Settings, Room temperature unit (rtu) and indoor sensor, Unoccupied switch – tekmar 352 House Control User Manual

Page 6: Maximum system supply, Heating curve, Unoccupied temperature, Dip switch setting boiler — injection

Copyright © D 352 - 06/00

6 of 8

Room Temperature Unit (RTU) and Indoor Sensor

Connect the two wires from either the RTU 054 or the Indoor Sensor 076 to the

RTU Sen — Com Sen

(6 and 7) terminals. The RTU or Indoor Sensor provides indoor temperature feedback.

Unoccupied Switch

If an external timer or switch is used, connect the two wires from the external dry contact switch to the

UnO

Sw — Com Sen (5 and 7) terminals. When these terminals short together, the control registers an

UnOccupied signal. For more information on the tekmar Timer 031 consult its Data Brochure D 031.

Settings

Before adjusting the dial settings, read through the sequence of operation to ensure that you understand how the control operates.

STEP SIX

ESSENTIAL CONTROL SETTINGS

Minimum Boiler Supply

Most boilers require a minimum operating temperature to prevent corrosion from flue gas condensation. If the 352 is in

Boiler mode,

the

Min. Boiler Supply dial should be set to the lowest supply water temperature at which the boiler can operate without causing the

boiler flue gases to condense. Consult the boiler manufacturer for recommended minimum boiler supply temperatures. Some typical

settings are given below. If a condensing or electric boiler is used, the

Min. Boiler Supply dial should be set to Off.

Typical settings:

• Steel fire tube boilers …..........140 to 160

°F (60 to 71°C)

• Cast iron boilers …..................135 to 160

°F (57 to 71°C)

• Copper tube boilers ….............135 to 150

°F (57 to 66°C)

Maximum System Supply

If the 352 is used in

Injection mode, the 352 helps prevent the mixed supply water temperature from rising

above the

Max. Supply dial setting. The Max. Supply dial should be set to the maximum temperature allowed

in the system loop. There are many factors which may limit the allowable supply temperature in a radiant

floor heating system. A few of these are provided below.

• Some tubing manufacturers recommend that their products not be maintained at temperatures exceeding

140

°F (60°C). Consult the tubing manufacturer for specific details.

• No where in the concrete should the temperature be maintained above 170

°F (77°C).

• The surface temperature of a radiant floor heating slab should normally not exceed 85

°F (29°C). The slab surface temperature is

affected by the slab thermal resistance, the heating load, and the supply water temperature to the slab.

