Cutmaster 12mm – Tweco CutMaster 12mm User Manual

Page 35

CUTMASTER 12mm

Manual 0-5076

OPERATION

4T-3

and can be easily scraped off. "High speed dross" usually

forms a narrow bead along the bottom of the cut edge and

is very difficult to remove. When cutting a troublesome

steel, it is sometimes useful to reduce the cutting speed

to produce "slow speed dross". Any resultant cleanup can

be accomplished by scraping, not grinding.

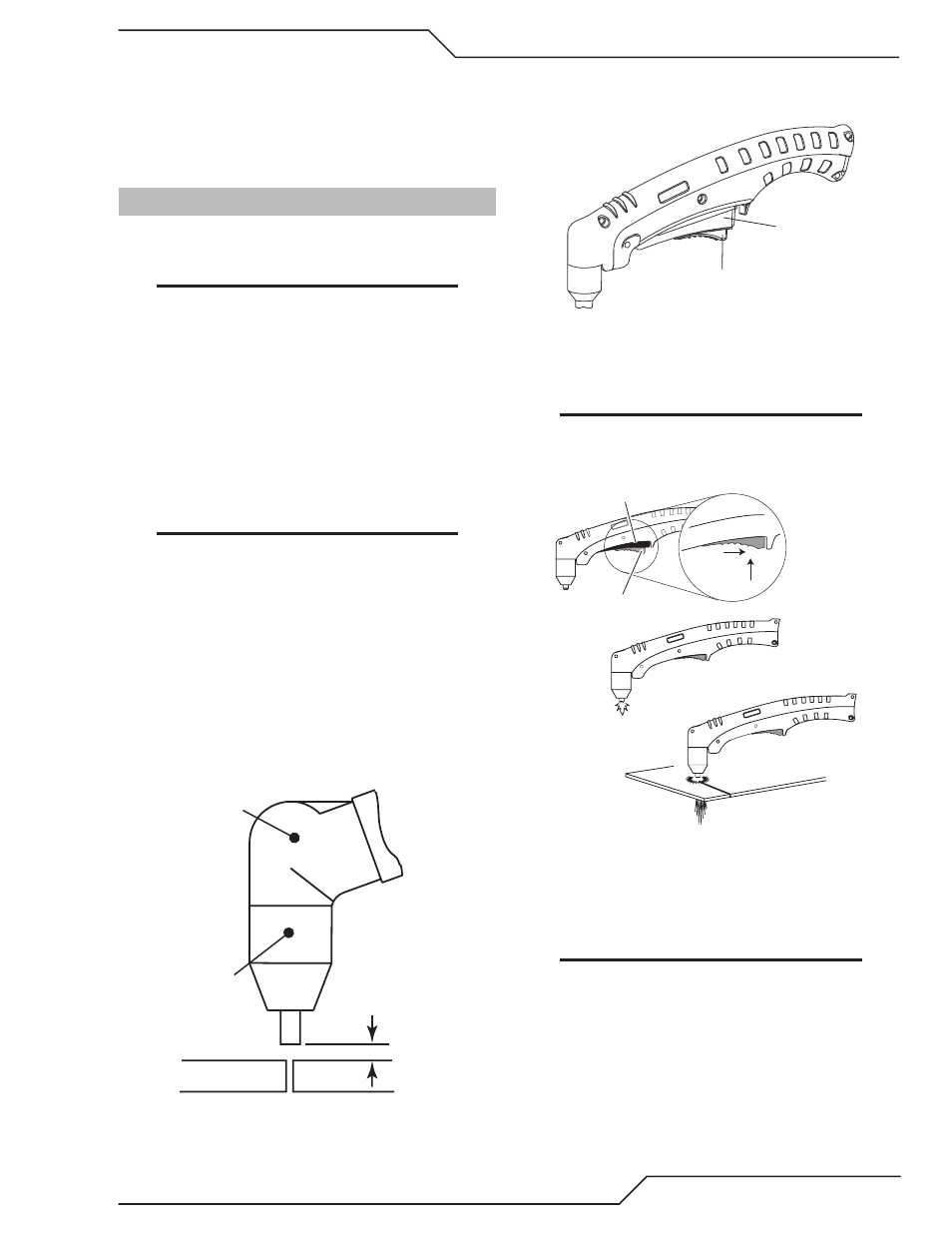

4T.04 Hand Torch Operation

Standoff Cutting With Hand Torch

NOTE

For best performance and parts life, always use the

correct parts for the type of operation.

1. The torch can be comfortably held in one hand or

steadied with two hands. Position the hand to press

the Trigger on the torch handle. With the hand torch,

the hand may be positioned close to the torch head for

maximum control or near the back end for maximum

heat protection. Choose the holding technique that

feels most comfortable and allows good control and

movement.

NOTE

The tip should never come in contact with the

workpiece except during drag cutting operations.

2. Depending on the cutting operation, do one of the fol-

lowing:

a) For edge starts, hold the torch perpendicular

to the workpiece with the front of the tip on the

edge of the workpiece at the point where the cut

is to start.

b) For standoff cutting, hold the torch 1/8 - 3/8 in

(3-9 mm) from the workpiece as shown below.

A-00024_AB

Shield Cup

Torch

Standoff Distance

1/8" - 3/8" (3 - 9mm)

Standoff Distance

3. Hold the torch away from your body.

4. Slide the trigger release toward the back of the torch

handle while simultaneously squeezing the trigger. The

pilot arc will start.

A-02986

Trigger

Trigger Release

5. Bring the torch within transfer distance to the work.

The main arc will transfer to the work, and the pilot arc

will shut OFF.

NOTE

The gas preflow and postflow are a characteristic

of the power supply and not a function of the torch.

3

4

Art # A-03383

Trigger

2

1

Trigger Release

6. Cut as usual. Simply release the trigger assembly to

stop cutting.

7. Follow normal recommended cutting practices as

provided in the power supply operator's manual.

NOTE

When the shield cup is properly installed, there

is a slight gap between the shield cup and the

torch handle. Gas vents through this gap as part

of normal operation. Do not attempt to force the

shield cup to close this gap. Forcing the shield cup

against the torch head or torch handle can damage

components.