Before starting assembly, Aileron servo installation – E-flite Beechcraft Staggerwing 480 ARF User Manual

Page 5

5

E-flite Beechcraft 480 Staggerwing 480 ARF Assembly Manual

Before Starting Assembly

Before beginning the assembly of your model, remove

each part from its bag for inspection. Closely inspect

the fuselage, wing panels, rudder and stabilizer for

damage. If you find any damaged or missing parts,

contact the place of purchase.

During the course of building your model, we

suggest you use a soft base for the building surface.

Such things as a foam stand, large piece of

bedding foam or a thick bath towel will work well

and help protect the model from damage during

assembly. This is not shown in the instructions in

order to provide the greatest detail in the photos.

When referencing directions (up, down, left,

right, top and bottom), these directions are in

relationship to the pilot sitting in the cockpit

of the aircraft, unless noted otherwise.

NOTICE: Do not use a CA accelerator during

the assembly of your model. A CA accelerator will

damage the finish of your model and can damage

the foam as well. Even foam-safe accelerators will

damage the finish of your model. Allow the CA to

cure without the use of an accelerant.

Aileron Servo Installation

Required parts

Top wing

Transmitter

Receiver

Receiver battery

40mm pushrod with clevis (2)

Servo with hardware

Required Tools and Adhesives

Phillips screwdriver: #0

Hobby knife with #11 blade

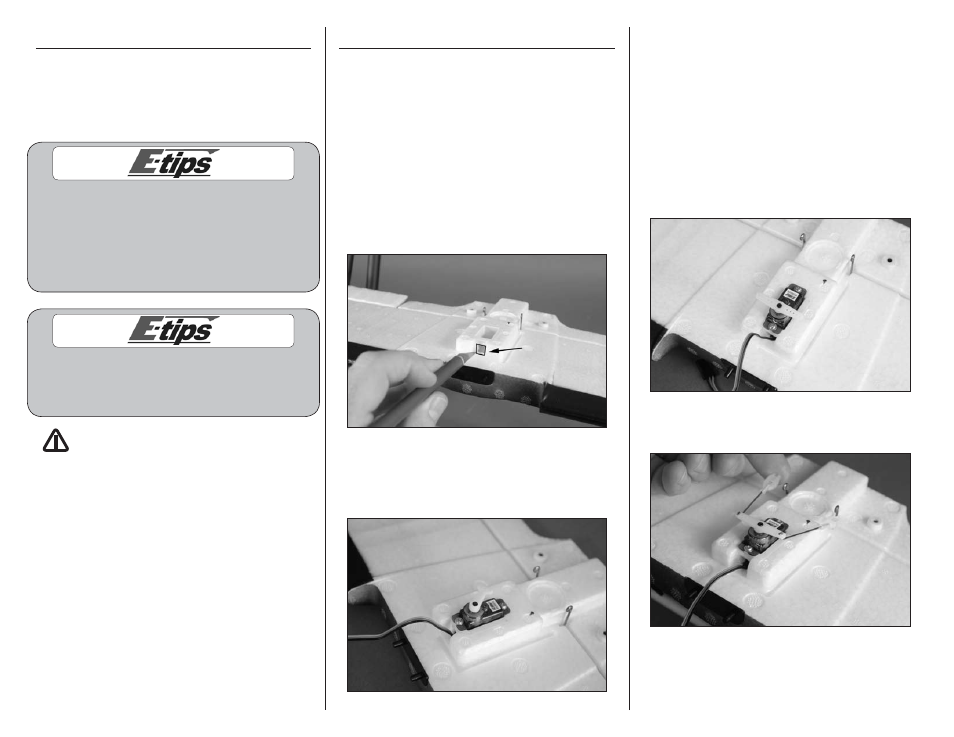

1. Use a hobby knife with a #11 blade to remove the

material below the aileron servo tray. The servo lead

will pass through this opening.

2. Install the aileron servo using the screws provided

with the servo and a #0 Phillips screwdriver. Make

sure the output shaft of the servo faces to the

leading edge of the wing.

Due to the molding process, foam may

cover one of the mounting holes in the

plastic aileron mount. There are two screw

holes; if one of them is obscured, you can

locate it with something like a T-pin.

3. Use a #0 Phillips screwdriver to remove the

stock servo horn from the servo. Center the aileron

servo using the radio system. Install the two-sided

horn so it is perpendicular to the servo centerline.

Install the screw to secure the horn using a #0

Phillips screwdriver.

4. Insert the Z-bend of the 40mm pushrods in the

outer holes of the servo horn as shown.