12 reference tables, 12 reference tables -9 – Tweco 180 Portable MIG User Manual

Page 45

OPERATION

FABRICATOR 140, 180

July 20, 2007

4-9

Manual 0-4991

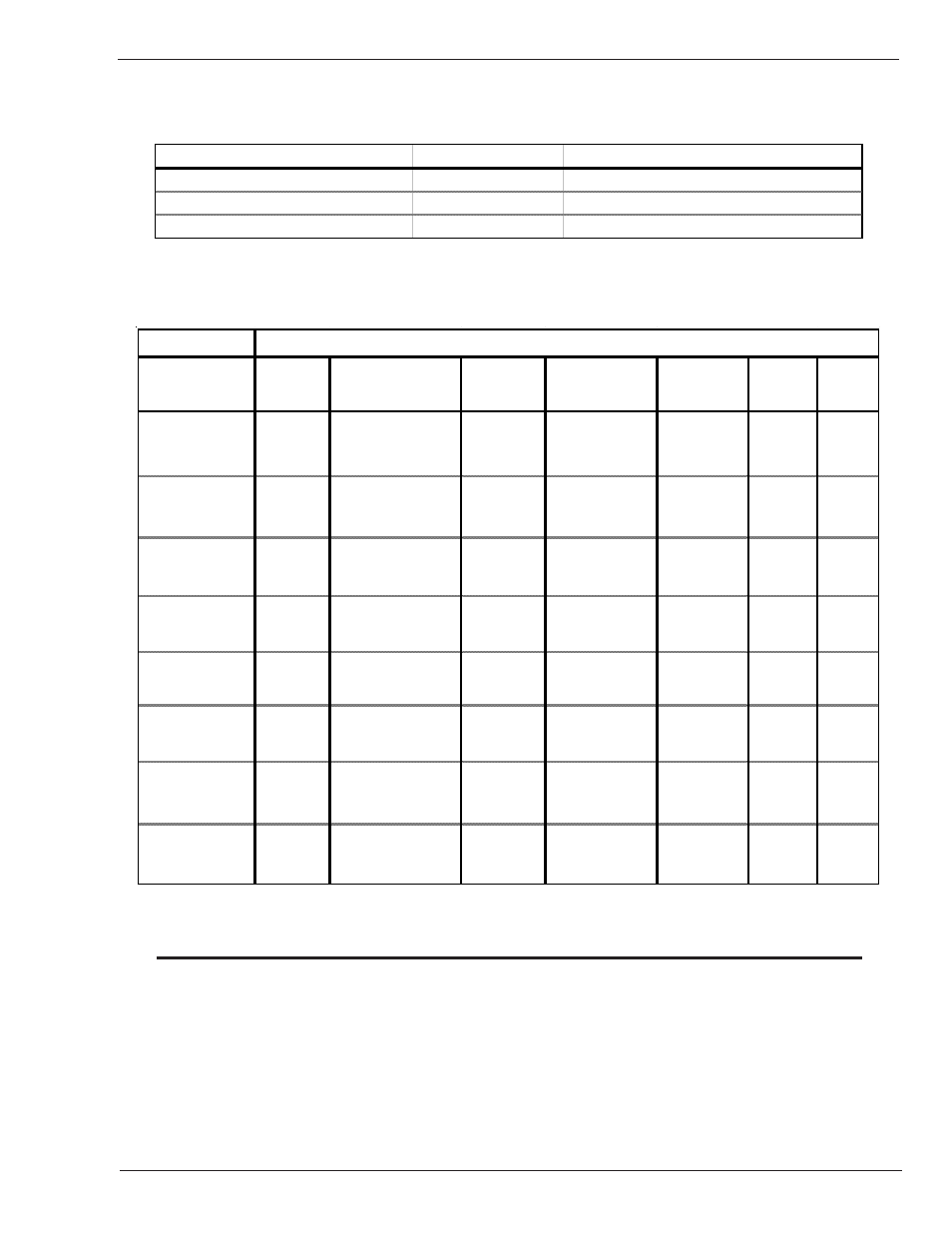

4.12 Reference Tables

The following tables are provided as user aids when performing MIG or FLUX CORED welding.

Type of Gas

Typical Mixtures

Primary Uses

Carbon Dioxide (CO2)

Mild and low alloy steels

Argon (Ar) - Carbon Dioxide (CO2) 75% Ar – 25% CO2 Mild and low alloy steels, Stainless Steel

Argon (Ar)

Aluminum

Result Desired

Arc

Voltage

Welding Current

(wire speed)

Travel

Speed

Nozzle Angle Stick out

Wire

size

Gas

Type

Deeper

Penetration

1

Increase

3

Trailing Max

25°

2

Decrease

5

Smaller

(*)

4

CO

2

Shallower

Penetration

1

Decrease

3

Leading

2

Increase

5

Larger

4

Ar CO

2

mix

Larger Bead

1

Increase

2

Decrease

3

Increase

(*)

Smaller Bead

2

Decrease

2

Increase

3

Decrease

(*)

Higher

Narrower Bead

1

Decrease

2

Trailing

3

Increase

Flatter Wider

Bead

1

Increase

2

90° or

Leading

3

Decrease

Faster

Deposition Rate

1

Increase

2

Increase

(*)

3

Smaller

Slower

Deposition Rate

1

Decrease

2

Decrease

(*)

3

Larger

Welding Variable

Key: (1) First Choice, (2) Second Choice, (3) Third Choice, (4) Fourth Choice, (5) Fifth Choice

NOTE

Same adjustment is required for wire feed speed.

* When these variables are changed, the wire feed speed must be adjusted so that the welding current remains

constant. See DEPOSITION RATE in the WELDING VARIABLES section. This change is especially helpful on materials

of 20 gauge (.04” 1mm approximately) and smaller in thickness.