Final adjustment and regulating procedures – SARGENT 281 Series Cast Iron Closer User Manual

Page 3

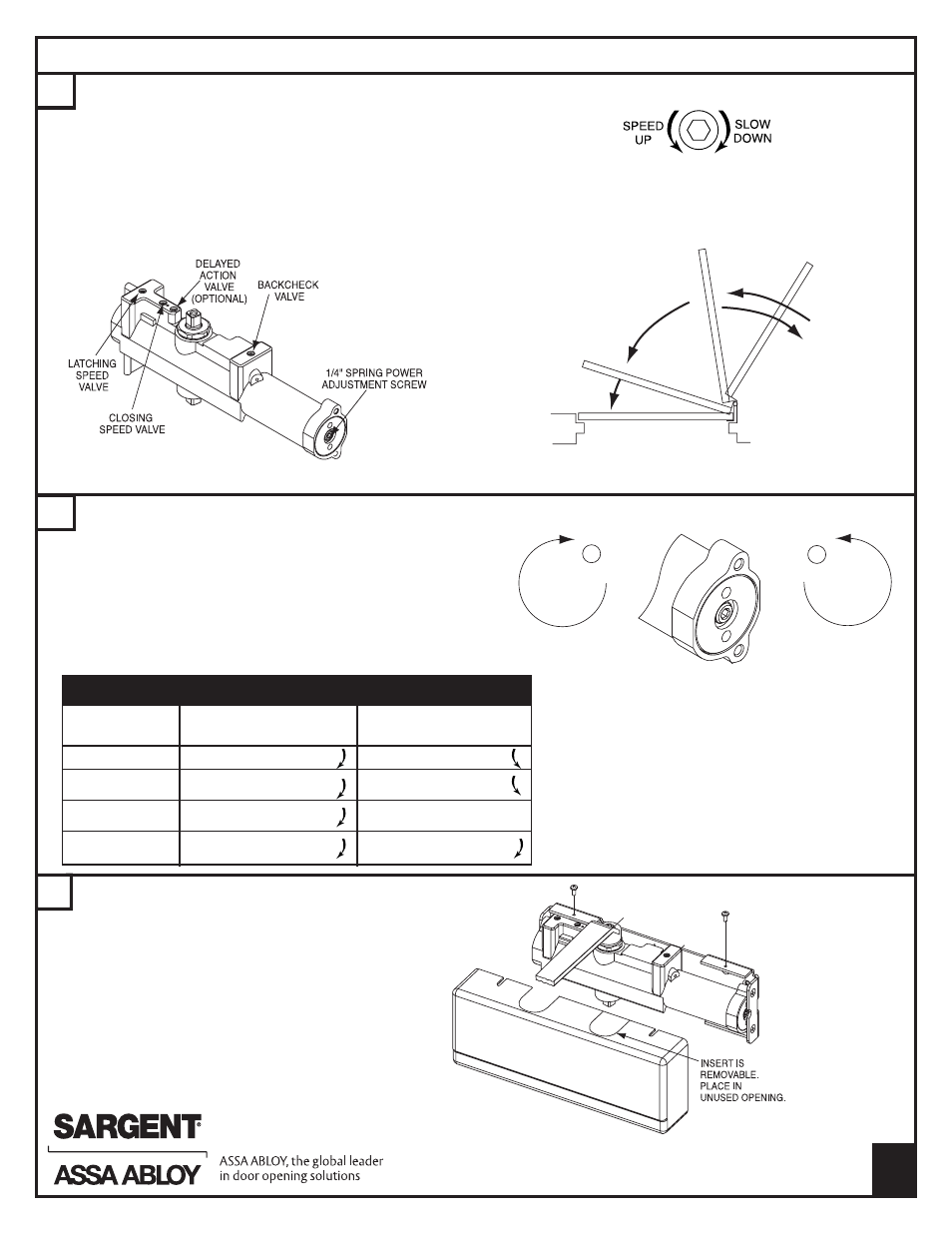

FINAL ADJUSTMENT AND REGULATING PROCEDURES

F

3

H

INSTALL COVER WITH TWO SCREWS AS SHOWN.

SSP INCLUDES HANDED METAL COVER

(NOT SHOWN) AND 6 LOBE SECURITY SCREWS.

G

Adjust Closing power to the minimum required to reliably

close and latch door

· If door is hard to open, decrease power slightly

· If door does not latch, increase power as required

· Use the chart below as a starting point

Doors adjusted with high closing power to overcome strong

draft conditions may exceed ADA standards

+

-

DOOR WIDTH

EXTERIOR DOORS

*INTERIOR DOORS

(INCHES)

24-30

Turn screw 2-7

Turn screw 1-5

30-36

Turn screw 7-11

Turn screw 3-6

36-42

Turn screw 11-15

FACTORY SET

42-48

Turn screw 15-17

Turn screw 8 & up

SPRING POWER ADJUSTMENT GUIDELINES

INCREASE

POWER

DECREASE

POWER

ADJUST CLOSING

POWER WITH A 1/4"

HEX WRENCH

· Adjust Door speed, and Latching speed valves to

achieve the desired closing time. Recommend 6

seconds minimum from 90° to the closed position.

· If Backcheck is required, adjust valve to achieve a

slight cushioning effect. Auxiliary stop required

· If closer is equipped with Delayed Action, regulate

valve to achieve the desired delay.

USE 1/8" HEX WRENCH

TO ADJUST VALVES

B

ACKCHECK

RANGE

D

ELAYED ACTION

RANGE

C

LOSING SPEED

RANGE

L

ATCHING SPEED

RANGE

Copyright © 2012, 2014, Sargent Manufacturing Company, an ASSA ABLOY

Group company. All rights reserved. Reproduction in whole or in part without the

express written permission of Sargent Manufacturing Company is prohibited.

A7921C