Triton ABA 020 User Manual

Page 4

6

7

GB

GB

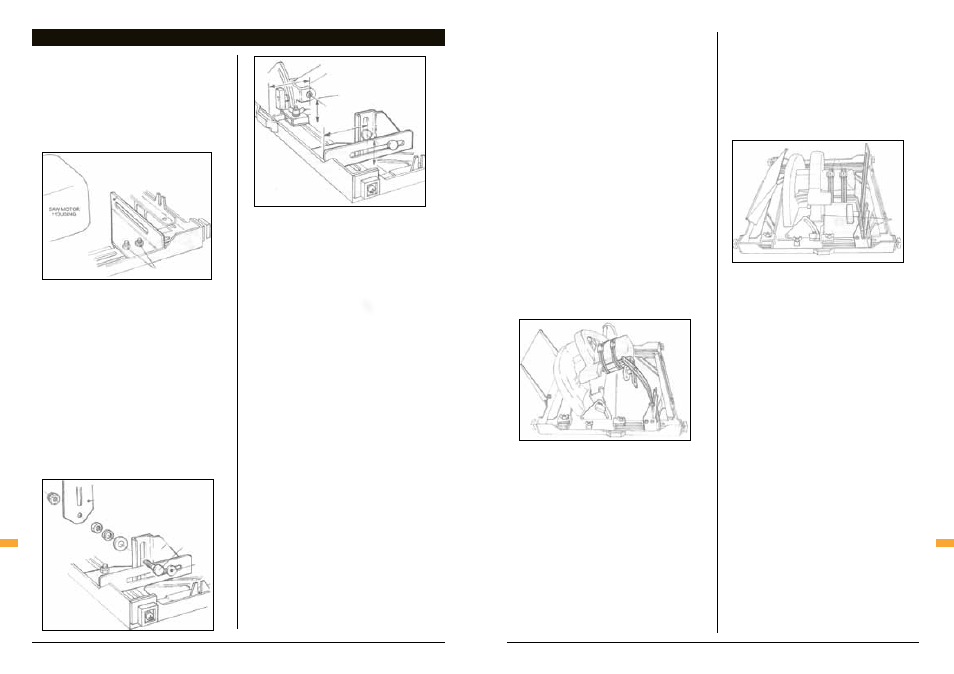

Fitting the Base Bracket

1. Loosely fit the Base Bracket (A) onto the slide

chassis, as in Fig 1, so that its vertical section is

in line with or just clear of the end of the saw’s

motor housing.

2. Use two of the ¼” x ½” Coach Bolts (I), Spring

Washers (K) and ¼” Nuts (J), and finger tighten

only.

Fitting the Pivot Mounting Bracket

1. Loosely attach the Pivot Mounting Bracket (B) to

the Base Bracket (A) using the remaining ¼” x

½” Coach Bolt (I), a Spring Washer (K) and a ¼”

Nut (J). Again, finger tighten only.

NOTE: Fig 2 shows the way in which the bracket is

attached, but the exact position of the bracket is

determined in the next steps.

2. Loosely fit the pivot bolt assembly - consisting

of a ¼” x ¾” Coach Bolt (H), the ¾” x 5/16” Flat

Washer (M), Spring Washer (K) and ¼” Nut (J) -

into the slot of the Pivot Mounting Bracket (B) as

shown in Fig 2.

NOTE: Do not yet fit Slotted Strap (C) and Nyloc Nut

(L) shown in Fig 2.

3. The next step is to ensure that this pivot bolt

assembly is in line with the saw’s front pivot,

both vertically and horizontally. This will enable

you to change the saw blade height without

having to change the stabilising bracket setting.

NOTE: Fig 3 shows the pivot bolt set in line with the

saw’s front pivot. It is possible to achieve this by

carefully lining up by eye, but it is preferable to

measure the relative pivot points from your slide

plate, as shown, using a ruler or measuring tape.

4. When the pivot bolt has been located correctly,

firmly tighten the nut, and also the nut fastening

the Pivot Mounting Bracket (B) to the Base

Bracket (A).

NOTE: If you have a vertical lift saw, this lining up

procedure is unnecessary. Simply locate the

pivot bolt low in its slot so that it will not foul the

T-Knob (G) to be fitted later.

5. Fit the Slotted Strap (C) onto the pivot bolt, using

the ¼” Nyloc Nut (L), as shown in Fig 2. Tighten

the nut so that the strap is firmly attached but

still free to pivot.

6. Position the strap so that it is approximately

vertical.

Fitting the Saw Motor Bracket

1. Slip the Band Clamps (D) over the saw motor

casing with the wormdrive fasteners on top

of the motor, and the screwdriver slots of the

wormdrives facing the rear. Do not fully tighten

the clamps yet.

2. The Saw Motor Bracket (E) has two arms, one

with a long slot and one with a short slot. For

most saws, fit the bracket with the short slotted

arm against the front of the motor casing.

3. Position the Rubber Cushion Strip (F) between

the motor casing and the bracket arm. Fit the arm

in position under the band clamps, and against

the rubber strip.

4. Position the long slotted arm of the bracket so

that it is touching the inside face of the Slotted

Strap (C).

5. Find the best positions on the motor casing for

the band clamps. Have the clamps as far apart

as you can, but avoid clamping too close to the

outside edge of the casing, especially if it is

tapered. Partially tighten the two band clamps.

6. Before fully tightening the clamps, fit the

remaining ¼” x ¾” coach bolt through the Slotted

Strap (C) and the slot in the Saw Motor Bracket

(E), fit the ¾” x ¼” flat washer, and fasten with

the T-Knob (T-Knob to the inside).

7. Check that the lower edge of the Saw Motor

Bracket (E) does not hit the Nyloc Nut (L) of

the pivot bolt assembly. You may need to move

the Saw Motor Bracket (E) slightly up the

motor casing. This bracket does not need to be

horizontal and may be angled slightly upwards to

provide increased clearance away from the pivot

bolt.

8. Before fully tightening all the fastenings, check

that the saw can be adjusted through its full

range in both depth of cut and angle of cut. Note

that the Slotted Strap (C) is designed to flex in a

curve when the saw is angled for bevel cutting,

see Fig 4.

9. If the saw can be adjusted smoothly through its

full range, loosen the T-Knob and fully tighten the

Band Clamps (D). Do not overtighten the band

clamps as you could damage the motor casing.

10. Also, ensure that the arm of the Saw Motor

Bracket (E) which extends forward is parallel to

the edge of the saw’s base plate, see Fig 5. If

it is not parallel, either remove the bracket and

slightly bend the bracket in a vice, or use shim

packing on one side between the rubber cushion

strip and the bracket.

11. Re-tighten the T-Knob (G), ensuring that the

Slotted Strap (C) remains in the vertical position,

and that the extended arm of the Saw Motor

Bracket (E) does not flex or distort as you tighten

the knob.

12. Finally, tighten the nuts fastening the Base

Bracket (A) to the slide chassis.

Assembly

Assembly

ASSEMBLY

Fig: 1

Fig: 2

Fig: 3

Fig: 4

Fig: 5