Quick robotic torch, 01 installation – Tweco Quick Robotic Torch User Manual

Page 10

3-6

Quick Robotic toRch

SM-QRTORCH

INSTALLATION AND DISASSEMBLY

SECTION 3:

INSTALLATION AND DISASSEMBLY

3.01 Installation

1. Remove the torch and cable assembly from the carton,

and lay the assembly in a straight and untwisted position

on a workbench or floor.

2. Verify that the overall cable length is correct to fit between

the feeder - robot torch mount combination.

NOTE

For cable assemblies longer than 5ft. (1,52m), it

is recommended incorporating a spring-loaded

stabilizer bar/balancer to the robot work cell to

provide support to the center of the cable assembly.

This will eliminate both excessive drooping of the

cable assembly and any interference with the

fixtures and tooling in the work area.

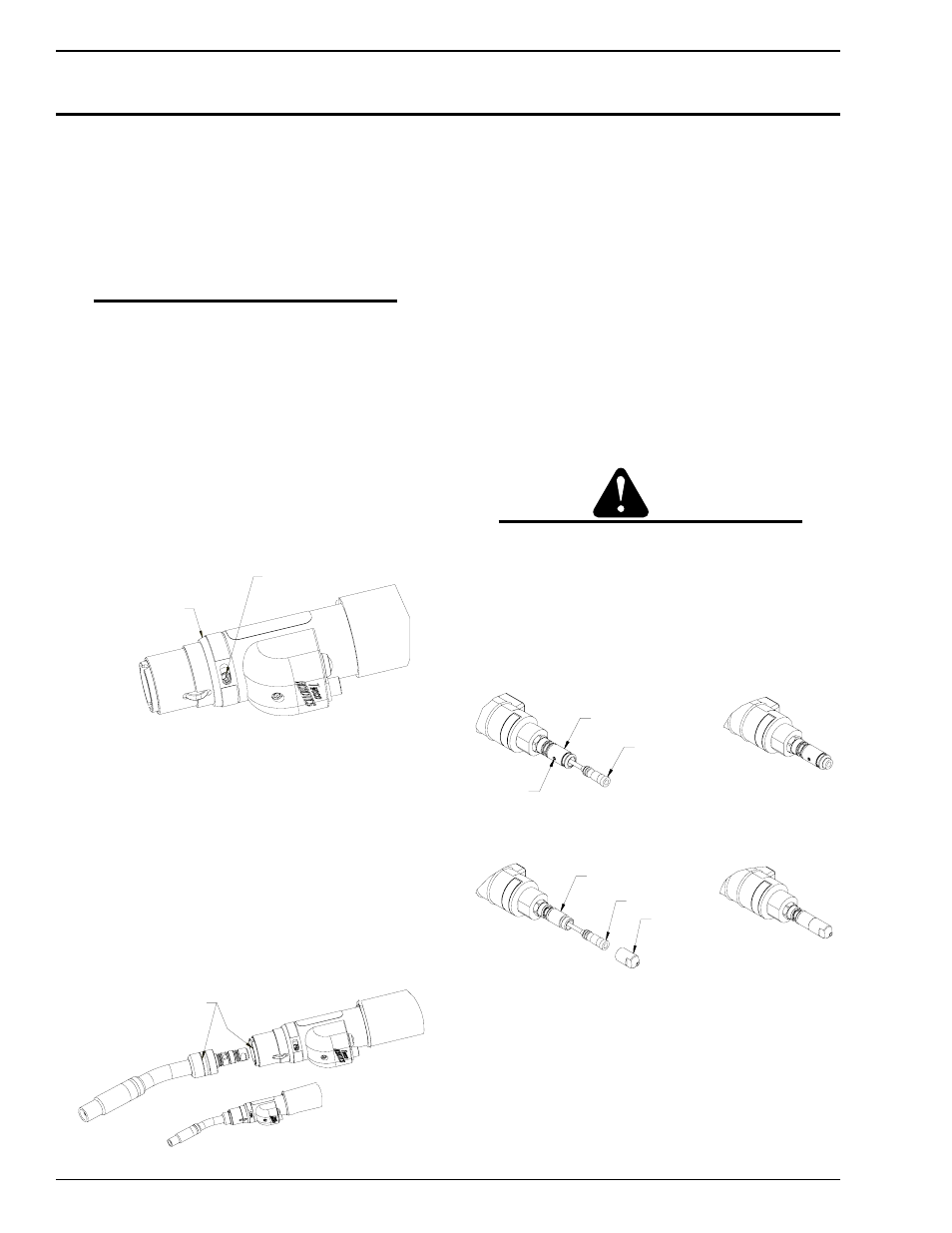

3. Rotate the front sleeve cover to expose the stainless steel

set screw located in the torch block assembly. Insert the

factory supplied 5/32” T-handle Allen wrench into the set

screw and rotate counterclockwise until it stops as shown

in Figure 3-1.

ROTATE FRONT SLEEVE COVER

TO EXPOSE SET SCREW. ROTATE

COVER TO CONCEAL SET SCREW

PRIOR TO TORCH OPERATION.

SET SCREW

(5/32" ALLEN KEY)

Art # JB-00025

Figure 3-1: Conductor Tube Locking Set Screw

4. Insert the conductor tube assembly into the torch block

assembly. The conductor tube is positively located into

the torch body by the use of two stainless steel alignment

pins.

5. Push the conductor tube assembly into place until the

stainless steel set screw can drive the back plug on the

conductor tube into its locked operating position. The

conductor tube has a machined locating groove around

its rear diameter. This groove will be flush with the front

housing when properly installed as shown in Figure 3-2.

WHEN CONDUCTOR TUBE IS FULLY SEATED,

GROOVE ON TUBE SHOULD LINE UP WITH

EDGE OF INSULATING SLEEVE.

Art # JB-00026

Figure 3-2: Conductor Tube Installation

6. Remove the gas diffuser, tip and nozzle from the conductor

tube assembly.

7. The torch and cable assembly comes with the Miller

®

rear

connector plug installed. If the feeder requires a different

rear connector plug, select the correct rear connector plug

for the feeder being used and thread the plug into the rear

of cable assembly. This connection should be wrench

tight.

8. The QR Series torch and cable assemblies are furnished

with R45-116 conduit and the rear connector plugs to

fit this series of conduit. If a different conduit and rear

connector plug is required, refer to Page 9-31 listing the

various conduits that are available.

9. Remove the conduit from the package and uncoil

carefully.

CAUTION

Bending or distorting the conduit can cause wire

feed problems.

10. Loosen the set screw located on the Tweco

®

, Panasonic

®

and Lincoln

®

rear connector plug to ensure the conduit will

feed through properly. For Miller

®

style plug, remove the

threaded connector plug nipple from the rear connector

plug on the torch assembly. Refer to Figure 3-3 & 3-4.

SET SCREW

TWECO PLUG

CONDUIT ASSEMBLY

Art # JB-00010

Figure 3-3: Conduit Installation with Set Screw

MILLER PLUG

CONDUIT ASSEMBLY

PLUG NIPPLE

Art # JB-00011

Figure 3-4: Conduit Installation with Plug Nipple (Miller

®

Style)

11. Insert the factory-supplied 5/32” T-handle Allen wrench

through the hole on the aluminum front handle cap,

identified as “Conduit Set Screw” on the label, and rotate

the set screw counterclockwise until it stops rotating.