Elevator and aileron servo installation – E-flite F-16 400 DF ARF User Manual

Page 9

9

E-flite F-16 ARF Assembly Manual

8. Use two 2mm x 12mm self-tapping screws and

a #1 Phillips screwdriver to secure the stabilizer

to the fuselage. Use care not to over-tighten the

screws and cause damage to the fuselage or

stabilizer.

9. Repeat Steps 6 through 8 to attach the

remaining stabilizer to the fuselage.

Note: The stabilizer tips will be lower than the

center of the stabilizer at the fuselage when the

fuselage is upright. This is scale for the F-16

and is correct.

Elevator and Aileron Servo Installation

Required Parts

Servo (4)

Assembled airframe

Radio system

Fuselage decal (right and left)

Standard single-sided servo arm (4)

2

7

/

8

-inch (73mm) pushrod wire w/clevis (2)

5

7

/

8

-inch (150mm) pushrod wire w/clevis (2)

There are to different sets of servo extensions listed

for the F-16. The high power setup requires a

different length of extensions so that the receiver

can be placed farther forward and the battery in

the aft compartment to achieve the correct CG.

Required for Sport Ducted Fan:

3-inch (76mm) servo extension (2)

9-inch (228mm) servo extension (2)

Required for High-Power Ducted Fan:

6-inch (152mm) servo extension (2)

12-inch (305mm) servo extension (2)

Required Tools and Adhesives

6-minute epoxy

Mixing cup

Mixing stick

Epoxy brush

Paper towel

Rubbing alcohol

Sandpaper

Pin drill

Dental Floss/String Felt-tipped pen

Drill bit: 1/16-inch (1.5mm)

Phillips screwdriver: #00

Hobby knife w/#11 blade

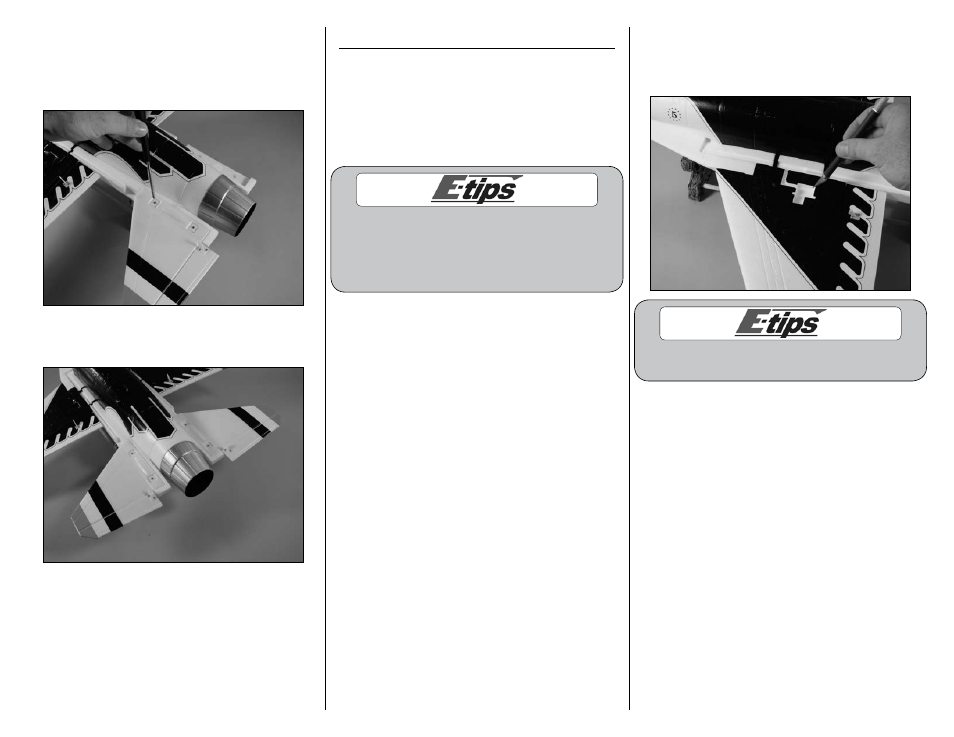

1. Use a hobby knife to trim the decal on the

bottom of the wing to expose the pocket for the

aileron servo. Prepare both the right and left wing

at this time.

You can use compressed air to blow

away the remains of the decal.

Note: Before preparing the aileron and

elevator servos for installation, it is suggested

to read through the Radio Programming

section of this manual beginning on Page

18. This section will guide you through

setting up the necessary mixing required to

operate the servos installed in your F-16. This

mixing reduces the amount of complexity and

extensions required, keeping the weight at its

lowest for the best performance for your model.