Tweco HMC-410 Robotic Interface Kit User Manual

Page 25

Postflow Time:

.7 Seconds

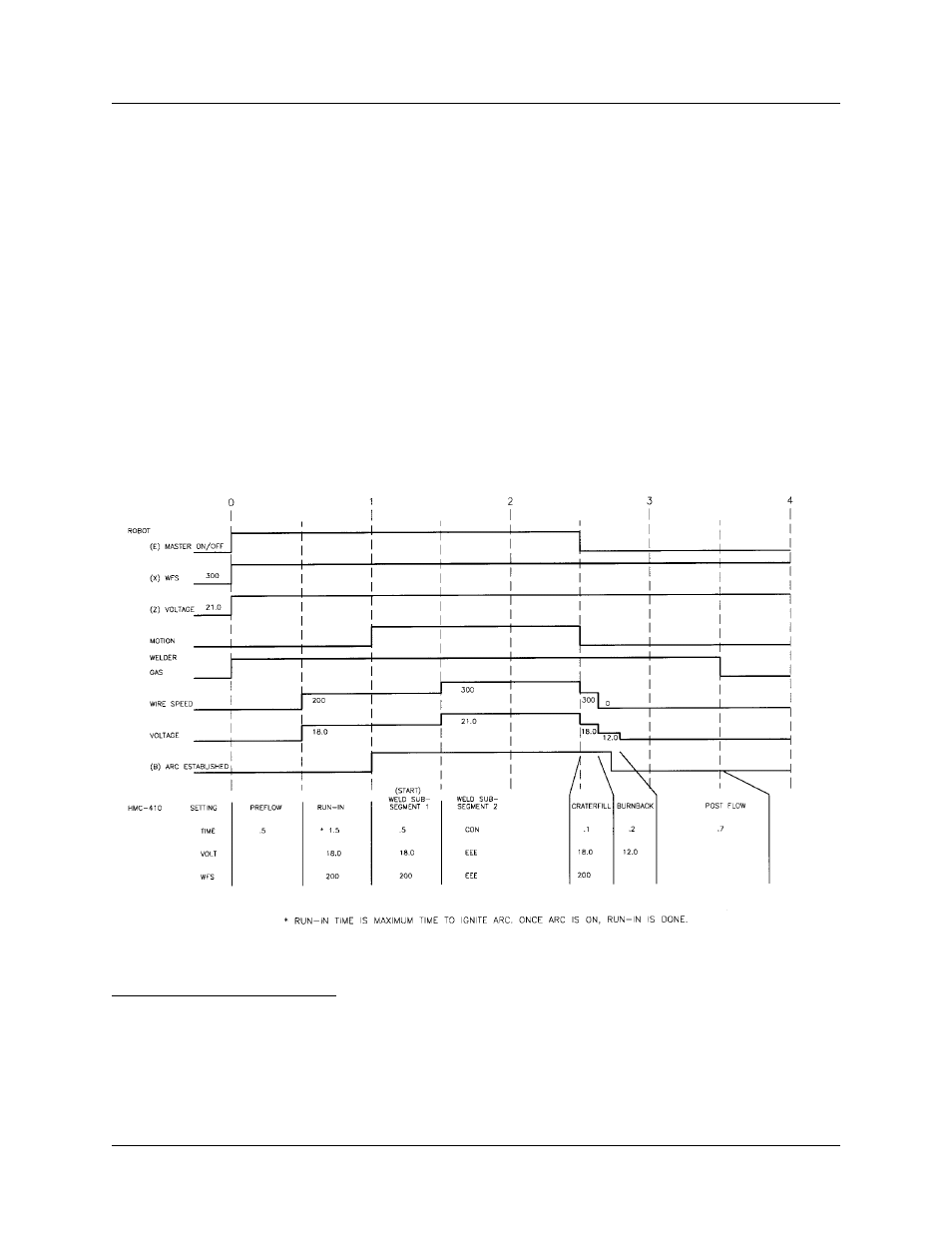

The way that these settings interact with the robot is shown in Figure 5.

Once the torch is positioned over the weld location, the robot initiates the arc with the Master Weld On/Off

signal. At that point, the HMC-410 pre-purges the gas for 1/2 second, then initiates the arc with the settings

for the runin segment. Once an arc is struck, the welding parameters change to the weld sub-segment 1 pa-

rameters (weld start parameters), while simultaneously signaling the robot that an arc is established with

the arc established signal. At that point, the robot will begin to move. After ½ second in this example, the

start parameters expire and the control transitions the weld to the main weld parameters set by the robot

control. Once the robot has completed its seam, the robot stops the weld by removing the Master Weld

On/Off control signal. At that point, the HMC-410 transitions to the craterfill segment (.1 second for this ex-

ample), then treats the wire during the burnback segment, and finishes with .7 seconds of postflow.

Wire Stick Enable (ELS):

This softswitch enables the check for a wire stuck to the work. This feature only works with the

Power-Master or Arc-Master family of power sources; or other appropriately modified power sources. To

function, the 870210 board supplied with this kit should be installed. See the installation section of this

manual for more details on installing.

When this board is installed, the power source will have between 10 and 17 VDC present on its output ter-

minals when it’s not welding. This is a low power sensing voltage and will not cause any arcing when the

wire touches the work.

430429-457

June 13, 2002

2-19

Figure 5 Example Timing Diagram

2

The weld sub-segments are segmented parts of the main weld. A typical use is shown here where the welder

may want a different setting for the beginning of the weld. This is effectively a start weld level. There are up

to 4 sub-segments, so it is possible that there could be 3 start levels to precisely set the starting profile of the

weld, while maintaining the last sub-segment as the main weld segment. This feature is also explained the in

HMC-410 Owner’s Manual.