13 dpc-3000 status codes, 13 dpc-3000 status codes -21, Ultra-cut 200 – Tweco 200 Ultra-Cut(March 2013) User Manual

Page 93

Manual No. 0-5133

4-21

OPERATION

ULTRA-CUT 200

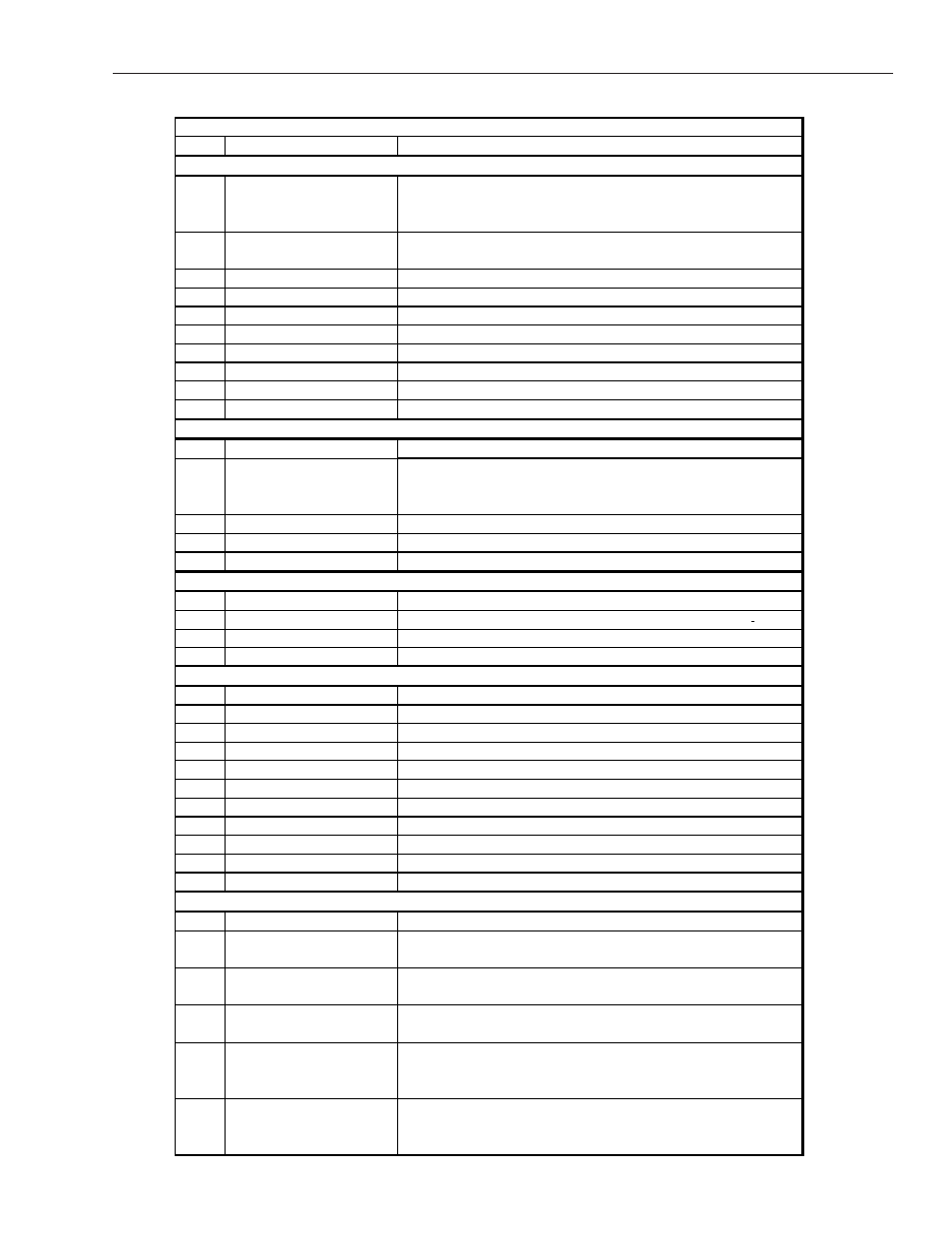

4.13 DPC-3000 Status Codes

Code Message

Cause/Remedy

1-1

Plasma Disabled

Enable Plasma; DMC Power Supply input fuse F1 blown (no lights on

DMC); Defective DMC Power Supply (E-Stop relay). Defective DPC

Power Supply (E-Stop relay). Defective DPC control PCB

1-2

24 VDC fault

Check /replace DPC power supply output fuse (F2); Defective DPC

power supply; Replace DPC control PCB

1-3

+12 VDC fault

Check /replace DPC power supply; Replace DPC control PCB

1-4

-12 VDC fault

Check /replace DPC power supply; Replace DPC control PCB

1-5

5 VDC fault

Check /replace DPC power supply; Replace DPC control PCB

1-6

Analog Reference fault

Replace DPC Control PCB

1-7

ADC voltage fault

Replace DPC Control PCB

1-8

Reserved

1-9

Valve not configured

Resend process from TSC 3000 / CNC

1-10

DPC is locked

Process loading, wait until finished

2-1

Acknowledge error

Fiber optic cable; DPC Control PCB

2-2

Timeout

Communication loss: Check DMC codes; if DMC 2-1 check DPC to

DMC Fiber optic cable, DMC 4-2 check DMC to CCM fiber-optic cable.;

DPC Control PCB; DMC Control PCB; CCM.

2-3

Protocol

Program firmware fault, consult factory

2-4

Bus off

Fiber optic cable; DPC Control PCB

2-5

Physical

Fiber optic cable; DPC Control PCB

3-1

Plasma Gas High (>145 PSI) Reduce pressure from gas supply; defective pressure sensor (PS4).

3-2

Pilot Gas High (>145 PSI)

Reduce pressure from gas supply; defective pressure sensor (PS3).

3-3

Shield Gas High (>145 PSI)

Reduce pressure from gas supply; defective pressure sensor (PS1).

3-4

Shield H2O High (>145 PSI) Reduce pressure from gas supply; defective pressure sensor (PS2).

