Cutmaster 12mm – Tweco CutMaster 12mm User Manual

Page 20

CUTMASTER 12mm

2T-2

INTRODUCTION

Manual 0-5076

G. Gas Requirements

Manual and Mechanized Torch Gas Specifications

Gas (Plasma and Secondary)

Compressed Air

Operating Pressure

Refer to NOTE

60 - 95 psi

4.1 - 6.5 bar

Maximum Input Pressure

125 psi / 8.6 bar

Gas Flow (Cutting and Gouging)

300 - 500 scfh

142 - 235 lpm

!

WARNING

This torch is not to be used with oxygen (O

2

).

NOTE

Operating pressure varies with torch model, op-

erating amperage, and torch leads length. Refer

to gas pressure settings charts for each model.

H. Direct Contact Hazard

For standoff tip the recommended standoff is 3/16 inches

/ 4.7 mm.

2T.04 Options And Accessories

For options and accessories, see section 6.

2T.05 Introduction to Plasma

A. Plasma Gas Flow

Plasma is a gas which has been heated to an extremely

high temperature and ionized so that it becomes electri-

cally conductive. The plasma arc cutting and gouging

processes use this plasma to transfer an electrical arc to

the workpiece. The metal to be cut or removed is melted

by the heat of the arc and then blown away.

While the goal of plasma arc cutting is separation of the

material, plasma arc gouging is used to remove metals to

a controlled depth and width.

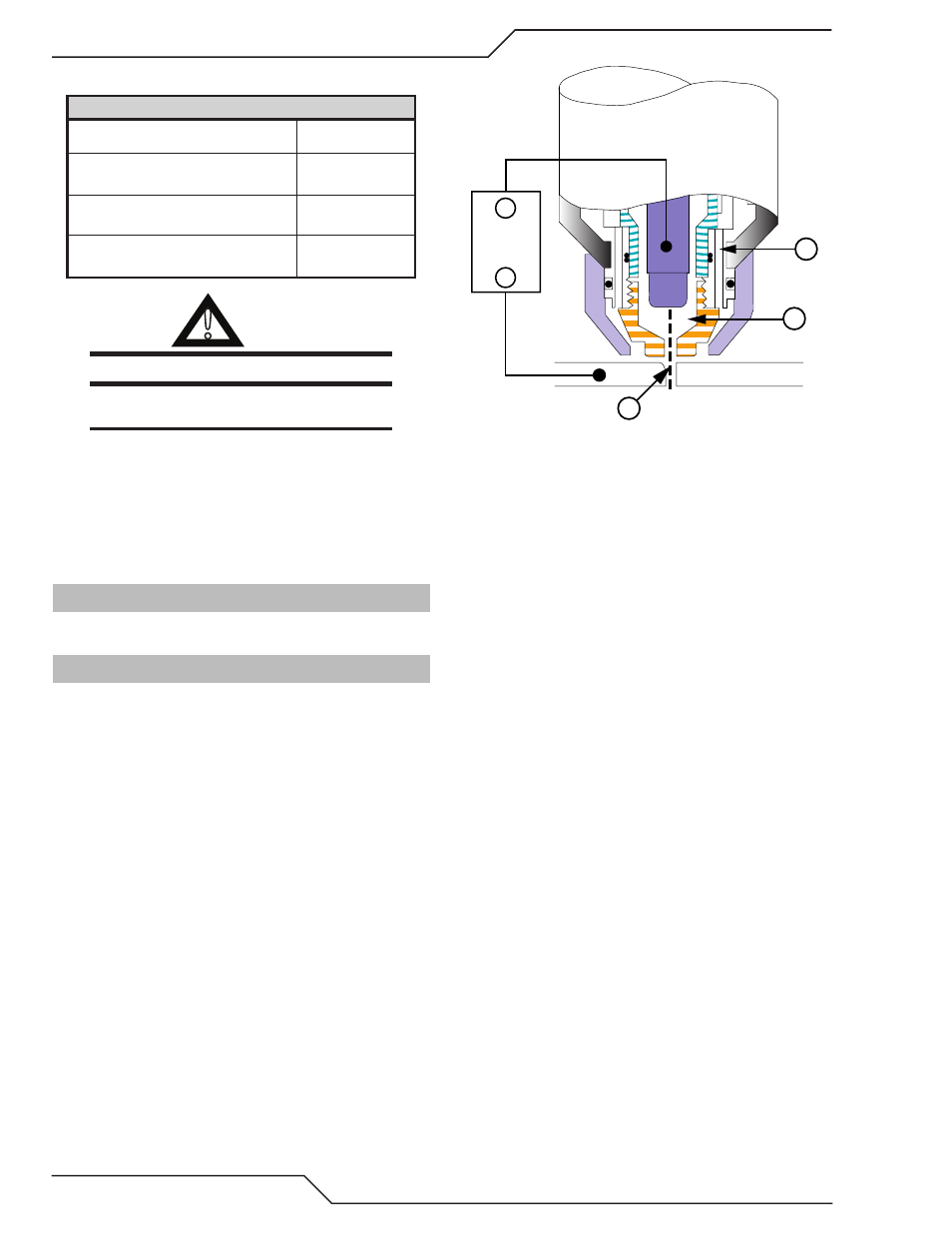

In a Plasma Cutting Torch a cool gas enters Zone B, where

a pilot arc between the electrode and the torch tip heats and

ionizes the gas. The main cutting arc then transfers to the

workpiece through the column of plasma gas in Zone C.

A-00002

Workpiece

Power

Supply

+

_

C

B

A

Typical Torch Head Detail

By forcing the plasma gas and electric arc through a small

orifice, the torch delivers a high concentration of heat to a

small area. The stiff, constricted plasma arc is shown in

Zone C. Direct current (DC) straight polarity is used for

plasma cutting, as shown in the illustration.

Zone A channels a secondary gas that cools the torch. This

gas also assists the high velocity plasma gas in blowing

the molten metal out of the cut allowing for a fast, slag -

free cut.

B. Gas Distribution

The single gas used is internally split into plasma and

secondary gases.

The plasma gas flows into the torch through the negative

lead, through the starter cartridge, around the electrode,

and out through the tip orifice.

The secondary gas flows down around the outside of the

torch starter cartridge, and out between the tip and shield

cup around the plasma arc.

C. Pilot Arc

When the torch is started a pilot arc is established between

the electrode and cutting tip. This pilot arc creates a path

for the main arc to transfer to the work.

D. Main Cutting Arc

DC power is also used for the main cutting arc. The nega-

tive output is connected to the torch electrode through

the torch lead. The positive output is connected to the

workpiece via the work cable and to the torch through a

pilot wire.