Heating curve, Heating curve parallel shift, Indoor temperature feedback – tekmar 352 House Control User Manual

Page 2: Warm weather shut down (wwsd), Boiler operation, Minimum boiler supply, Boiler differential, Mixing operation

Copyright © D 352 - 06/00

2 of 8

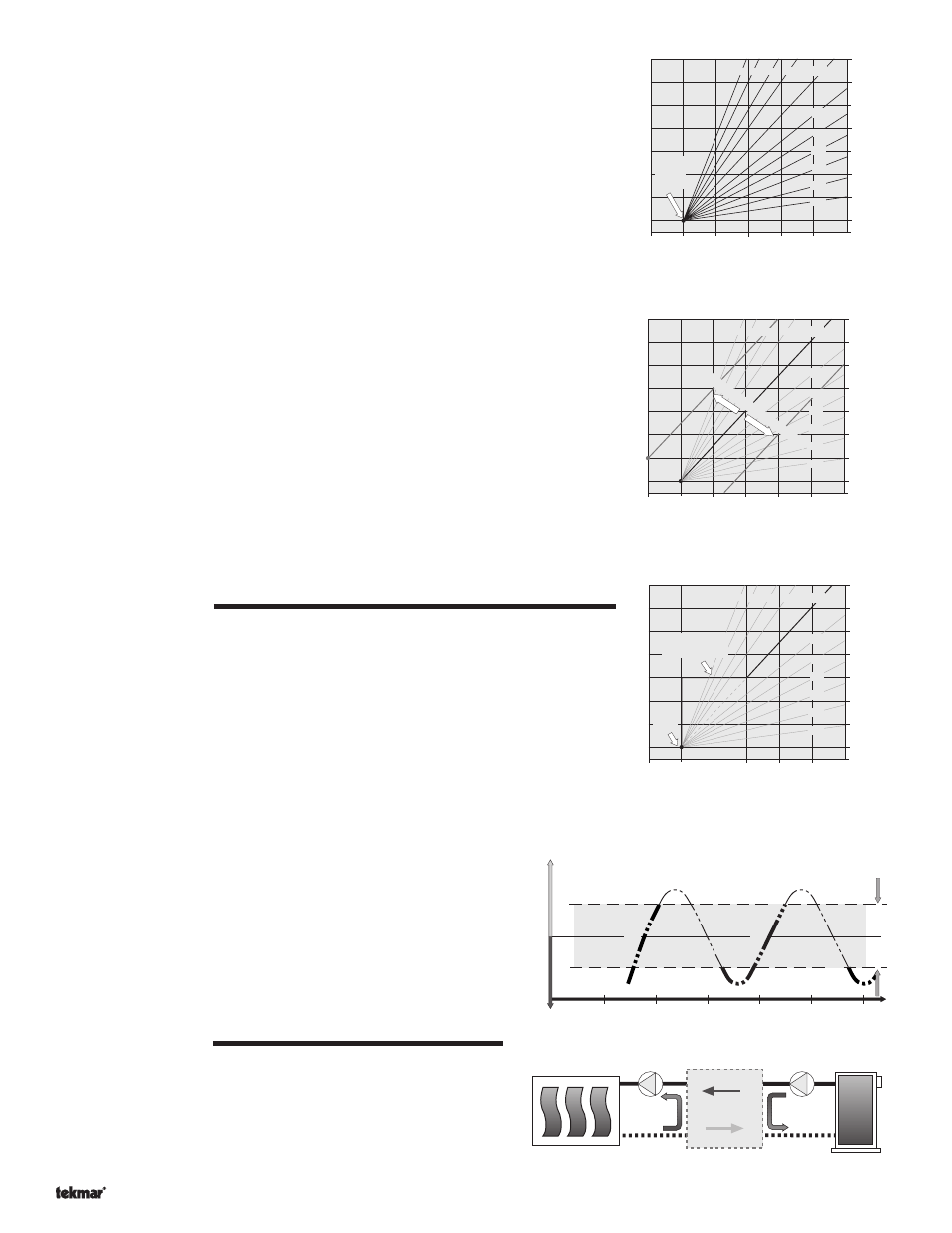

Heating Curve

A hot water heating system can be accurately controlled by modulating the supply water

temperature as the outdoor temperature changes. Using this approach the heat lost from

the building is exactly matched by the heat input to the building. A tekmar reset control

utilizes a heating curve to set the relationship between outdoor temperature and supply

water temperature. The heating curve determines the amount the supply water tempera-

ture is raised for every 1

° drop in outdoor air temperature. The heating curve is sometimes

called an outdoor reset ratio.

