Great Plains 1007NT Operator Manual User Manual

Page 43

Great Plains Manufacturing, Inc.

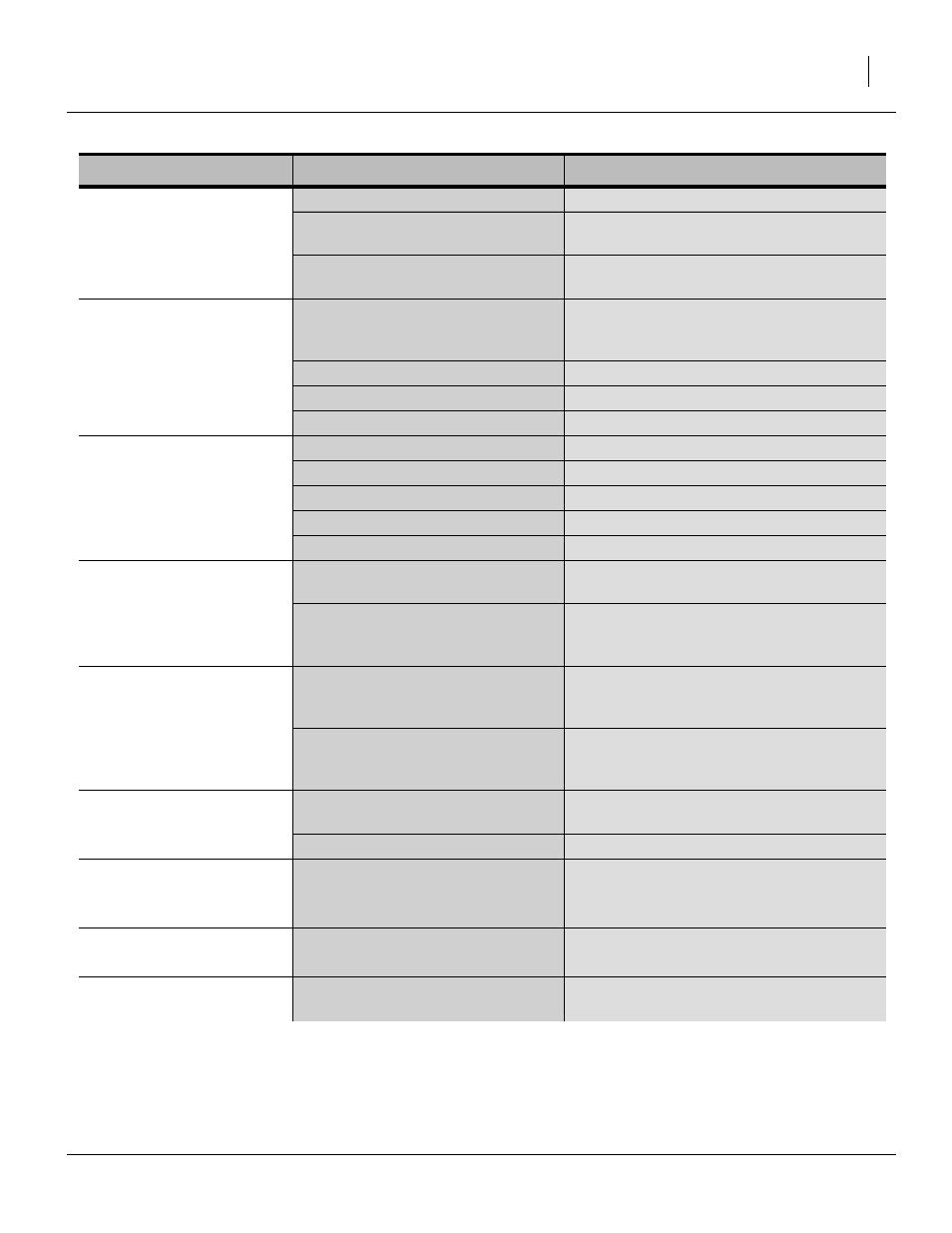

Troubleshooting

39

10/06/2010

150-290M

Press wheels not

compacting soil as desired

Too wet or cloddy.

Wait until drier weather or rework ground.

Press wheel depth does not match

coulter depth.

Readjust press wheel depth, page 37.

Not enough down pressure on disc

openers.

Increase down pressure on openers, page

36.

Boxes not emptying evenly Some boxes do not have same num-

ber of feed cups between each divider

of bulkhead.

Load more material than required. Re-distrib-

ute when re-loading.

Main box seed cup door setting

Set all doors the same, per seed size.

Seed plug(s) installed

Remove seed plug(s).

Meter or tube blocked.

Clear blockage.

Press wheel or openers

plugging

Planting conditions too wet.

Wait until drier weather.

Too much down pressure on openers. Reduce down pressure on openers, page 36.

Backed up with drill in the ground.

Clean out and check for damage.

Failed disc bearings.

Replace disc bearings.

Scraper worn or damaged.

Replace scraper.

Feed cup sprockets locked

up or twisted feed cup

drive shaft

Foreign matter lodged in one or more

feed cup sprockets.

Clean out feed cup sprockets. Use clean

seed.

Dried liquid insecticide inside feed

cups.

Remove build up by disassembling each feed

cup and scraping foreign substance from turn

surfaces.

Coulters not going deep

enough

Not enough down pressure.

Adjust coulters when a few rows are involved

(page 32). Add weight when all rows are

affected (page 32).

Row down pressure set too high

(reducing weight available to coulters)

Reduce row down pressure to standard

(page 36). Set coulters to prepare furrow

more aggressively (page 28).

Coulters and drill going too

deep

Coulters set too deep or spring force

too high

See page 28 for correct adjustment.

Incorrect press wheel adjustment.

Set press wheels to a shallower depth.

Coulters and openers

plugging in no-till

conditions

drill at a slight angle to rows.

Small seeds box not

emptying evenly

Adjustable divider not set evenly.

Move adjustable divider to create more vol-

ume in areas that run out first.

Chain

Debris, retainer clip

Be sure retainer clip is facing opposite way of

chain travel. See page 46.

Problem

Cause

Solution