Arcmaster, 300 s – Tweco 300 S Arcmaster User Manual

Page 31

ARCMASTER

®

300 S

March 31, 2006

6-1

SECTION 6:

SEQUENCE OF OPERATION

NOTE: Scroll Buttons are used to select the parameters to be set. The LED’s show which function

is being adjusted on the weld sequence graph. Refer to Symbols Table located in the front of the

manual for Symbol descriptions.

1

2

3

4

5

6

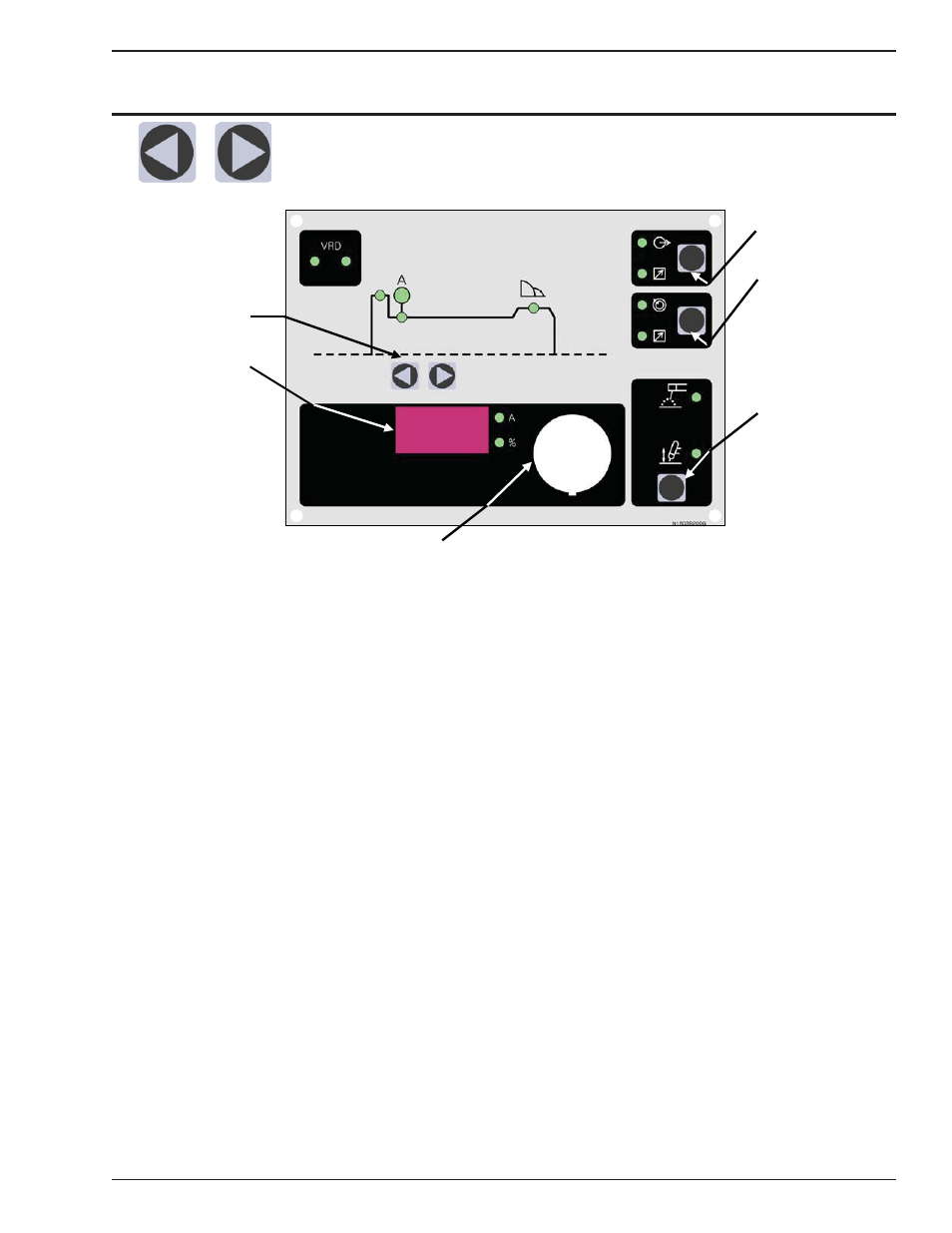

Figure 7 – 300 S Front Panel

1. Scroll Buttons – used to select the parameter to be set.

The LED’s show which function is being adjusted on the

Sequence Graph.

2. Digital LED display – Welding amperage and parameter

values are displayed in this window. Internal warnings

such as over temperature, low or high input voltage

applied are signaled to the operator by a warning sound

and error message on the screen.

3. Control knob – allows the operator to adjust the output

amperage within the entire range of the power source,

also used to set each parameter value.

4. Process Button – This button selects between STICK or

Lift TIG mode.

5. Contactor function – Pressing this buttons enables

Contactor functions.

6. Remote Current function – Pressing this buttons enables

remote current functions.

6.01 Stick Welding

• Connect work lead to negative terminal

• Connect electrode lead to positive terminal

• Switch machine on

• Set Contactor

• Connect remote control device if required

Use the Scroll Buttons to move to the parameter to be set.

The LED will show which function is being adjusted on the

weld sequence graph. Use the control knob to adjust each

parameter.

• Set HOT START

• Set WELD current

• Set Arc Control

Commence welding

6.02 DC LIFT TIG Welding

• Connect work lead to positive terminal

• Connect TIG torch to negative terminal

• Switch machine on

• Set weld current.

• Connect remote control device if desired

Use the Scroll Buttons to move to the parameter to be set.

The LED will show which function is being adjusted on the

weld sequence graph. Use the control knob to adjust each

parameter.

• Set WELD current

Commence welding