Safety and operating instructions – Tweco Eliminator Spool Gun User Manual

Page 25

safety and operating instructions

11-21

89200011

SECTION 11:

TROUBLESHOOTING

Contact tips and nozzles should be cleaned frequently. Spatter buildup may cause bridging

between nozzle and tip. This could cause electrical shorting between the nozzle and work

piece as well as poor or improper gas flow. Regularly inspect the conductor tube, handle,

cable, and other parts of the MIG gun for abrasion, cuts, or undue wear. Replace or repair any

parts found deficient.

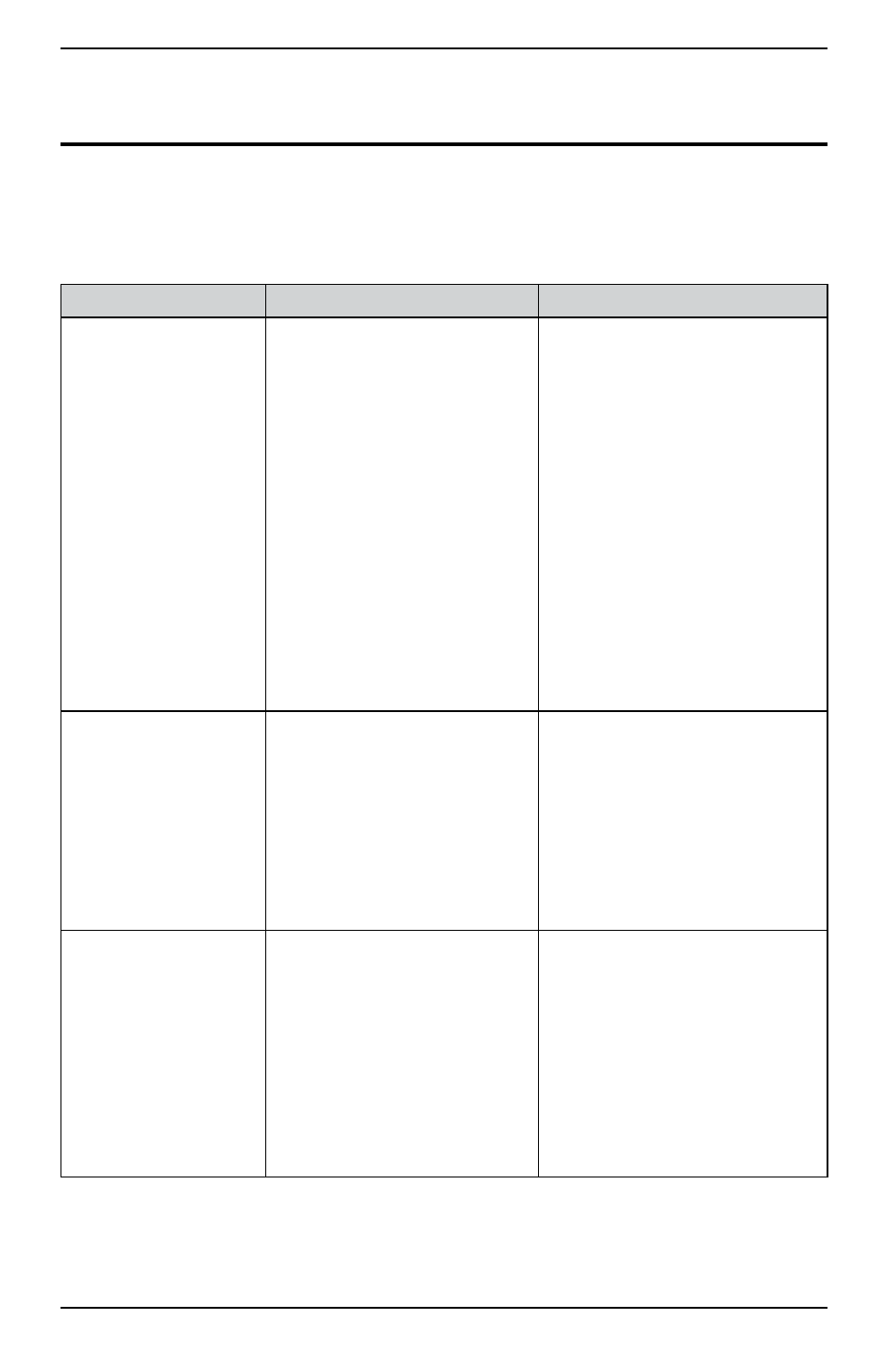

Problem

Possible Cause

Corrective Action

Wire feed inconsistent, not

smooth, or is bird nesting.

1. Loose contact tip or diffuser.

1. Tighten contact tip and diffuser

plier tight.

2. Excessively worn contact tip.

2. Replace contact tip.

3. Spatter buildup on end of

contact tip.

3. Clean or replace contact tip.

4. Sharp bends or kinks in

conduit.

4. Straighten or replace conduit.

5. Dirty or plugged conduit.

5. Replace conduit.

6. Conduit pulled back from

diffuser.

6. Reposition conduit and tighten

front set screw.

7. Machine improperly adjusted.

7. Reset machine per machine

and wire manufacturers’

recommendations.

8. Gap between drive rolls and

outlet guide inside feeder.

8. Move outlet guide right up to

drive rolls without touching and

tighten the guide nut.

MIG gun is running hot

1. Loose contact tip or diffuser.

1. Tighten contact tip and diffuser

plier tight.

2. Loose power connections.

2. Inspect complete gun for loose

connections and repair.

3. Loose or undersized ground

cable or ground clamp.

3. Tighten or replace as required.

4. Operating gun above

recommended amperage

rating.

4. Readjust machine to correct

setting for size of gun being used.

Porosity

1. Poor or improper gas flow,

possibly due to the outlet

2. Guide nut on feeder not being

tightened down on guide

1. Check gas flow out of gun nozzle.

Check for leaks or restrictions

in gas hoses and connections.

Check for O-ring damage on rear

connector plug.

2. Check outlet guide nut on feeder;

tighten if not already done.

3. Dirty or contaminated wire.

3. Change wire.

4. Base metal contaminated.

4. Replace base metal or

brush clean.

Troubleshooting