05 welding problems, 05 welding problems -3 – Tweco 180 Portable MIG User Manual

Page 53

MAINTENANCE

FABRICATOR 140, 180

July 20, 2007

5-3

Manual 0-4991

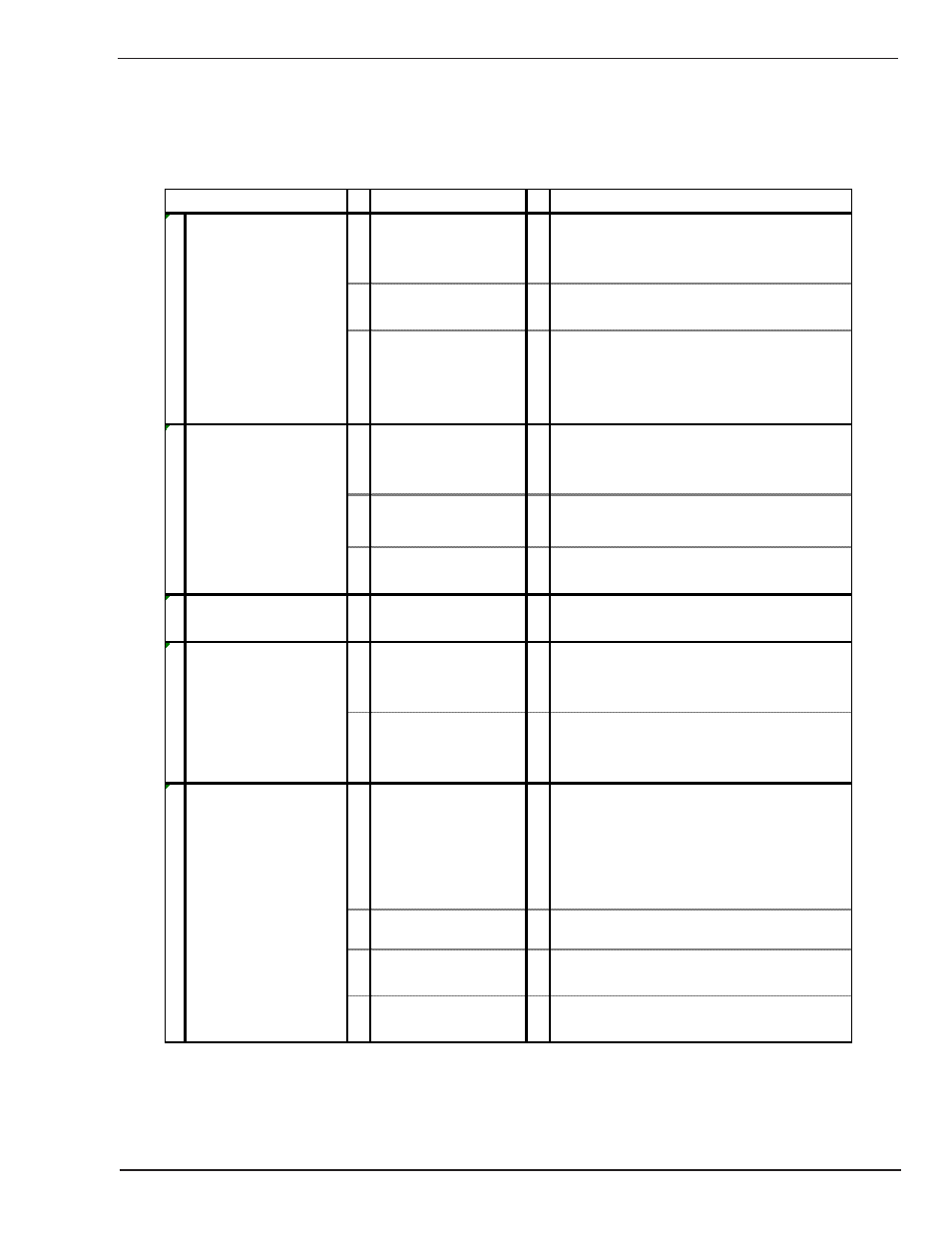

5.05 Welding Problems

FAULT

CAUSE

REMEDY

1 Undercut.

A Welding arc voltage

too high.

A Reduce voltage by reducing the voltage

selection switch position or increase the

wire feed speed.

B Incorrect torch

angle

B Adjust angle

C Excessive heat input C Increase the torch travel speed and/or

reduce welding current by reducing the

voltage selection switch position or

reducing the wire feed speed.

2 Lack of penetration. A Welding current too

low

A Increase welding current by increasing

wire feed speed and increasing voltage

selection switch position.

B Joint preparation

too narrow or gap

i h

B Increase joint angle or gap

C Shielding gas

incorrect

C Change to a gas which gives higher

penetration

3 Lack of fusion.

Voltage too low

Increase voltage by increasing voltage

selection switch position.

4 Excessive spatter.

A Voltage too high

A Lower voltage by reducing the voltage

selection switch or increase wirespeed

control.

B Voltage too low

B Raise voltage by increasing the voltage

selection switch or reduce wirespeed

control.

5 Irregular weld shape. A Incorrect voltage

and current settings.

Convex = voltage too

low. Concave =

voltage too high.

A Adjust voltage and current by adjusting

the voltage selection switch and the

wirespeed control.

B Wire is wandering

B Replace contact tip

C Incorrect shielding

gas

C Check shielding gas

D Insufficient or

excessive heat input

D Adjust the wirespeed control or the

voltage selection switch

Table 5-1a: Welding Problems