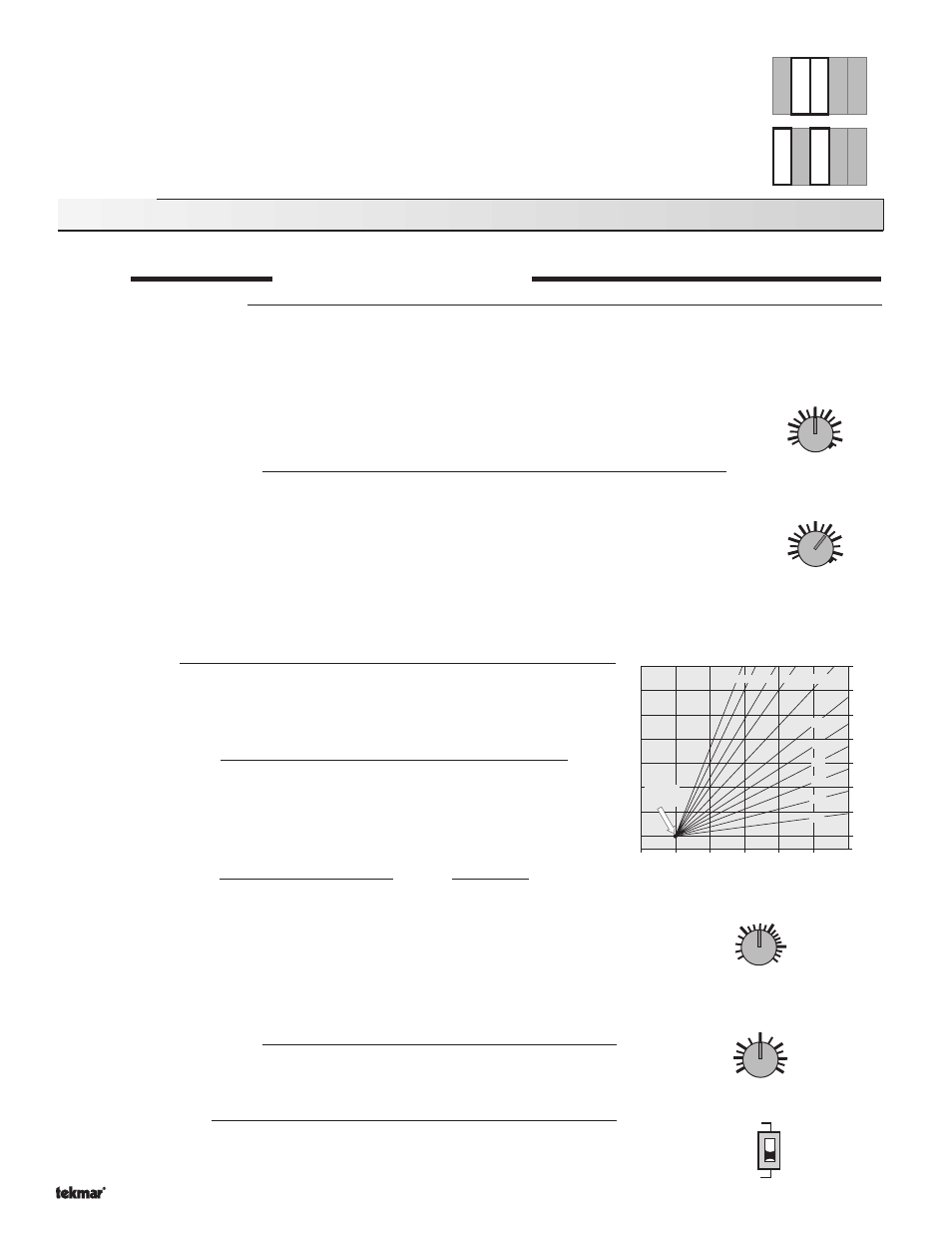

Heating Curve

The Heating Curve setting determines the number of degrees the supply water tempera-

ture is raised for every one degree drop in outdoor temperature. The

Heating Curve dial

position can be calculated from the following formula.

design supply temperature – desired room temperature

Heating Curve

=

desired room temperature – design outdoor temperature

Example: A system is designed to supply 120

°F water when the outdoor temperature is

10

°F. The desired room temperature is 70°F.

120

°F - 70°F (49°C - 21°C)

50

°F (28°C)

Heating Curve

=

=

= 0.8

70

°F - 10°F (21°C - (-12°C))

60

°F (33°C)

If the design supply water temperature is unknown, the

Heating Curve dial can be set to

a trial value using the typical design supply temperatures given below.

Typical design supply temperatures:

• Hydronic radiant floors … 100 to 130

°F (38 to 54°C)

• Baseboard convectors … 160 to 190

°F (71 to 88°C)

• Fan coils ………………… 180 to 210

°F (82 to 99°C)

Unoccupied Temperature

The

UnOccupied dial sets the desired indoor temperature during UnOccupied (Night

Setback) mode. If no indoor temperature feedback is used, the dial determines the

heating curve starting point during the UnOccupied period.

DIP Switch Setting

Boiler — Injection

If boiler operation is required, the DIP switch must be set to

Boiler. If mixing operation

is required, the DIP switch must be set to

Injection.

RTU

Sen

6

8

Sup

Sen

UnO

Sw

5

Com

Sen

7

Out

Sen

9

RTU

Sen

6

8

Sup

Sen

UnO

Sw

5

Com

Sen

7

Out

Sen

9

Outdoor air temperature

50

(10)

30

(-1)

10

(-12)

-10

(-23)

70

(21)

3.6 3.0 2.4 2.0

1.6

1.2

0.8

0.4

1.0

0.6

90

(32)

WWSD

Point

°F

(

°C)

Supply water temperature

110

(43)

70

(21)

90

(32)

210

(99)

170

(77)

150

(65)

130

(54)

190

(88)

0.2

0.2

2

3.6

1

3

Heating Curve

70

°F (21°C)

40 (4)

100 (38)

UnOccupied

Injection

Boiler

140

°F

170

Min. Boiler /

Max. Supply

105

Off

140

°F

170

Min. Boiler /

Max. Supply

105

Off