A7.02 nc input / output descriptions, Ultra-cut 200, A7.02 cnc input / output descriptions – Tweco 200 Ultra-Cut(March 2013) User Manual

Page 143

Manual 0-5133

A-9

APPENDIX

ULTRA-CUT 200

Function

Connection

OK to Move (Contacts or DC Volts)

TB2-10(-); TB2-12(+)

Plasma Marking Remote Select

TB3-1: TB3-2

A7.02

CNC Input / Output Descriptions

E-Stop input— Requires closed connection rated for

35ma. @ 20VDC

for unit to operate. Factory installed jumper between

TB1-1&2 must be removing when connecting user supplied E-Stop circuit.

4

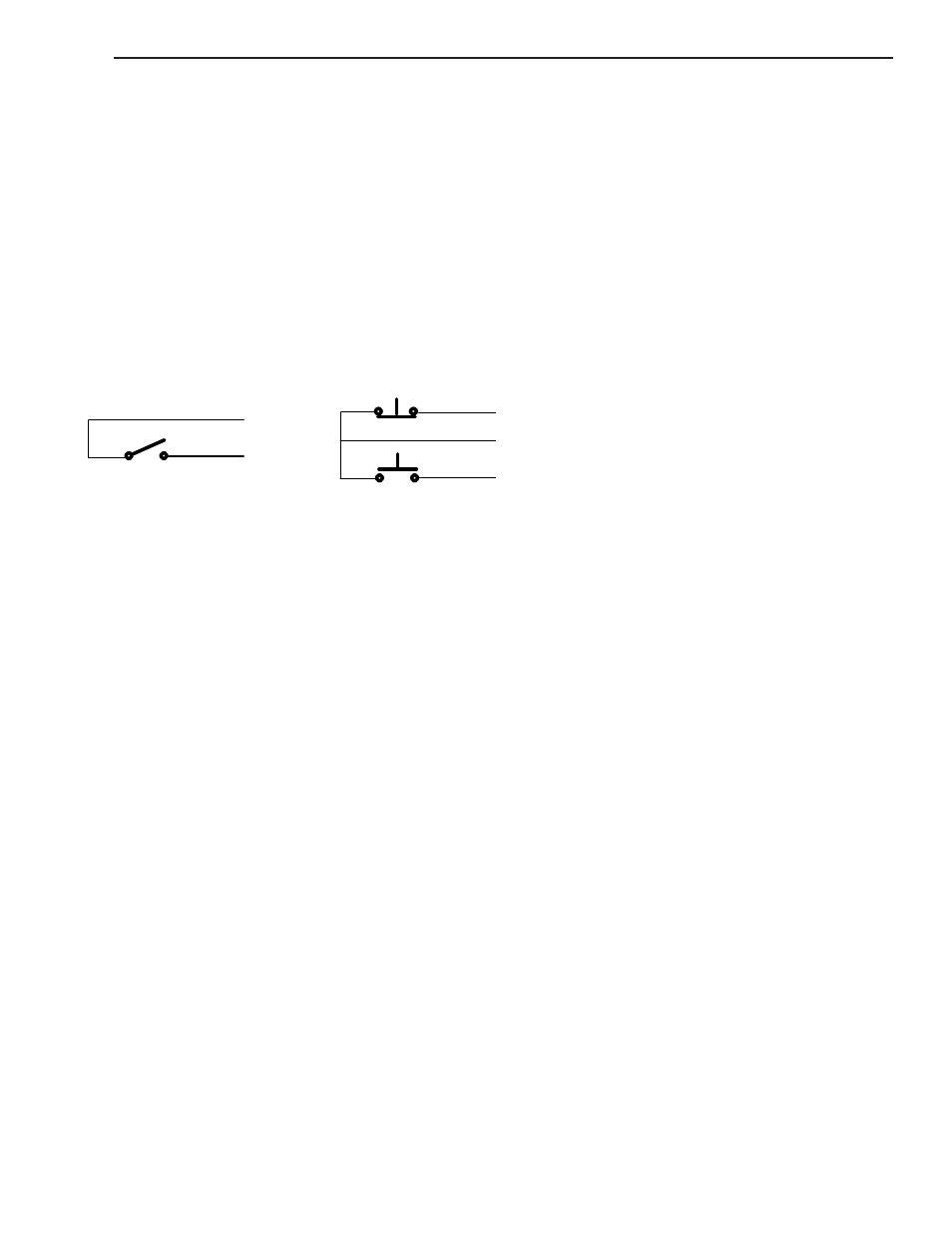

Start/Stop input—Switch (momentary or sustained) rating 35ma. @ 20 VDC

Start / Stop circuit configurations. Momentary Start / Stop (Latched) is only available at TB1.

MOMENTARY START / STOP

START / STOP

TB1-6

TB1-5

TB1-4

SUSTAINED START / STOP

START

STOP

TB1-5

TB1-6

Divided Arc Voltage output

— Arc Voltage signal is isolated from plasma supply, however (-) is common with other

isolated CNC signals. Max Divided Arc Voltage signal level depends on actual arc voltage times divide ratio however

can not exceed approximately 12 V.

3

Analog Current Control input

— Analog Current Control includes analog isolation module, separate isolation

module not usually required however it’s low input is common with the other isolated CNC inputs. Scaling of Analog

Current Control input is 0V = 0A, 10V. = MAX output and is linear in between. However MIN output is 10A. User is

responsible for setting correct analog voltage to maintain at least 10A output. To use Analog Current Control on the

I/O PCB set SW 11 to down position and on the CPU PCB set SW8-2 ON (up).

Hold Start input

—Normally open, close to hold start. Circuit rating 10 ma. @ 20VDC. Delays pilot ignition, gas

preflow continues. Used for synchronizing starts when multiple plasma supplies are used on same cutting table. User

supplies circuit to keep Hold Start inputs active until all torches have found height.

Preflow On input

— Normally open, close to start preflow prior to normal START signal. Circuit rating 10 ma. @

20VDC. Torch Height Controls (THC) normally issue START signal to plasma supply after torch height has been

found. Then the plasma takes 1-2 seconds (or more) to perform preflow before igniting pilot. Some THCs have an

output that can start preflow early during height finding saving 1-2 seconds on each cut.

Pilot On output

– Relay contacts rated 1A @ 120 VAC / 28 VDC. Contacts close when pilot on. Can be wired parallel

with Ok to Move contacts to start machine motion when pilot established. Used when starting over holes. Starting over

holes requires setting SW8-1 ON (up) on the CPU PCB for extended pilot time. Using extended pilot time to start over

holes or for cutting over holes will reduce parts life.

OK to Move output

— Active when cutting arc is established, arc is transferred. Used to signal cutting table to start

X-Y motion. Relay contacts rated 1A @ 120 VAC or 28 VDC when SW6 set for contacts. When SW6 is set for DCV, output

supplies 15-18 VDC @ 100 ma. May be wired parallel with Pilot On to start cutting machine motion as soon as pilot

established.

5

The following features are available in Ultracut CCM revision level BA and higher or S/N

05517201 and higher.

5

OK to Move2

– Provides a second set of N.O. contacts that close when arc transfer is detected. Contacts are rated for

maximum of 24 VAC/DC @ 1A.