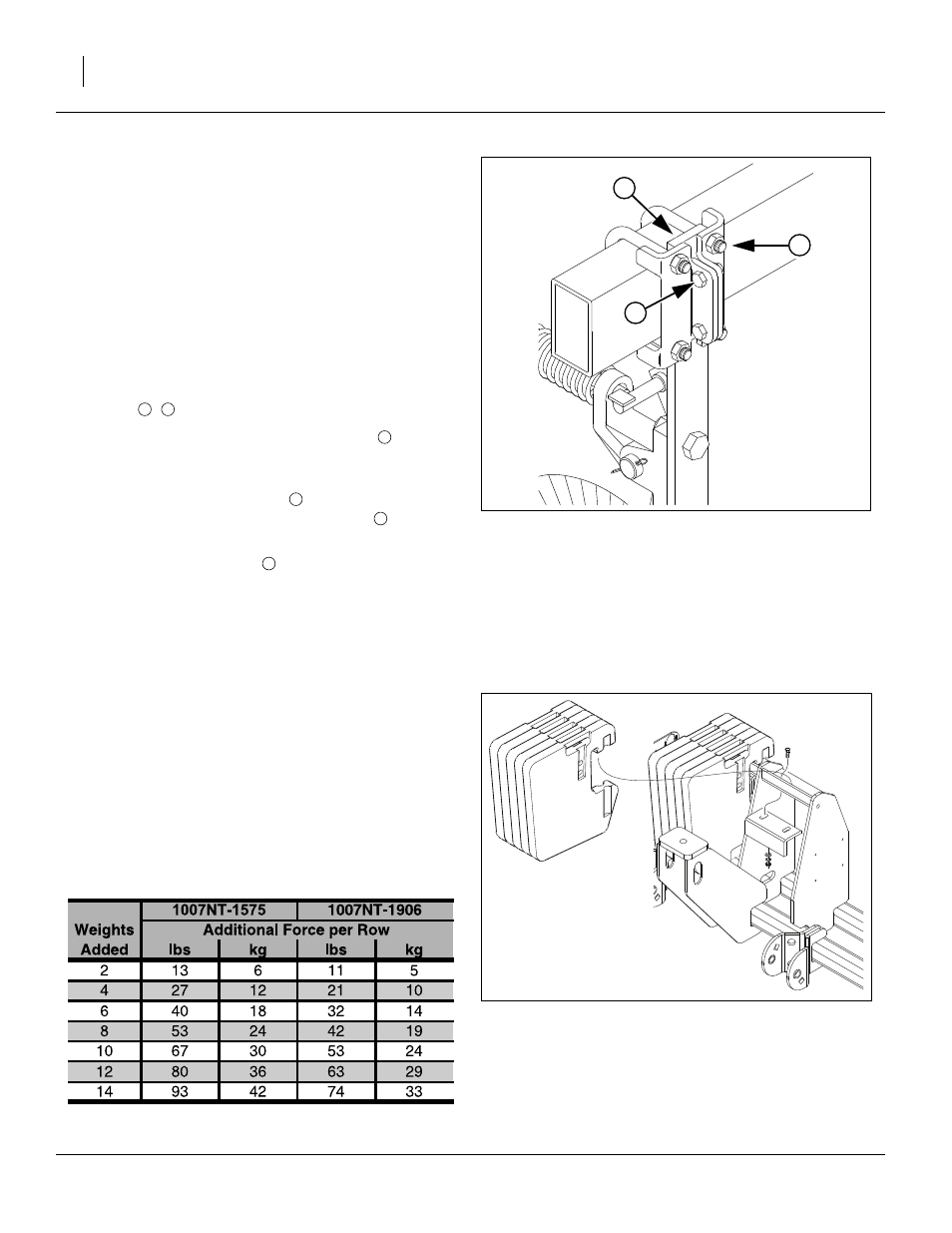

Coulter Depth (Individual Rows)

The running depth of all coulters is adjusted simulta-

neously by changing the tool bar height. Adjusting the

height of a small number of coulters may be useful for

rows in tire tracks.

Adjust individual coulters as follows.

1.

On level ground, lower the drill until coulters just

touch the ground.

2.

Raise the drill by the extra amount you need to lower

the rows in tracks.

At each coulter to be adjusted, slightly loosen all six

bolts (

,

) at the mount.

4.

Using a rubber mallet, tap the spring bar

down until the bottom edge of the coulter disc is at

ground level.

5.

Tighten the two clamp bolts

until both U-bolts are

firmly against the edge of the spring bar

mal for there to be a small gap between the clamps.

6.

Tighten the four U-bolts

7.

Lower the drill and pull forward 30 feet (10m).

8.

Check coulter blade to opener blade (furrow center-

line) alignment.

Drill Weight Adjustment

In heavy no-till conditions, or if it is otherwise necessary

to increase coulter spring force, extra frame weight is

probably required (or the higher forces will just lift the drill

off the ground, resulting in uneven planting depth and

unreliable ground drive operation).

Adding weight requires pairs of user-provisioned stan-

dard “suitcase” tractor weights.

The standard includes two brackets. Each bracket

accepts up to seven 100 pound (45 kg) weights. The fol-

lowing table shows the additional force per row that the

kit can provide.

Note: Do not adjust the bar height of all coulters. Use

the depth control valve to set group coulter height

(page 29).

Figure 20

Frame-Mounted Coulter Height

10300

1

2

3

3

2

Note: Maximum added weight is 1500 pounds (680kg).

Distribute the weight equally on both brackets.

Figure 21

Adding Weights

28469