E-flite LR-1A Pogo ARF 15e User Manual

Page 6

10

E-flite LR-1A Pogo 15e ARF Assembly Manual

11

E-flite LR-1A Pogo 15e ARF Assembly Manual

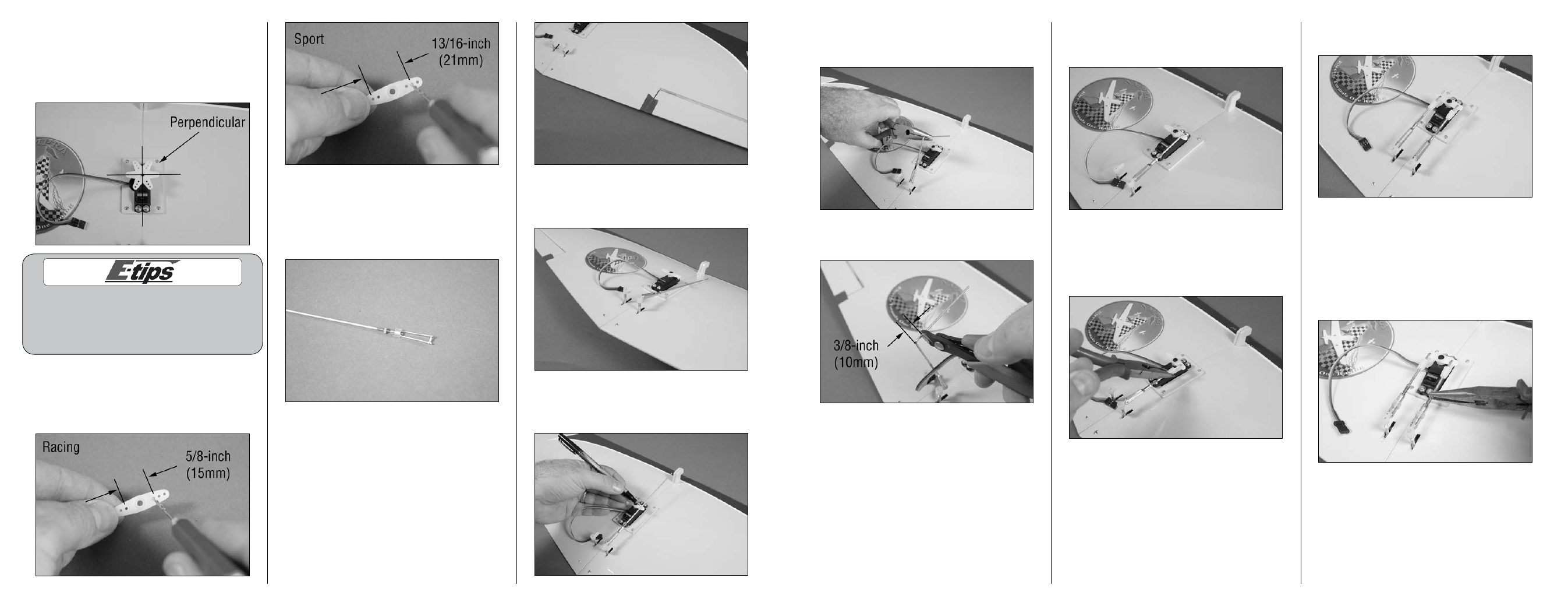

18. Use needle nose pliers to bend the pushrod

wire 90-degrees at the mark made in the previous

step.

19. Use side cutters to trim the wire 3/8-inch

(10mm) from the bend as shown.

20. Insert the linkage wire into the appropriate

hole in the servo horn for your particular flying

application.

21. Secure the linkage to the servo horn using a

nylon pushrod keeper. Slide the keeper on the bend

of the wire under the horn, then use pliers to snap

the rear portion of the keeper onto the linkage

wire.

22. Repeat Steps 14 through 21 to install the

remaining linkage.

23. Remove the low-tack tape from the ailerons.

Use the radio to check the operation of the

ailerons. Adjust the clevises if necessary so both

ailerons are centered when the servo is centered.

Use pliers to tighten the nut against the clevis to

prevent the clevis from changing positions in flight.

Slide the silicone keepers over the forks of the clevis

to keep them from accidentally opening in flight.

24. Disconnect the power and servo from the

receiver and turn the transmitter off at this time.

12. Use the radio system to center the aileron

servo. Install the servo horn so it is perpendicular to

the servo center line as shown. The servo horn has

an odd number of splines, so rotate it until the arms

are aligned, rather than using the sub-trim function

from the radio.

When installing the aileron linkage there are two

locations we suggest. One is for racing, making

the aircraft smoother and easier to control.

The other position is for general sport flying

which makes the aircraft more responsive.

13. Remove the servo horn from the servo. Use

side cutters to remove any unused arm from the

horn. Use a pin vise and 5/64-inch (2mm) drill

bit to enlarge the appropriate holes in the horn as

shown.

14. Slide a silicone keeper on the metal clevis.

Thread the nut on the 4

3

/

4

-inch (120mm) linkage

wire back so the metal clevis can be installed.

The threads on the linkage should just be visible

between the forks of the clevis.

15. Use a piece of low-tack tape to keep the

aileron centered when installing the linkage.

16. Use a flat blade screwdriver to open the forks

of the clevis enough to connect it to the aileron

control horn.

17. Use a felt-tipped pen to mark the linkage wire

where it crosses the appropriate hole in the servo

horn.