Quick robotic torch – Tweco Quick Robotic Torch User Manual

Page 13

3-9

Quick Robotic toRch

SM-QRTORCH

INSTALLATION AND DISASSEMBLY

(h) Remove the steel hose clamps from the various hose

assemblies. Using pliers, position the tabs on the steel

clamps to allow the clamp to be held. Twist the tab

clockwise until the clamp breaks apart.

CAUTION

Do not bend the nipple(s) while twisting the tab(s)

to break the clamp apart.

(i) Remove the cable hose connector away from the

existing cartridge kit.

(j) Follow the above steps in reverse order to re-assemble

the new cartridge kit.

CAUTION

When connecting the cablehoz connector, be

sure to apply a high strength thread locking

adhesive compound to the threads of the brass

block assembly before threading the cablehoz

connector onto the block. This connection must

be tightened to a torque of 120 inch/pounds.

Failure to tighten this connection properly could

cause the power cable to overheat.

(k) Use the clamps, supplied with the cartridge kit, to

hold the inch switch cable in place. Refer to Figure

3-11.

CLAMP

Art # JB-00023

Figure 3-11: Location of Clamps

2. Follow the steps below to replace the cartridge kit on a

QRW and QRW-S torch and cable assemblies:

(a) Follow Steps (a) through (g) for removing the cartridge

kit on QRA, QRAS, QRWA, and QRWAS series torch

and cable assemblies.

(b) When replacing or re-installing the cartridge kit having

the nozzle sensing feature, the wire lead for the nozzle

sensing must be disconnected or connected inside

the molded housing.

(c) Using needle-nose pliers, pull the existing wire

lead away from the cartridge kit to the connector

assembly.

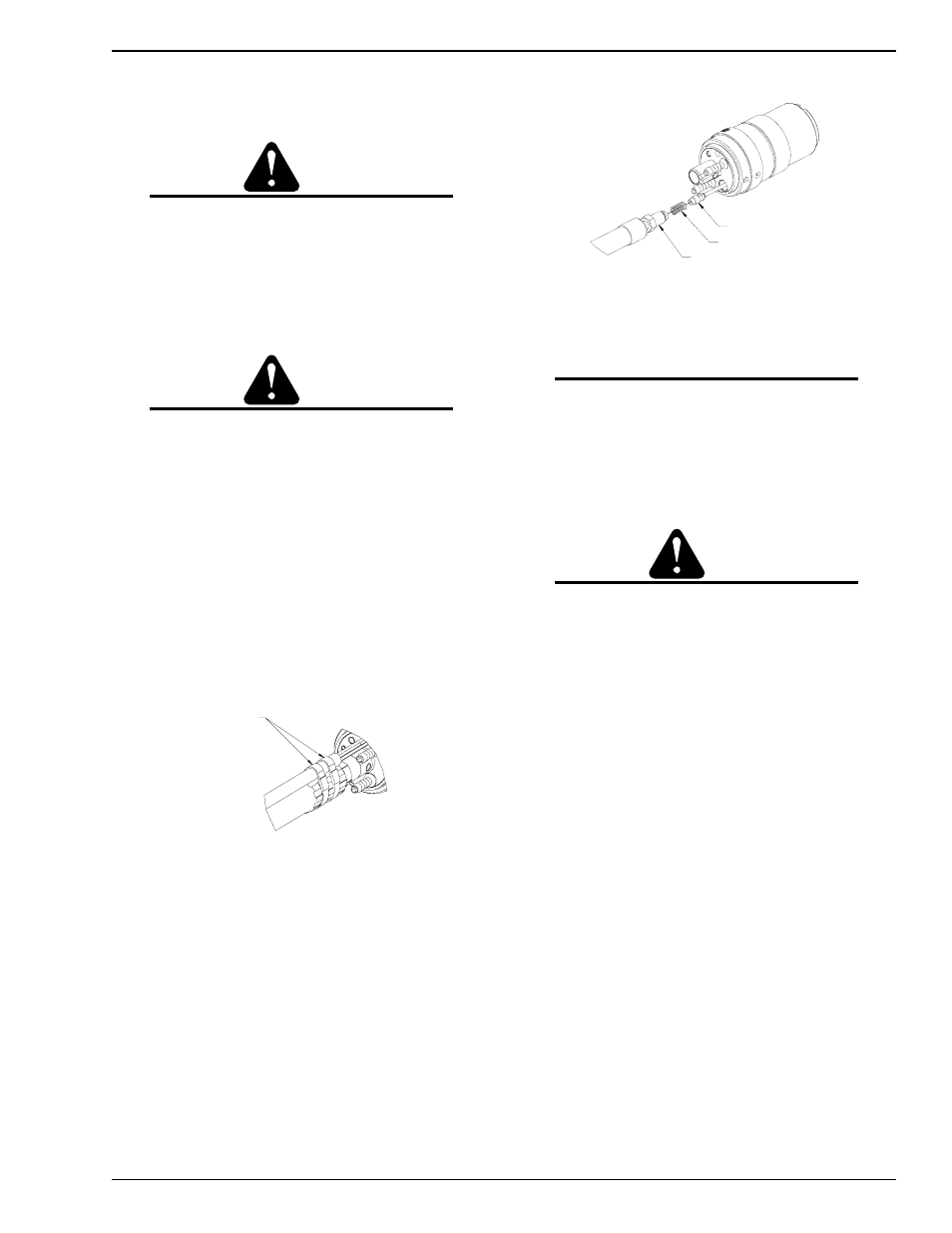

(d) Remove the threaded power cable connection from

the block assembly. Refer to Figure 3-12.

VALVE

SPRING

POWER CABLE

Art # JB-00024

Figure 3-12: QRW Series Check Valve

(e) Re-insert the lead wire coming from replacement

cartridge kit into the connector assembly.

NOTE

Make sure the components making up the check

valve remains inside of the block assembly. If the

components are removed, make sure they are

installed as shown in Figure 3-12.

(f) Follow Steps (a) through (g) in reverse order to

re-assemble the new cartridge kit.

CAUTION

When connecting the cablehoz connector, be

sure to apply a high strength thread locking

adhesive compound to the threads of the brass

block assembly before threading the cablehoz

connector onto the block. This connection must

be tightened to a torque of 30-35 inch/pounds.

Failure to tighten this connection properly could

cause the power cable to overheat.