4t.05 gouging, 4t.05 gouging t-6 – Tweco CutMaster 12mm-20mm-25mm User Manual

Page 38

CUTMASTER 12mm, 20mm, 25mm

OPERATION 4T-6 Manual 0-5117

Piercing With Hand Torch

1. The torch can be comfortably held in one

hand or steadied with two hands. Position

the hand to press the Trigger on the torch

handle. With the hand torch, the hand

may be positioned close to the torch head

for maximum control or near the back end

for maximum heat protection. Choose the

technique that feels most comfortable and

allows good control and movement.

NOTE

The tip should never come in contact with

the workpiece except during drag cutting

operations.

2. Angle the torch slightly to direct blowback

particles away from the torch tip (and op-

erator) rather than directly back into it until

the pierce is complete.

3. In a portion of the unwanted metal start the

pierce off the cutting line and then continue

the cut onto the line. Hold the torch perpen-

dicular to the workpiece after the pierce is

complete.

4. Hold the torch away from your body.

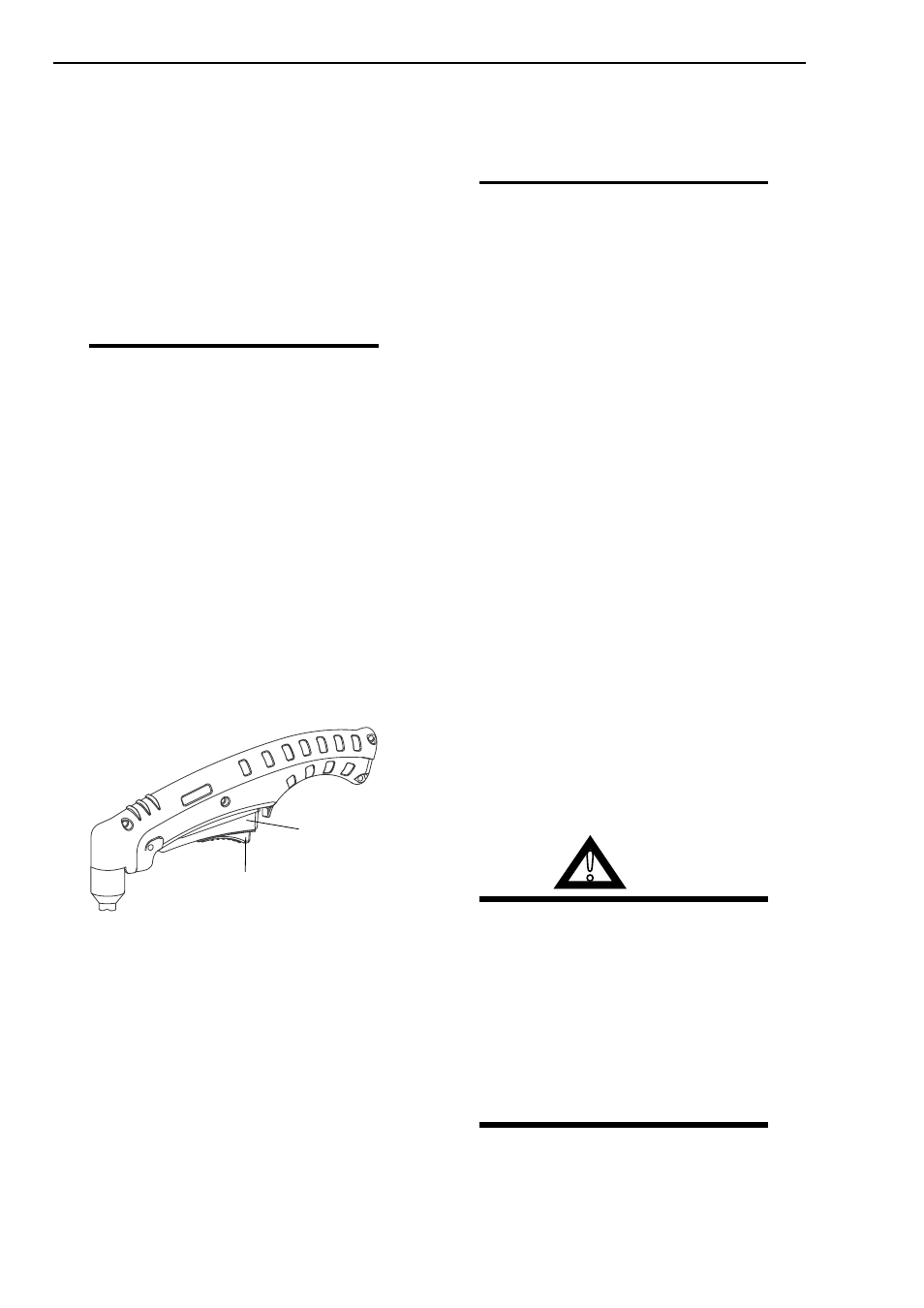

5. Slide the trigger release toward the back

of the torch handle while simultaneously

squeezing the trigger. The pilot arc will

start.

A-02986

Trigger

Trigger Release

6. Bring the torch within transfer distance to

the work. The main arc will transfer to the

work, and the pilot arc will shut OFF.

NOTES

The gas preflow and postflow are a char-

acteristic of the power supply and not a

function of the torch.

When the shield cup is properly installed,

there is a slight gap between the shield

cup and the torch handle. Gas vents

through this gap as part of normal opera-

tion. Do not attempt to force the shield

cup to close this gap. Forcing the shield

cup against the torch head or torch handle

can damage components.

7. Clean spatter and scale from the shield cup

and the tip as soon as possible. Spraying

the shield cup in anti - spatter compound

will minimize the amount of scale which

adheres to it.

Cutting speed depends on material, thickness,

and the operator’s ability to accurately follow

the desired cut line. The following factors may

have an impact on system performance:

• Torch parts wear

• Air quality

• Line voltage fluctuations

• Torch standoff height

• Proper work cable connection

4T.05 Gouging

!

WARNING

Be sure the operator is equipped with

proper gloves, clothing, eye and ear

protection and that all safety precau-

tions at the front of this manual have

been followed. Make sure no part of the

operator’s body comes in contact with the

workpiece when the torch is activated.

Disconnect primary power to the system

before disassembling the torch, leads, or

power supply.