03 feedhead components, 03 feedhead components -4, Ultrafeed va 4000s – Tweco VA 4000S Ultra-Feed User Manual

Page 30

ULTRAFEED VA 4000S

OPERATION

4-4

Manual No. 0-5135

13.CAN INTERFACE PORT (J2): This connection allows

the ULTRAFEED VA 4000 S to communicate with other

select Thermal Arc power sources. This is available

with the advanced interface kit.

14.SERIAL PORT (J1): This connection allows the

ULTRAFEED VA 4000 S to communicate with a

personal computer. This feature is available with the

advanced interface kit.

15.POWER ON/OFF SWITCH: This switch controls only

the wire feeder and not the power source.

16.CIRCUIT BREAKER: This breaker protects the unit

from electrical faults.

NOTE

If the circuit breaker trips, it turns the power

switch to the OFF position. A short cooling

period must be allowed before an attempt is

made to reset the unit by pressing the circuit

breaker reset switch.

11

12

13

14

15

16

Art # A-09223

A

M

L

K

U

N

B

C

P

V

T

J

H

S

R

D

E

F

G

A

M

L

K

U

N

B

C

P

V

T

J

H

S

R

D

E

F

G

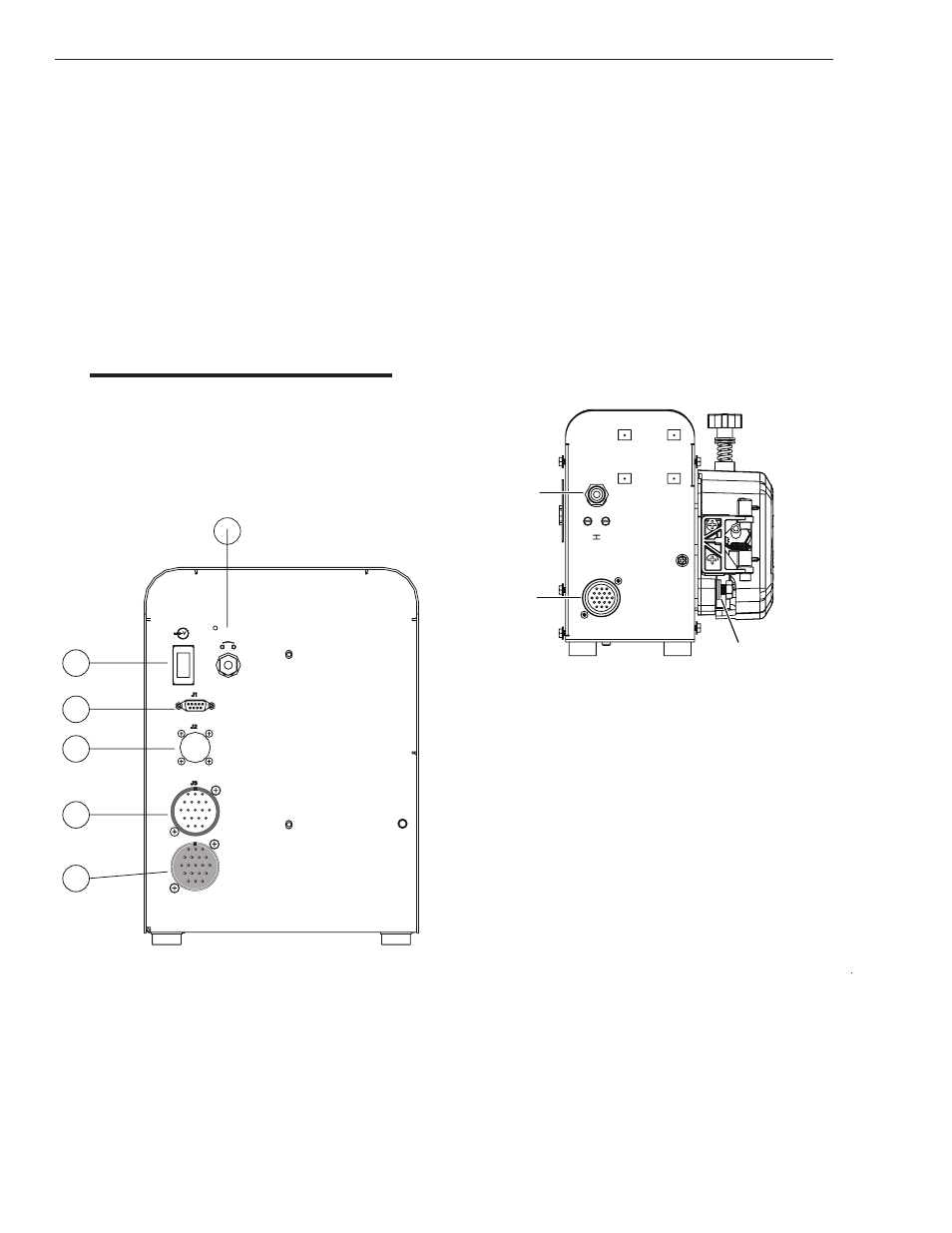

Figure 4-4: Rear Panel Controls and Connections

18.GAS VALVE INLET: This is where the shielding gas

hose is connected to the wire feeder. The gas valve

inlet controls the “on/off” flow of shielding gas through

the welding gun.

19.32' CONTROL CABLE PLUG: The 32' control cable

connects to the VA 4000 S Separation wire feeder/

motor to this 19-pin amphenol connector plug(of

which 14 pins are used). It contains the signals

required to allow the welding power source, controller

and the wire feeder to work together as a system. Refer

to Previous Chart and figure 4-2 and 4-5.

20.WELD CABLE CONNECTION: This is where the power

source welding cable is connected to the feeder. Make

sure this connection is tight or arcing could occur.

Art # A-09225

18

19

20

Figure 4-5: Separation Motor Connections

4.03 Feedhead Components

21.INPUT GUIDE LOCKSCREW: Tighten this lockscrew

to secure the input wire guide.

22.SPRING TENSION KNOB: Use the spring tension knob

to adjust the amount of force the feed rolls exert on

the welding wire.

23.FEEDROLL GEAR / KNOB : This knob is used to secure

the feedroll to the pressure arm. Rotate the knob to

change the feedroll.

24.PRESSURE ARM: This arm pivots off the front of the

feedhead to allow access to the wire guides and wire

path.

25.CENTER GUIDE LOCKSCREW: Tighten this lockscrew

to secure the center wire guide.

26.OUTPUT GUIDE LOCKSCREW: Tighten this lockscrew

to secure the output wire guide.