05 selection and installation of feed rolls, 06 welding gun compatibility and installation, Ultrafeed va 4000s – Tweco VA 4000S Ultra-Feed User Manual

Page 25

ULTRAFEED VA 4000S

Manual No. 0-5135

3-3

INSTALLATION

3.05 Selection And Installation Of Feed

Rolls

NOTE

Refer to feed roll kit drawing (supplied in the

Appendix) to order feed roll kits. Kit includes

4 drive rolls, an input wire guide, a center

guide, and an output wire guide for a specific

wire type and size.

For selection of feed roll styles, refer to Feedroll Drive Kit

Drawing 171435 and Feedroll Chart 375980 in the

Appendix section of this manual.

Style 1: Feed rolls consist of flat smooth top rolls and

double smooth, vee grooved bottom rolls. They feed .024

- .068" hard and tubular wire.

Style 2: Feed rolls consist of flat knurled top rolls and a

double smooth, vee grooved bottom rolls. They feed .030

- .045" hard and tubular wire.

Style 3: Feed rolls consist of double smooth, vee grooved

drive rolls. This style supports 0.035 to 1/16” soft wire.

Style 4: Feed rolls consist of double knurled, vee grooved

grooved drive rolls. They feed .045 - 5/64" hard and tubular

wire.

Style 5: Feed rolls consist of double cog top and bottom

rolls. They feed .045 - 1/8" tubular wire.

Style 6: Feed rolls consist of double U-grooved top and

bottom feed rolls. They feed .035 - 1/16" soft wire.

NOTE

All grooved feed rolls have their wire size or

range stamped on the side of the roll. On rolls

with different size grooves, the outer (visible

when installed) stamped wire size indicates

the groove in use.

Feed rolls are removed by twisting the feed roll retainer

cap and aligning the retaining knob splines with the drive

gear splines. Feedrolls are installed by putting the feedroll

onto the drive gear splines and twisting the feedroll

retainer cap so that the splines rest against the face of

the feedroll.

NOTE

Installation of all styles of feed rolls for this

feeder is identical.

3.06 Welding Gun Compatibility And

Installation

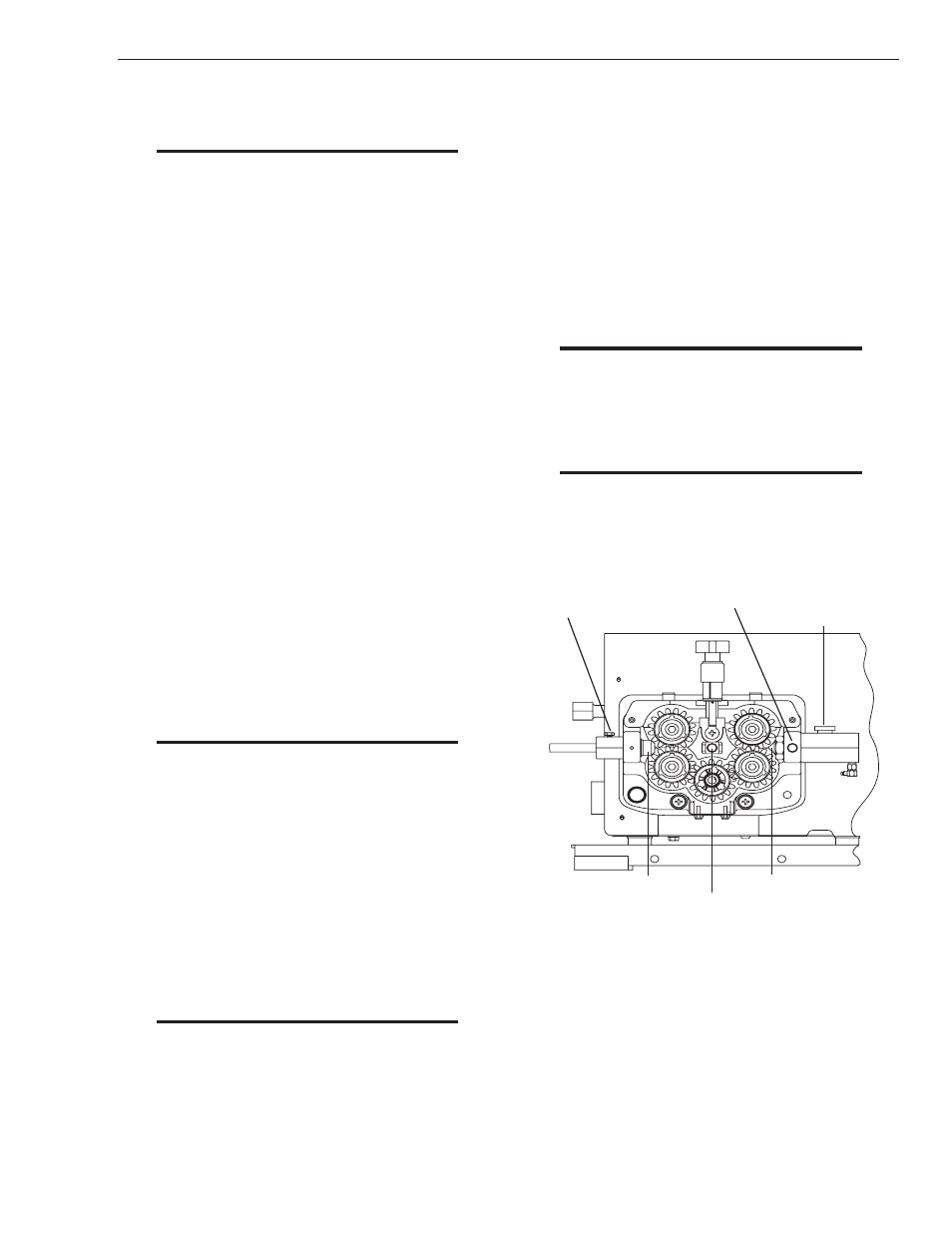

Refer to Figure 3-2.

The Ultrafeed VA 4000 S Separation Unit wire feeder is

designed to be used with most welding guns. In some

cases, a special adapter may be required.

To install the welding gun, simply loosen the gun clamp

knob and insert the welding gun into the feedhead until it

stops. Tighten the gun clamp knob and connect the

welding gun control wires to the gun switch receptacle.

NOTE

Before inserting the welding gun into the

feedhead, make sure the gun clamp does not

extend into the feedhead; otherwise, the

welding gun cannot be properly inserted.

NOTE

Check for gas leaks. If leaking gas, gun is not

all the way into the feedhead.

Art # A-04326

Output Wire Guide

Input Guide Lockscrew

Input Wire Guide

Output Guide

Lockscrew

Gun Clamp

Knob

Center Wire Guide

Figure 3-2: Welding Gun Installation