Retract landing gear installation (optional) – E-flite Beechcraft Staggerwing 480 ARF User Manual

Page 9

9

E-flite Beechcraft 480 Staggerwing 480 ARF Assembly Manual

Retract Landing

Gear Installation (Optional)

Required parts

Bottom wing

Transmitter

Receiver

Receiver battery

Servo with hardware

Retract set

2-56 x 1/2-inch machine screw (2)

Landing gear assembly (right and left)

Landing gear door (right and left)

2mm x 5mm self-tapping countersunk screw (8)

Required Tools and Adhesives

Medium CA

Phillips screwdriver: #1

Pliers

Hobby knife with #11 blade

Ruler

Side cutters

Hobby scissors

Sandpaper

Hex wrench: 1.5mm Silicone adhesive

The landing gear can be left off of your model,

allowing you to hand-launch and belly-land the

airplane. If you choose to do so, skip the landing

gear installation and continue the assembly of your

model at the Horizontal Stabilizer Installation section.

1. Use a #0 Phillips screwdriver to remove the stock

servo horn from the servo. Center the aileron servo

using the radio system. Install the single-sided horn

so it is perpendicular to the servo centerline. Install

the screw to secure the horn using a #0 Phillips

screwdriver

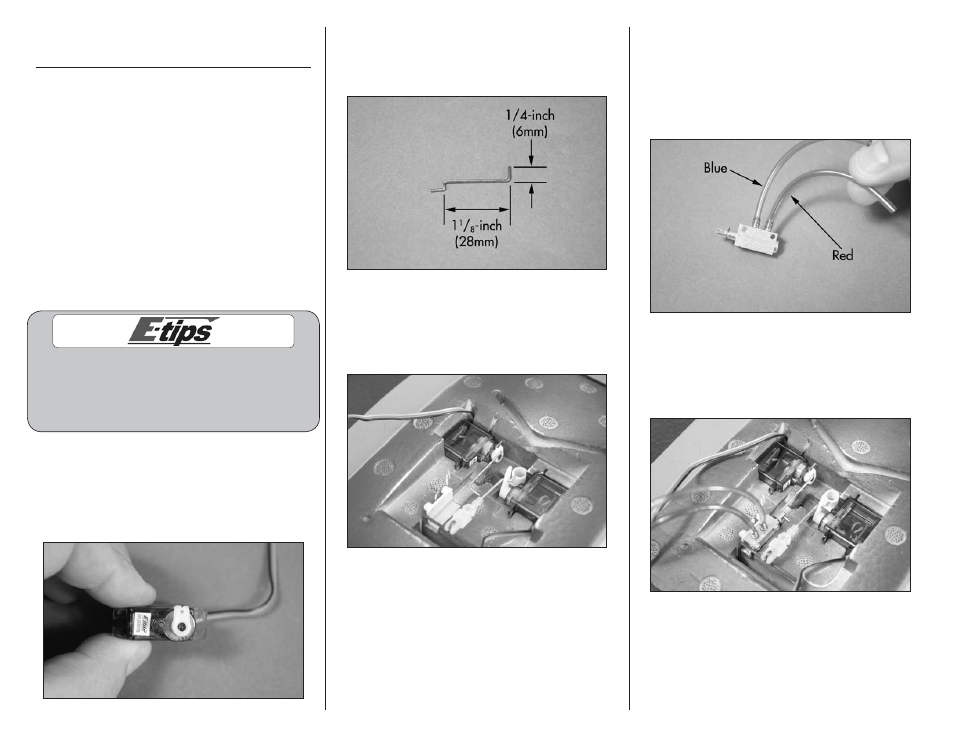

2. Use pliers to bend the pushrod included with the

retracts so it measures 1

1

/

8

-inch (28mm) in length.

Use side cutters to trim the linkage so 1/4-inch (6mm)

extends past the bend.

3. Insert the Z-bend in the servo horn. The retract

servo is then installed in the wing with the output shaft

oriented towards the leading edge as shown using

a drop of medium CA. Don’t over-glue the servo in

case it requires removal in the future.

4. The nipples on the retract valve are offset slightly.

Below, it is visible that the stopper end of the valve

plunger orients TOWARDS the side where the nipple

is the closest. Cut a 3-inch section of red airline and

another of blue. These will be trimmed if required

later. Connect the blue air line to the left nipple and

the red airline to the right one as shown below.

5. Insert the end of the linkage in the hole of the

retract valve actuator. The valve is then secured

in the wing using two 2-56 x 1/2-inch machine

screws included with the retracts and a #1 Phillips

screwdriver.