4-1

Plasma High (V5) shorted

Check for shorted wire harness; Replace valve

4-2

Plasma Low (V4) shorted

Check for shorted wire harness; Replace valve

4-3

Pilot (V3) shorted

Check for shorted wire harness; Replace valve

4-4

Shield Gas (V1) shorted

Check for shorted wire harness; Replace valve

4-5

Shield H2O (V2) shorted

Check for shorted wire harness; Replace valve

4-6

Vent (SOL2) shorted

Check for shorted wire harness; Replace valve

4-7

Cut (SOL3) shorted

Check for shorted wire harness; Replace valve

4-8

Mark (SOL1) shorted

Check for shorted wire harness; Replace valve

4-9

Vent (SOL2) open

Check for open connection; Replace valve.

4-10

Cut (SOL3) open

Check for open connection; Replace valve.

4-11

Mark (SOL1) open

Check for open connection; Replace valve.

5-1

Valve open

Check for open connection; Replace valve.

5-2

DPC inlet Supply pressure

low

Raise plasma inlet pressure; check for DMC valve not open;

restriction in gas supply / hoses.

5-3

Outlet pressure too low

Valve full open. Leak in plasma hose to torch; defective control valve

(V5); defective pressure sensor (PS6); DPC Control PCB

5-4

Outlet pressure low

Tracking error Leak in plasma hose to torch; defective control valve

(V5); defective pressure sensor (PS6); DPC Control PCB

5-5

Outlet pressure too high.

Valve at minimun setting. Restriction in plasma hose, torch, DPC

manifold; defective control valve (V5); defective pressure sensor

(PS6); DPC Control PCB

5-6

Outlet pressure high.

Tracking error. Restriction in plasma hose, torch, DPC manifold;

defective control valve (V5); defective pressure sensor (PS6); DPC

Control PCB

Group 4 - Proportional Valves & Solenoids Electrical Faults

Group 5 - Plasma High Proportional Valve (V5)

DPC Status Code Key

Group 1 - DPC

Group 2 - Control Communication

Group 3 - Inlet Pressure Faults