Tweco 180 Portable MIG User Manual

Page 54

FABRICATOR 140, 180

MAINTENANCE

Manual 0-4991

5-4

July 20, 2007

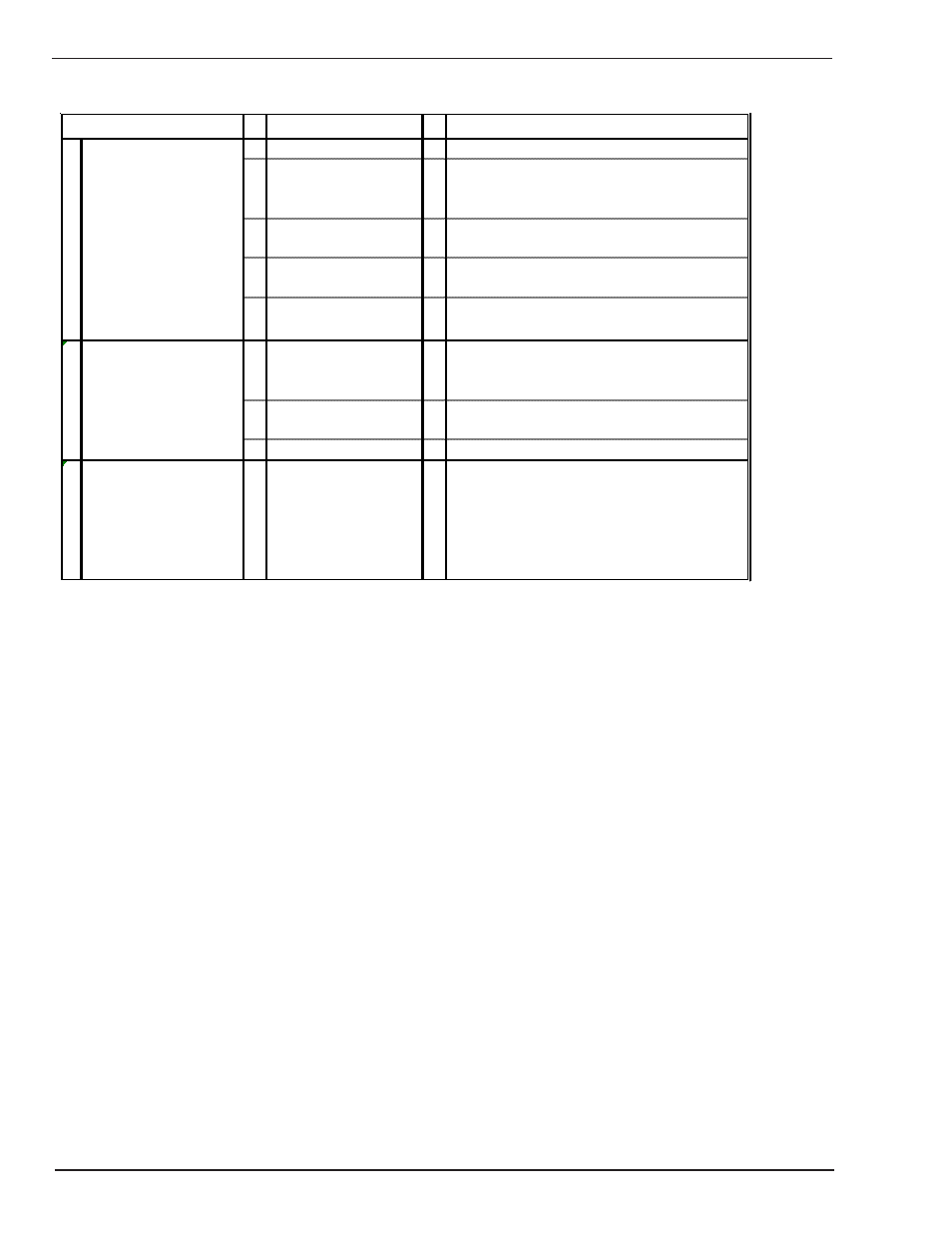

FAULT

CAUSE

REMEDY

6 Weld cracking

A Weld beads too small

A Decrease travel speed

B Weld penetration

narrow and deep

B Reduce current and voltage and increase MIG

torch travel speed or select a lower penetration

shielding gas.

C Excessive weld

stresses

C Increase weld metal strength or revise design

D Excessive voltage

D Decrease voltage by reducing the voltage

selection switch.

E Cooling rate too fast

E Slow the cooling rate by preheating part to be

welded or cool slowly.

7 Cold weld puddle

A Faulty rectifier unit

A Have an Accredited THERMAL ARC Service

Agent to test then replace the faulty

component.

B Loose welding cable

connection.

B Check all welding cable connections.

C Low Primary Voltage

C Contact supply authority

8 Arc does not have a crisp

sound that short arc

exhibits when the

wirefeed speed and

voltage are adjusted

correctly.

The MIG torch has been

connected to the wrong

voltage polarity on the

front panel.

Connect the MIG torch to the positive (+)

welding terminal for solid wires and gas

shielded flux cored wires. Refer to the electrode

wire manufacturer for the correct polarity.

Table 5-1b: Welding Problems Continued