Heating Curve Parallel Shift

All heating curves begin at the heating curve starting point. If the heating curve starting

point is adjusted, the heating curve will be parallel shifted. The heating curve starting point

is either set manually through a dial, or it is determined automatically by the control

through indoor temperature feedback.

Indoor Temperature Feedback

Most buildings have internal heat gains due to people, passive solar heating and

mechanical or electrical equipment. If only the outdoor temperature is measured, the

control cannot compensate for these internal heat gains and the building may overheat.

In order to prevent overheating, indoor temperature feedback should be combined with

the outdoor reset strategy. From this indoor temperature feedback, the control can

change the heating curve starting point in order to match the supply water temperature

to the heat loss of the building. If the indoor temperature is too warm, the control

automatically shifts the starting point and the heating curve down. If the indoor tempera-

ture is too cold, the control shifts the starting point and heating curve up.

Warm Weather Shut Down (WWSD)

When the outdoor temperature is equal to the heating curve starting point, no additional

heat is required in the building and therefore the heating system can be shut down. The

WWSD point is normally the same as the heating curve starting point.

BOILER OPERATION

The supply water temperature from a boiler can be controlled by cycling the boiler on and

off. Modulation of the boiler’s operating temperature in hot water heating systems not only

provides more comfort but also offers significant energy savings. The cooler the boiler runs,

the more efficient it is due to less heat losses up the flue and reduced boiler jacket losses.

Minimum Boiler Supply

Most boilers require a minimum supply water temperature in order to prevent corrosion

from flue gas condensation. The control should therefore only modulate the boiler supply

water temperature down to the boiler manufacturer’s minimum recommended operating

temperature. Some boilers are designed to condense and should be operated at low

water temperatures as much as possible for maximum efficiency.

Boiler Differential

An on / off boiler must be operated with a differential in order to prevent

short cycling. When the supply water temperature drops below the

bottom rail of the differential, the boiler is turned on. The boiler is then

kept on until the supply water temperature rises above the top rail of

the differential. If the differential is too wide, there can be large supply

water temperature swings; however, if the differential is too narrow, the

boiler short cycles and operates inefficiently. Some controls automati-

cally calculate the boiler differential in order to achieve an appropriate

balance between temperature swings and boiler efficiency. This also

permits the control to adapt to changing loads and conditions.

MIXING OPERATION

The full range of water temperatures required through a heating season

can be provided with a standard (non-condensing) boiler by incorporat-

ing a mixing device into the system. An On / Off Injection Valve or Pump

can be used to modulate the system supply water temperature to

improve comfort in the building and provide a maximum target supply

water temperature limit. For more detailed information on mixing meth-

ods consult Essay E 021.

Outdoor air temperature

50

(10)

30

(-1)

10

(-12)

-10

(-23)

70

(21)

3.6 3.0 2.4 2.0

1.6

1.2

0.8

0.4

1.0

0.6

90

(32)

Heating

Curve

Starting

Point

°F

(

°C)

Supply water temperature

110

(43)

70

(21)

90

(32)

210

(99)

170

(77)

150

(65)

130

(54)

190

(88)

0.2

Supply W

ater

T

emperature

Time

Differential = 10

°F (5°C)

165

°F(74°C)

B

o

ile

r

o

ff

B

o

ile

r

o

n

155

°F (68°C)

160

°F (71°C)

B

o

ile

r

o

ff

B

o

ile

r

o

n

Mixing

Device

Boiler

Loop

System

Loop

Outdoor air temperature

50

(10)

30

(-1)

10

(-12)

-10

(-23)

70

(21)

3.6 3.0

2.0

1.6

1.2

0.8

0.4

0.6

90

(32)

°F

(

°C)

Supply water temperature

110

(43)

70

(21)

90

(32)

210

(99)

170

(77)

150

(65)

130

(54)

190

(88)

2.4

1.0

WWSD

Point

70

°F

Minimum Boiler

Supply Setting

130

°F

0.2

Outdoor air temperature

50

(10)

30

(-1)

10

(-12)

-10

(-23)

70

(21)

3.6 3.0

2.0

1.6

1.2

0.8

0.4

0.6

90

(32)

°F

(

°C)

Supply water temperature

110

(43)

70

(21)

90

(32)

210

(99)

170

(77)

150

(65)

130

(54)

190

(88)

2.4

1.0

UP

DOWN

Parallel Shift of Heating Curve

0.2