Winchester Repeating Arms 101 User Manual

Page 24

22

23

c

hoke

t

ube

i

nStallation

1. Place the “safety”/selector in the on safe position.

Always make sure the shotgun is completely unloaded.

Always keep the muzzles pointed in a safe direction.

2. Before installing a tube, check the internal choke tube

threads in the muzzle, as well as the threads on the

choke tube to be sure they are clean. Lightly oil the

threads with a high-quality, lightweight gun oil.

NOTICE! Failure to clean and oil the threads on

the choKe tube could result in the choKe tube

seiZing in the barrel.

3. Using your fingers, screw the appropriate tube into the

muzzle of the barrel, tapered end first, notched end

outward. When it becomes finger-tight, use the choke

tube wrench to firmly seat the tube.

NOTICE! the choKe tubes should be Periodically

checKed to assure they are tight and FirMly

seated. beFore checKing, Follow all choKe tube

reMoval and installation “saFety”/selector

guidelines Previously outlined.

c

hanging

l

ength

of

p

ull

(S

pecial

m

oDelS

)

beFore changing triggers or PerForMing

adjustMent Procedures, Place the “saFety” in

the on saFe Position. oPen the action and MaKe

All Model 101 shotgun barrels are threaded to accept

the Invector-Plus

™

choke system. Standard Invector,

WinChoke and Invector-Plus tubes are not

interchangeable. Confirm the choke system of your

shotgun by looking on the right side of the barrel where

the specifications are inscribed, where the choke markings

are normally located.

The constriction of each choke tube is indicated twice on

the choke tube: on the side of the tube, and indicated

with a “notch” code on the top rim of the tube. The

included universal choke tube wrench is used to remove

and install choke tubes.

Some target shotguns include premium extended choke

tubes. The constriction of premium choke tubes is

indicated twice on the choke tube: on the side of the

tube, and indicated with an abbreviation in the colored

band. The constriction of flush fit choke tubes is

indicated twice on the choke tube: on the side of the

tube, and indicated with a “notch” code on the top rim

of the tube. The included choke tube T-Wrench is used

to remove and install extended choke tubes.

Choke tubes are compatible with factory ammunition

that has been loaded in compliance with SAAMI

specifications, including magnum lead and steel shot

loads, sabots and shotgun slug loads.

Replacement and additional tubes and wrenches are

available from your Winchester Repeating Arms dealer, or

by contacting the Winchester Repeating Arms Customer

Service Department. See page 32 for contact information.

c

hoke

t

ube

S

election

To help you choose the correct choke tube for each

hunting and shooting situation, all Invector-Plus choke

tubes are inscribed on the side with the patterns

they produce with both lead and steel shot. Each

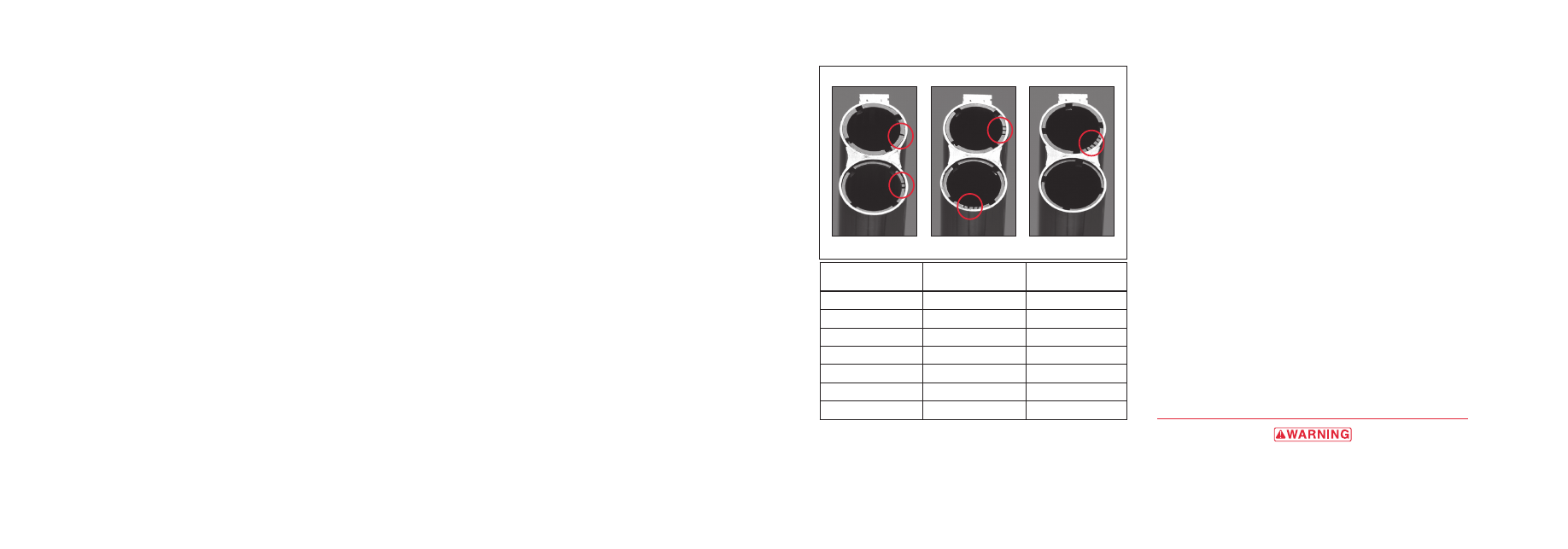

Invector-Plus tube also has notches in the top rim of the

tube (Figure 20, page 23). These notches are a code to

allow you to determine the choke designation while the

tube is installed. Rim notches refer specifically to lead

shot. Use the charts on this page to cross-reference from

lead to steel, and determine the appropriate tubes for your

ammunition and hunting/shooting situation.

Several choke tubes are supplied with your shotgun.

The choke tubes listed are also available as accessories.

Remember, WinChoke, Standard Invector and Invector-

Plus tubes are not interchangeable. Before removing or

installing tubes, or reading the rim notch code, make sure

your shotgun is completely unloaded and the “safety” is in

the on safe position.

c

hoke

t

ube

r

emoval

1. Place the “safety”/selector in the on safe position.

Always make sure the shotgun is completely unloaded.

Always keep the muzzles pointed in a safe direction.

2. Use the choke tube wrench to loosen the tube,

turning it counterclockwise. Finger-twist the tube the

rest of the way out of the barrel.

R i m

N ot c h e s

Pat t e R N w i t h

L e a d s h ot

Pat t e R N w i t h

s t e e L s h ot

e x t e N d e d * *

x - F u L L t u R k e y

* *

i

F u L L

*

i i

i m P. m o d i F i e d

F u L L

1

i i i

m o d i F i e d

F u L L

1

i i i i

i m P. c y L i N d e R

m o d i F i e d

i i i i i

s k e e t

i m P. c y L i N d e R

N o N ot c h e s

c y L i N d e R

c y L i N d e R

*

Not for use with steel shot. Using an over-tight choke constriction with

steel shot will result in an ineffective “blown” pattern.

**

Extra Full Turkey, extended with ports. Do not use with steel shot.

1

When more than one choke tube is listed for a given steel shot pattern, use

the more open choke listed for high velocity, larger shot size steel loads.

FIGURE 20

N o N ot c h e s

F i v e N ot c h e s

F o u R N ot c h e s

t h R e e N ot c h e s

t w o N ot c h e s

o N e N ot c h