03 sequence of operation, Cutmaster 42 – Tweco 42 CutMaster Operating Manual User Manual

Page 20

CUTMASTER 42

CUTMASTER 42

OPERATION 4-4 Manual 0-5141

Manual 0-5141 4-5 OPERATION

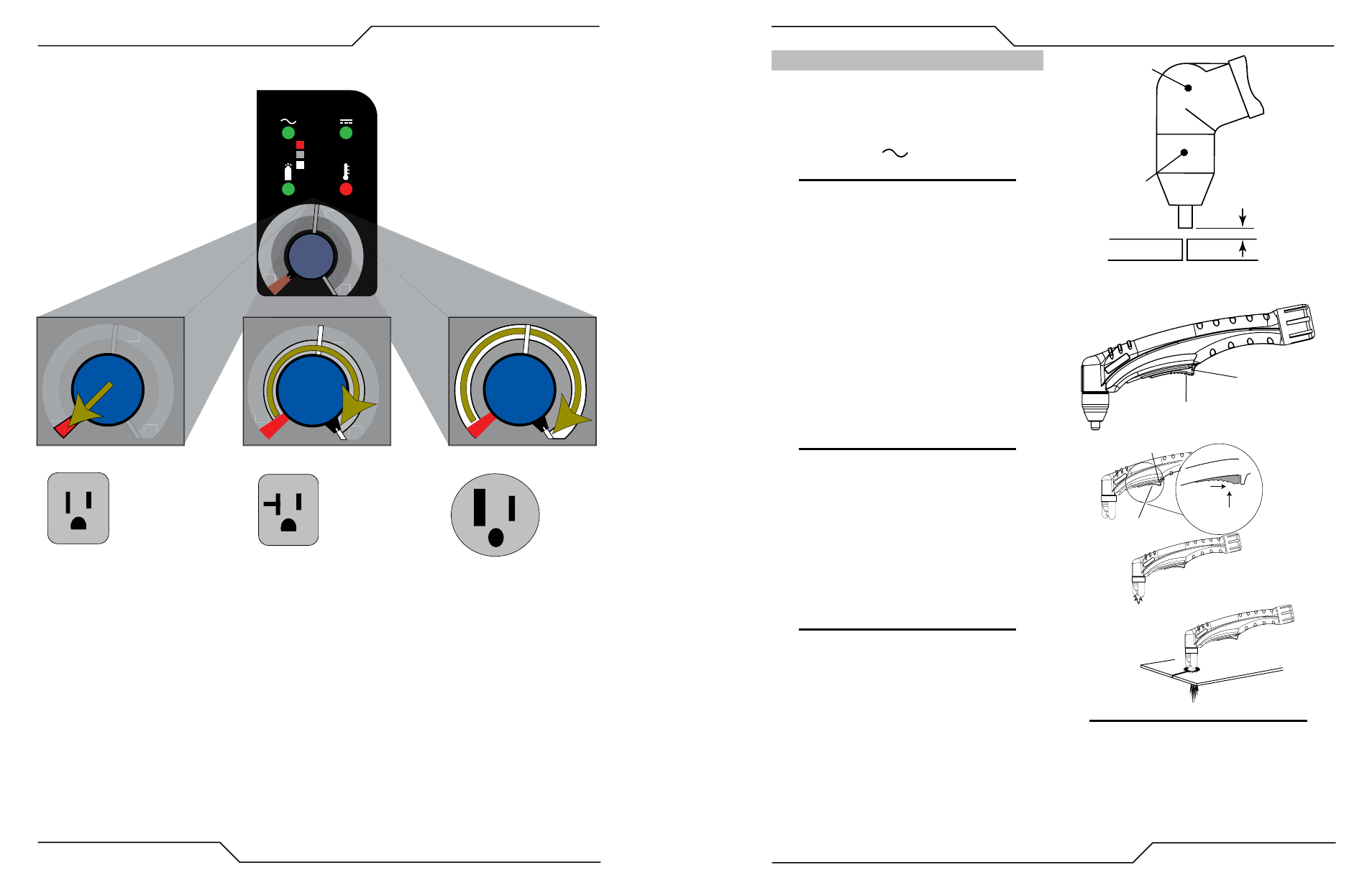

G. Select Current Output Level

Set the desired current output level.

A

120V 15A

120V 20A

230V 20A

24

40

20

20

30

27

120V, 15A

24

40

20

20

30

27

24

40

440

20

20

30

7

277

00

230V, 20A

24

20

27

24

20

7

27

40

20

30

A

4

30

120V, 20A

40

20

30

30

30

30

A

24

40

440

20

20

7

277

A

24

2

A

4

22

0

40

20

30

24

20

A

A

A

27

A#09697_AA

4.03 Sequence of Operation

The following is a typical sequence of operation for this

power supply.

1. Place the ON / OFF switch on the power supply to ON

(up) position (Red indicator lamp is illuminated).

a. AC indicator

turns on; fan turns on.

NOTE

During initial power up, there will be a delay

of about 2 seconds before the AC Indicator

light will illuminate and the pre-flow gas and

fan starts. The gas will automatically flow

from torch for approximately 10 seconds

(only after the AC Indicator lamp is illu-

minated) (The AC Indicator lamp and fan

turns on approximately 2 seconds after the

ON/OFF switch is enabled), this is a pro-

cess that makes sure all inputs (gas, input

power, torch connection, and torch parts)

are acknowledged for proper operation.

2. Wear protective clothing, including welding gloves and

appropriate eye protection (see table 1-1). Place tip on

work piece and pull trigger. Arc will initiate and start

cutting material.

Standoff Cutting With Hand Torch

NOTE

For best performance and parts life, always

use the correct parts for the type of opera-

tion.

A. The torch can be comfortably held in one hand

or steadied with two hands. Position the hand to

press the Trigger on the torch handle. With the

hand torch, the hand may be positioned close to

the torch head for maximum control or near the

back end for maximum heat protection. Choose

the holding technique that feels most comfortable

and allows good control and movement.

NOTE

The tip should never come in contact with

the workpiece except during drag cutting

operations.

B. Depending on the cutting operation, do one of the

following:

a) For drag cutting, place the tip on the plate

holding the torch at a angle to the plate so that

only one edge of the tip is in contact with the

plate. This prevents damage to the tip during

the piercing process.

b) For standoff cutting, hold the torch tip on the

work piece, pull the trigger. After the arc is

initiated lift the tip to 1/8" - 3/8" (3-4mm) off

the work.

A-00024_AB

Shield Cup

Torch

Standoff Distance

1/8" - 3/8" (3 - 9mm)

Standoff Distance

Art # A-09342

Trigger

Trigger Release

3

4

Trigger

2

1

Trigger Release

Art # A-11462

NOTE

When the shield cup is properly installed,

there is a slight gap between the shield cup

and the torch handle. Gas vents through

this gap as part of normal operation. Do

not attempt to force the shield cup to close

this gap. Forcing the shield cup against

the torch head or torch handle can damage

components.